Question: Lean Pacing Lamp project Need your help; please. Can you lay out the storeroom? Storeroom and Inventory (Kanban) Workstation Design (with Ergonomics) Figure 9: Chassis

Lean Pacing Lamp project

Need your help; please.

Can you lay out the storeroom?

Storeroom and Inventory (Kanban)

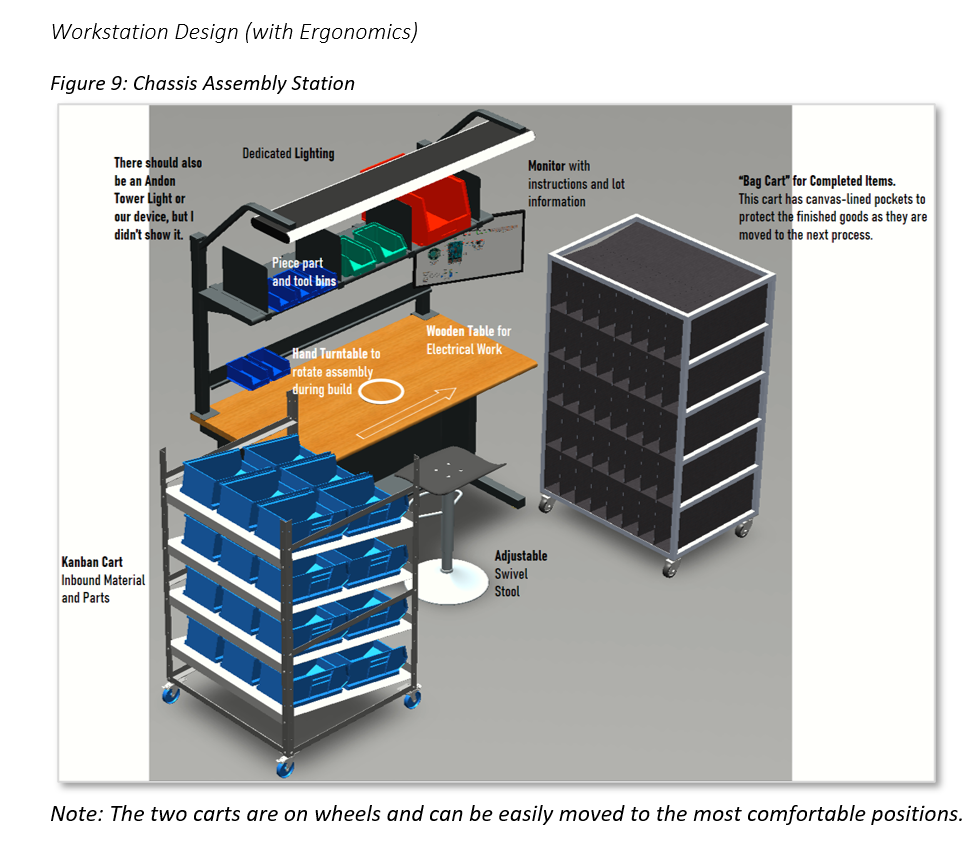

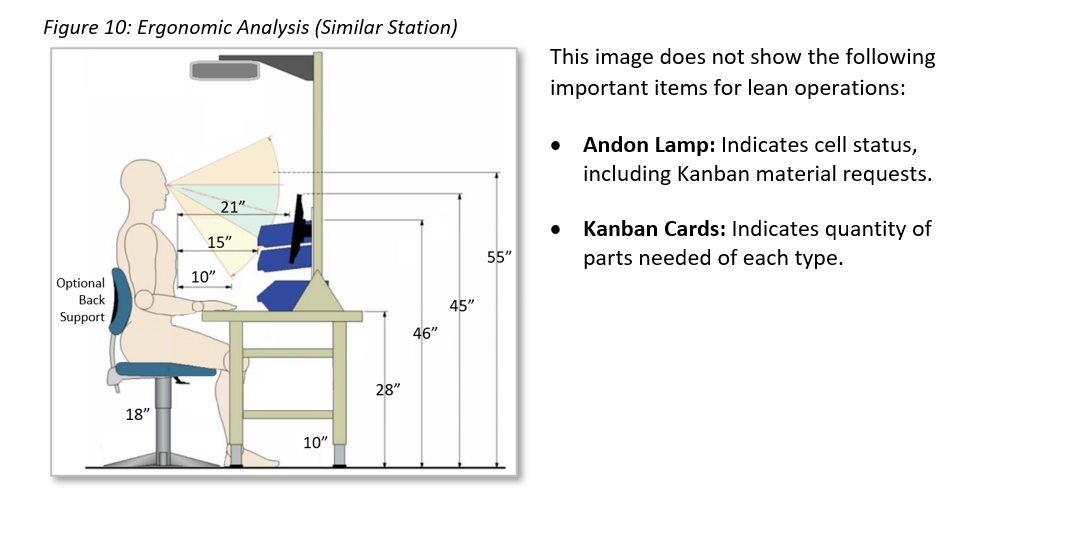

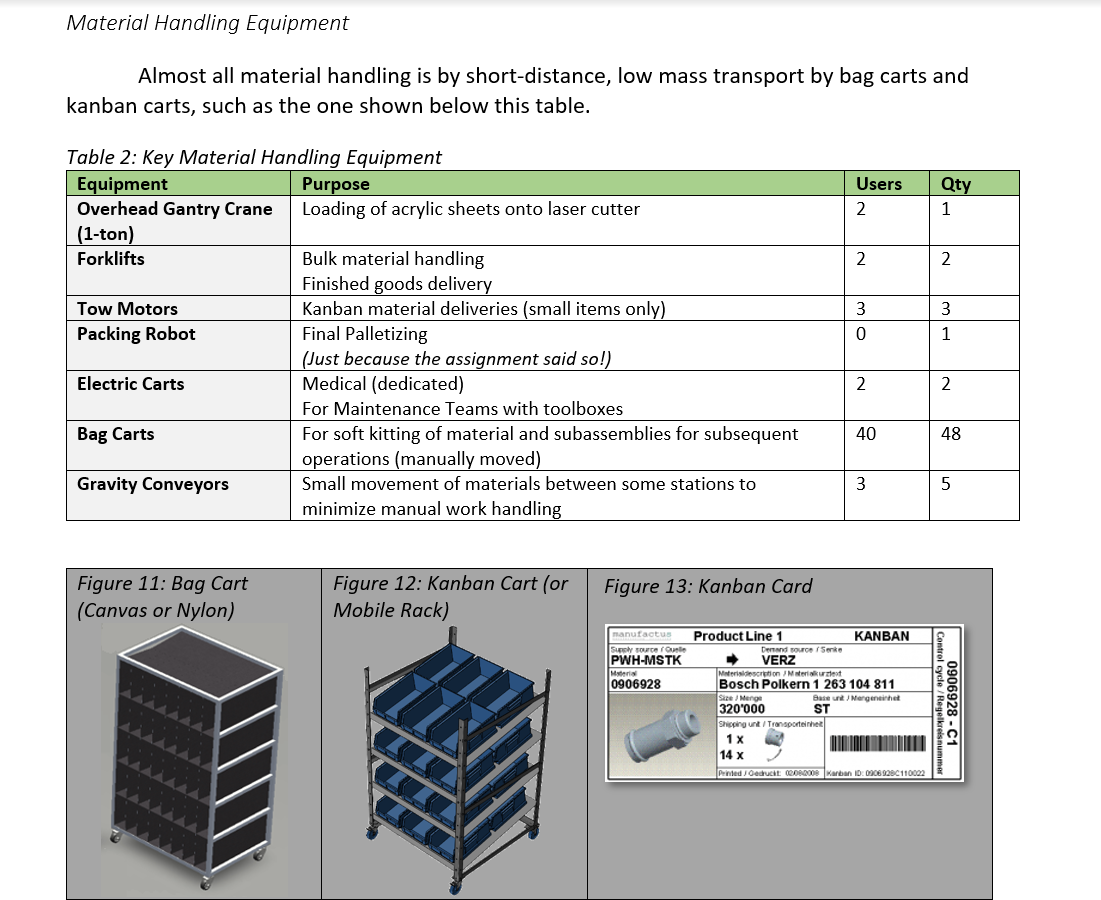

Workstation Design (with Ergonomics) Figure 9: Chassis Assembly Station t" for Completed Items. has canvas-lined pockets to he finished goods as they are the next process. Note: The two carts are on wheels and can be easily moved to the most comfortable positions. Figure 10: Ergonomic Analysis (Similar Station) This image does not show the following important items for lean operations: - Andon Lamp: Indicates cell status, including Kanban material requests. - Kanban Cards: Indicates quantity of parts needed of each type. Material Handling Equipment Almost all material handling is by short-distance, low mass transport by bag carts and kanban carts, such as the one shown below this table. Table 2: Kev Material Handlina Eauibment \begin{tabular}{|l|l|l|} \hline Figure 11: Bag Cart & Figure 12: Kanban Cart (or & Figure 13: Kanban Card \\ (Canvas or Nylon) & Mobile Rack) & \\ \hline \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts