Question: LOOKING FOR ANSWER TO PART C Use the following steps in completing the aggregate production planning problems: 1. Carefully analyze and summarize the information given

LOOKING FOR ANSWER TO PART C

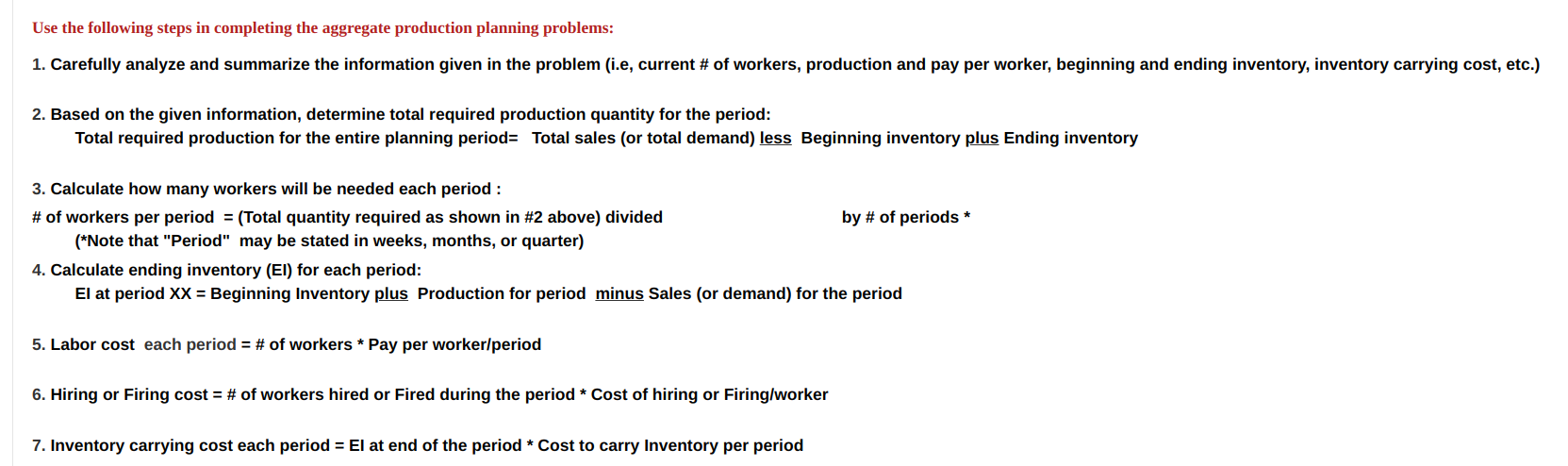

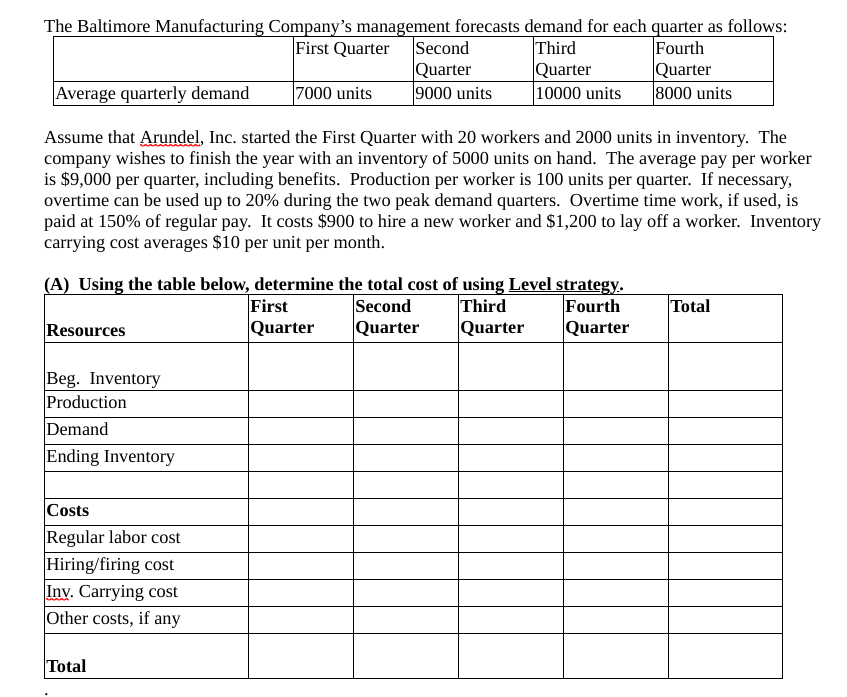

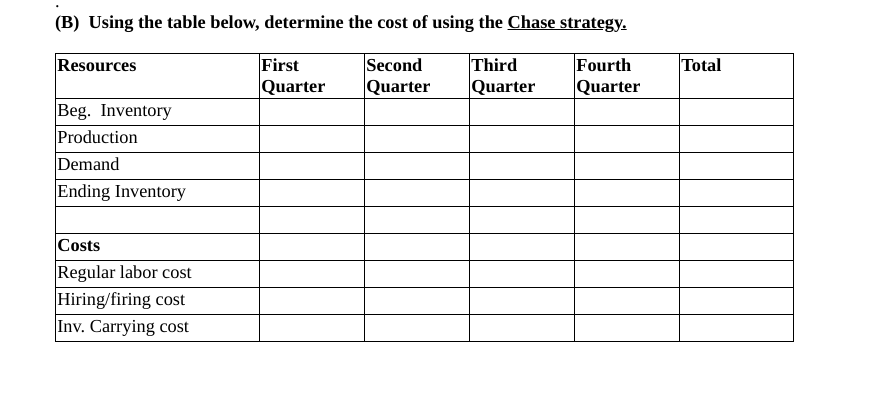

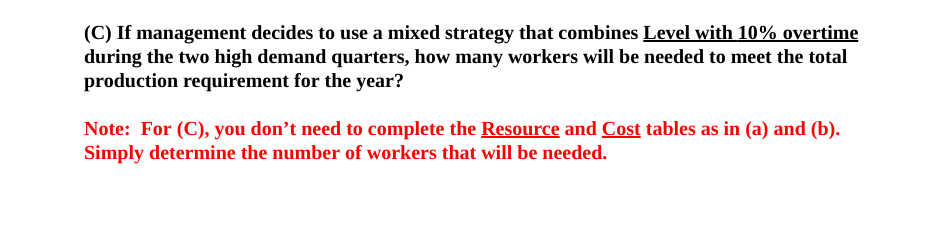

Use the following steps in completing the aggregate production planning problems: 1. Carefully analyze and summarize the information given in the problem (i.e, current # of workers, production and pay per worker, beginning and ending inventory, inventory carrying cost, etc.) 2. Based on the given information, determine total required production quantity for the period: Total required production for the entire planning period= Total sales (or total demand) less Beginning inventory plus Ending inventory 3. Calculate how many workers will be needed each period : # of workers per period = (Total quantity required as shown in #2 above) divided by # of periods * (*Note that "Period" may be stated in weeks, months, or quarter) 4. Calculate ending inventory (EI) for each period: El at period XX = Beginning Inventory plus Production for period minus Sales (or demand) for the period 5. Labor cost each period = # of workers * Pay per worker/period 6. Hiring or Firing cost = # of workers hired or Fired during the period * Cost of hiring or Firing/worker 7. Inventory carrying cost each period = El at end of the period * Cost to carry Inventory per period The Baltimore Manufacturing Company's management forecasts demand for each quarter as follows: First Quarter Second Third Fourth Quarter Quarter Quarter Average quarterly demand 7000 units 9000 units 10000 units 8000 units Assume that Arundel, Inc. started the First Quarter with 20 workers and 2000 units in inventory. The company wishes to finish the year with an inventory of 5000 units on hand. The average pay per worker is $9,000 per quarter, including benefits. Production per worker is 100 units per quarter. If necessary, overtime can be used up to 20% during the two peak demand quarters. Overtime time work, if used, is paid at 150% of regular pay. It costs $900 to hire a new worker and $1,200 to lay off a worker. Inventory carrying cost averages $10 per unit per month. (A) Using the table below, determine the total cost of using Level strategy. First Second Third Fourth Resources Quarter Quarter Quarter Quarter Total Beg. Inventory Production Demand Ending Inventory Costs Regular labor cost Hiring/firing cost Iny. Carrying cost Other costs, if any Total (B) Using the table below, determine the cost of using the Chase strategy. Resources Total First Quarter Second Quarter Third Quarter Fourth Quarter Beg. Inventory Production Demand Ending Inventory Costs Regular labor cost Hiring/firing cost Inv. Carrying cost Other costs, if any Total (C) If management decides to use a mixed strategy that combines Level with 10% overtime during the two high demand quarters, how many workers will be needed to meet the total production requirement for the year? Note: For (C), you don't need to complete the Resource and Cost tables as in (a) and (b). Simply determine the number of workers that will be neededStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock