Question: LINEAR PROGRAMMING A factory manufactures shoe racks, dining table and bookshelf each requiring the use of three operations: Cutting, Assembly, and Finishing. The first operation

LINEAR PROGRAMMING

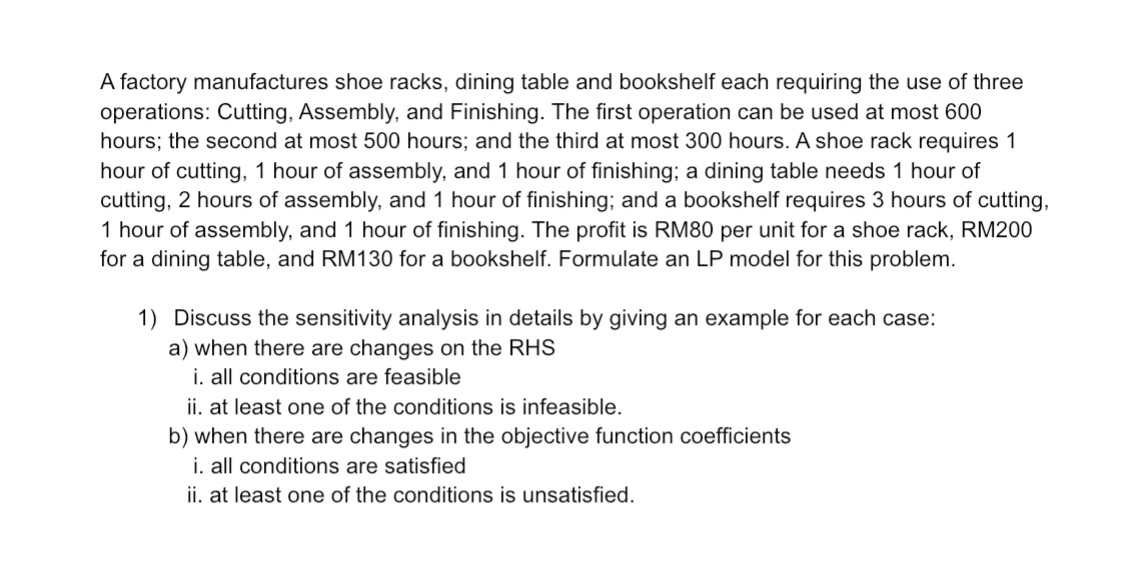

A factory manufactures shoe racks, dining table and bookshelf each requiring the use of three operations: Cutting, Assembly, and Finishing. The first operation can be used at most 600 hours; the second at most 500 hours; and the third at most 300 hours. A shoe rack requires 1 hour of cutting, 1 hour of assembly, and 1 hour of finishing; a dining table needs 1 hour of cutting, 2 hours of assembly, and 1 hour of finishing; and a bookshelf requires 3 hours of cutting, 1 hour of assembly, and 1 hour of finishing. The profit is RM80 per unit for a shoe rack, RM200 for a dining table, and RM130 for a bookshelf. Formulate an LP model for this problem. 1) Discuss the sensitivity analysis in details by giving an example for each case: a) when there are changes on the RHS i. all conditions are feasible ii. at least one of the conditions is infeasible. b) when there are changes in the objective function coefficients i. all conditions are satisfied ii. at least one of the conditions is unsatisfied

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts