Question: maintenance course 2 A production machine has a mean time between breakdowns of 3000 hours and a standard deviation of 400 hours. It is assumed

maintenance course

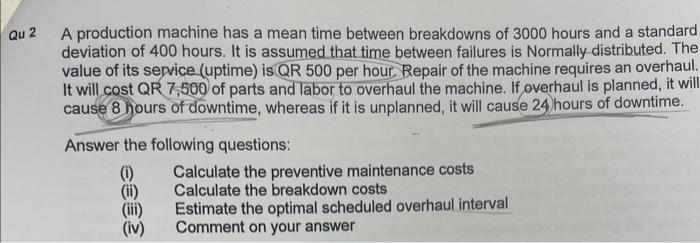

maintenance course2 A production machine has a mean time between breakdowns of 3000 hours and a standard deviation of 400 hours. It is assumed that time between failures is Normally distributed. The value of its sepvice (uptime) is QR 500 per hour. Repair of the machine requires an overhaul It will cost QR7,500 of parts and labor to overhaul the machine. If overhaul is planned, it wil cause 8 hours of downtime, whereas if it is unplanned, it will cause 24 ) hours of downtime. Answer the following questions: (i) Calculate the preventive maintenance costs (ii) Calculate the breakdown costs (iii) Estimate the optimal scheduled overhaul interval (iv) Comment on your

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts