Question: L M N O A B C D E 1 Make-Buy decision The company, a wind sailing board manufacturer, is currently operating at 70% capacity

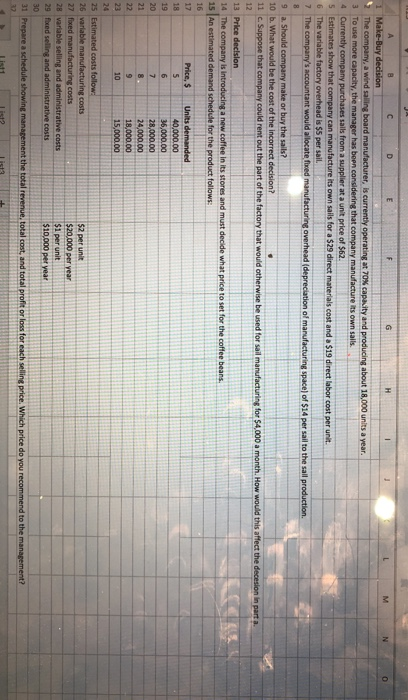

L M N O A B C D E 1 Make-Buy decision The company, a wind sailing board manufacturer, is currently operating at 70% capacity and producing about 18,000 units a year. 3 To use more capacity, the manager has been considering that company manufacture its own sails. 4 Currently company purchases sails from a supplier at a unit price of $62 S Estimates show that company can manufacture its own sails for a $29 direct materials cost and a $19 direct labor cost per unit 6 The variable factory overhead is $5 per sail. 7 The company's accountant would allocate fred manufacturing overhead (depreciation of manufacturing space of $14 per sail to the sail production. 9 a. Should company make or buy the sails? 10 b. What would be the cost of the incorrect decision? 11 c. Suppose that company could rent out the part of the factory that would otherwise be used for sail manufacturing for $4,000 a month. How would this affect the decesion in part a. 12 13 Price decision 14 The company is introducing a new coffee in its stores and must decide what price to set for the coffee beans. 15 An estimated demand schedule for the product follows: Price, $ Units demanded 40,000.00 36,000.00 28,000.00 24,000.00 18,000.00 15,000.00 25 Estimated costs follow: 26 variable manufacturing costs 27 fixed manufacturing costs ZB variable selling and administrative costs 29 foed selling and administrative costs $2 per unit $20,000 per year $1 per unit $10,000 per year 31 Prepare a schedule showing manapement the total revenue, total cost, and total profit or loss for each selling price. Which price do you recommend to the management? list1 list? list

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts