Question: Kelley, Inc. is preparing an aggregate production plan for the next year. The company expects demand to be 1,000 units in quarter 1; 2,000 units

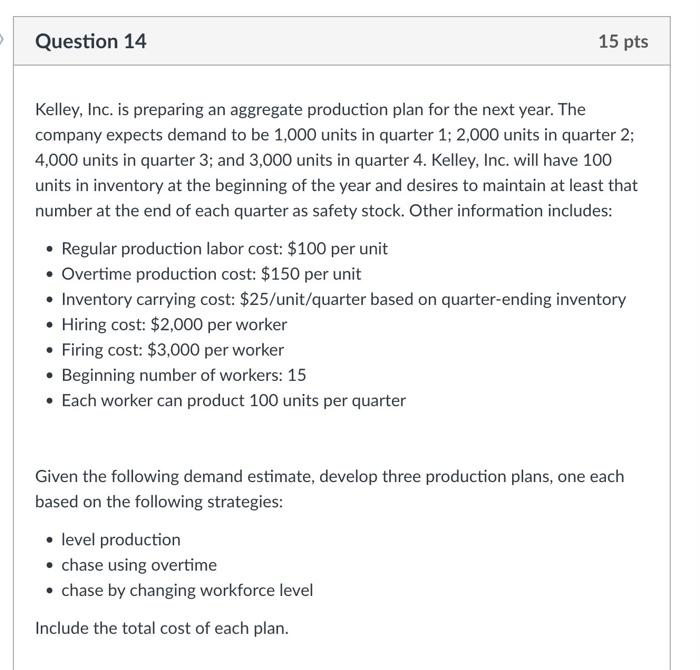

Kelley, Inc. is preparing an aggregate production plan for the next year. The company expects demand to be 1,000 units in quarter 1; 2,000 units in quarter 2; 4,000 units in quarter 3; and 3,000 units in quarter 4. Kelley, Inc. will have 100 units in inventory at the beginning of the year and desires to maintain at least that number at the end of each quarter as safety stock. Other information includes:

- Regular production labor cost: $100 per unit

- Overtime production cost: $150 per unit

- Inventory carrying cost: $25/unit/quarter based on quarter-ending inventory

- Hiring cost: $2,000 per worker

- Firing cost: $3,000 per worker

- Beginning number of workers: 15

- Each worker can product 100 units per quarter

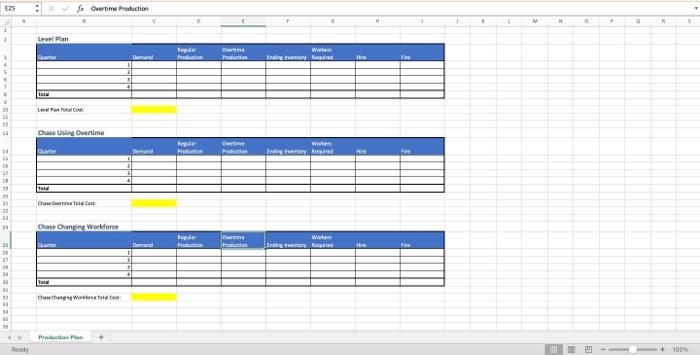

Given the following demand estimate, develop three production plans, one each based on the following strategies:

- level production

- chase using overtime

- chase by changing workforce level

Include the total cost of each plan.

Question 14 15 pts Kelley, Inc. is preparing an aggregate production plan for the next year. The company expects demand to be 1,000 units in quarter 1; 2,000 units in quarter 2; 4,000 units in quarter 3; and 3,000 units in quarter 4. Kelley, Inc. will have 100 units in inventory at the beginning of the year and desires to maintain at least that number at the end of each quarter as safety stock. Other information includes: Regular production labor cost: $100 per unit Overtime production cost: $150 per unit Inventory carrying cost: $25/unit/quarter based on quarter-ending inventory Hiring cost: $2,000 per worker Firing cost: $3,000 per worker Beginning number of workers: 15 Each worker can product 100 units per quarter Given the following demand estimate, develop three production plans, one each based on the following strategies: level production chase using overtime chase by changing workforce level Include the total cost of each plan. EZS 4 2 * 14 st 4 14 ====== 19 22 23 24 25 24 27 2 21 31 31 32 n 34 25 31 A Ready fr Overtime Production Demand Level Plan Curr LTC Chase Using Overtime Qur Tod hair Tutal Cam:- Chase Changing Workforce Quinter Tatal Chase Changing Work Production Plan C Demand D Irglar Iadulton Regular Production Teglar Production De Dertine Production Dertine Production Work Endinery an Workers Ingry login Work Ending inery Reque B H4 15 Tee Fre Tax X K A M [E = 0 ET P 0 M 100% Question 14 15 pts Kelley, Inc. is preparing an aggregate production plan for the next year. The company expects demand to be 1,000 units in quarter 1; 2,000 units in quarter 2; 4,000 units in quarter 3; and 3,000 units in quarter 4. Kelley, Inc. will have 100 units in inventory at the beginning of the year and desires to maintain at least that number at the end of each quarter as safety stock. Other information includes: Regular production labor cost: $100 per unit Overtime production cost: $150 per unit Inventory carrying cost: $25/unit/quarter based on quarter-ending inventory Hiring cost: $2,000 per worker Firing cost: $3,000 per worker Beginning number of workers: 15 Each worker can product 100 units per quarter Given the following demand estimate, develop three production plans, one each based on the following strategies: level production chase using overtime chase by changing workforce level Include the total cost of each plan. EZS 4 2 * 14 st 4 14 ====== 19 22 23 24 25 24 27 2 21 31 31 32 n 34 25 31 A Ready fr Overtime Production Demand Level Plan Curr LTC Chase Using Overtime Qur Tod hair Tutal Cam:- Chase Changing Workforce Quinter Tatal Chase Changing Work Production Plan C Demand D Irglar Iadulton Regular Production Teglar Production De Dertine Production Dertine Production Work Endinery an Workers Ingry login Work Ending inery Reque B H4 15 Tee Fre Tax X K A M [E = 0 ET P 0 M 100%

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts