Question: Logistics (System) Management-In-Class Exercise: Hu-Friedy Transp. Alt. Simplified Case Scenario from Hu-Friedy - Evaluating Transportation Alternatives Luke Durand, global procurement manager at Hu-Friedy Mfg. Co.,

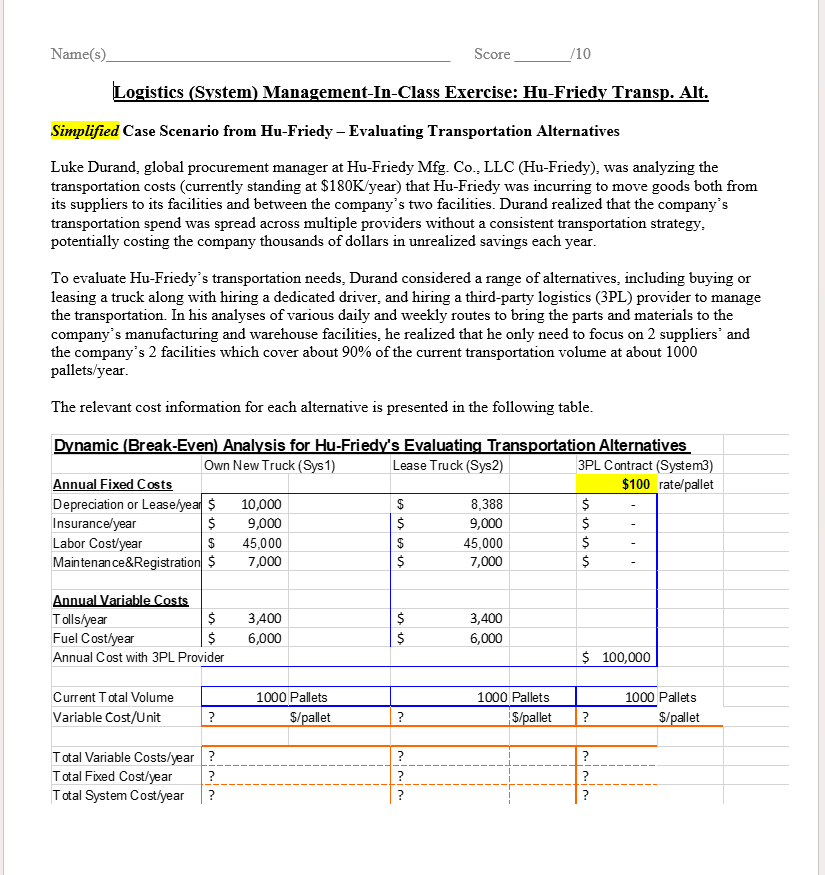

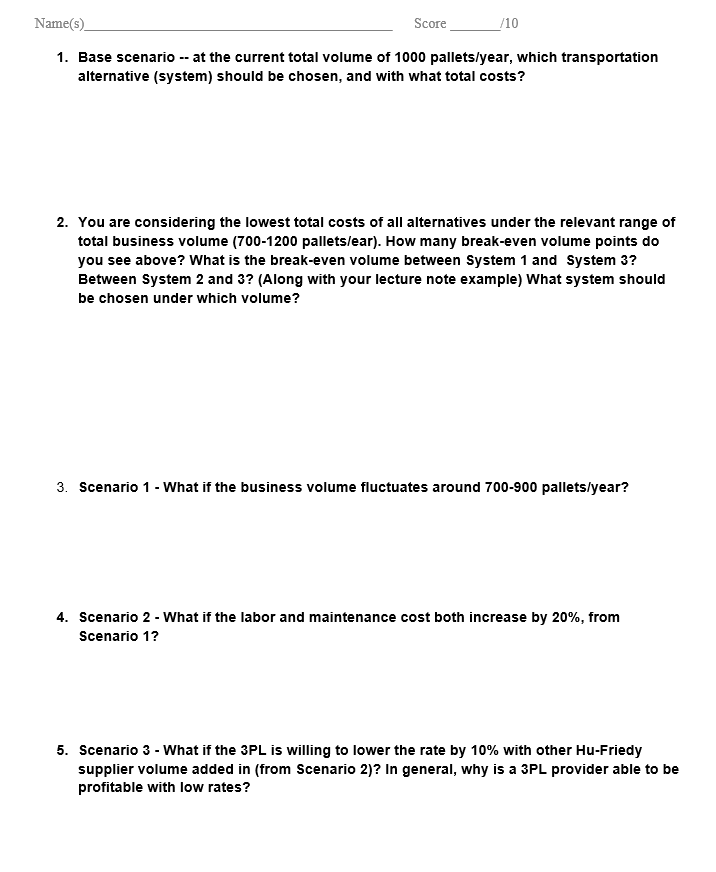

Logistics (System) Management-In-Class Exercise: Hu-Friedy Transp. Alt. Simplified Case Scenario from Hu-Friedy - Evaluating Transportation Alternatives Luke Durand, global procurement manager at Hu-Friedy Mfg. Co., LLC (Hu-Friedy), was analyzing the transportation costs (currently standing at $180K/ year) that Hu-Friedy was incurring to move goods both from its suppliers to its facilities and between the company's two facilities. Durand realized that the company's transportation spend was spread across multiple providers without a consistent transportation strategy, potentially costing the company thousands of dollars in unrealized savings each year. To evaluate Hu-Friedy's transportation needs, Durand considered a range of alternatives, including buying or leasing a truck along with hiring a dedicated driver, and hiring a third-party logistics (3PL) provider to manage the transportation. In his analyses of various daily and weekly routes to bring the parts and materials to the company's manufacturing and warehouse facilities, he realized that he only need to focus on 2 suppliers' and the company's 2 facilities which cover about 90% of the current transportation volume at about 1000 pallets/year. 1. Base scenario -- at the current total volume of 1000 pallets/year, which transportation alternative (system) should be chosen, and with what total costs? 2. You are considering the lowest total costs of all alternatives under the relevant range of total business volume (700-1200 pallets/ear). How many break-even volume points do you see above? What is the break-even volume between System 1 and System 3 ? Between System 2 and 3 ? (Along with your lecture note example) What system should be chosen under which volume? 3. Scenario 1 - What if the business volume fluctuates around 700900 pallets/year? 4. Scenario 2 - What if the labor and maintenance cost both increase by 20%, from Scenario 1? 5. Scenario 3 - What if the 3PL is willing to lower the rate by 10% with other Hu-Friedy supplier volume added in (from Scenario 2)? In general, why is a 3PL provider able to be profitable with low rates

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts