Question: Major Widgets Major Widgets has production at a facility in Memphis and Denver. The Memphis factory can produce up to 150 widgets per day

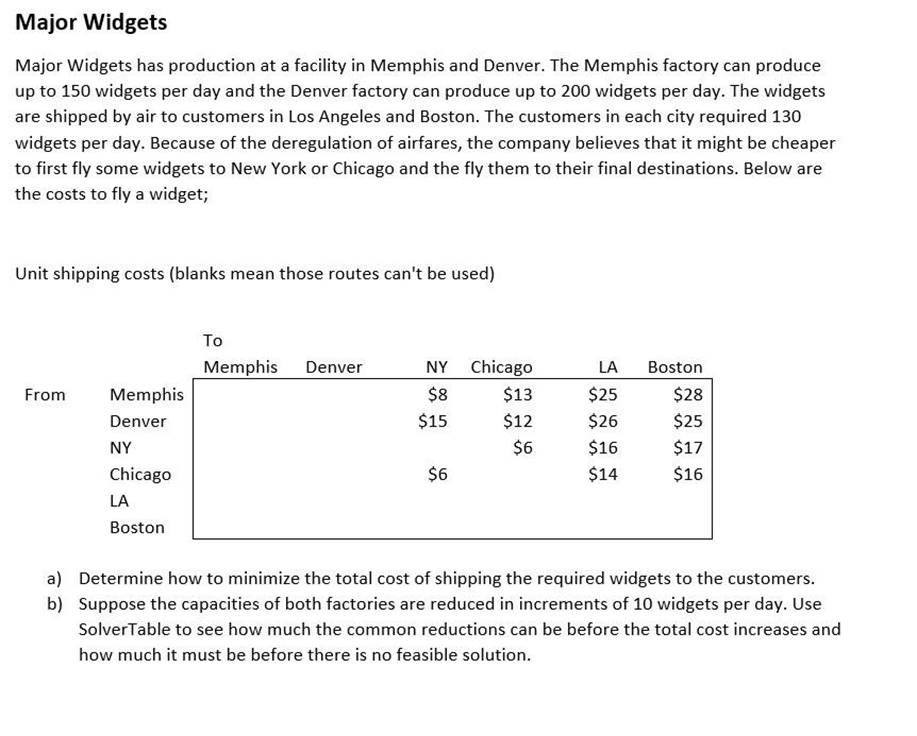

Major Widgets Major Widgets has production at a facility in Memphis and Denver. The Memphis factory can produce up to 150 widgets per day and the Denver factory can produce up to 200 widgets per day. The widgets are shipped by air to customers in Los Angeles and Boston. The customers in each city required 130 widgets per day. Because of the deregulation of airfares, the company believes that it might be cheaper to first fly some widgets to New York or Chicago and the fly them to their final destinations. Below are the costs to fly a widget; Unit shipping costs (blanks mean those routes can't be used) Memphis NY Chicago Denver LA Boston $8 $13 $25 $28 From Memphis Denver $15 $12 $26 $25 $6 $16 $14 NY $17 Chicago $6 $16 LA Boston a) Determine how to minimize the total cost of shipping the required widgets to the customers. b) Suppose the capacities of both factories are reduced in increments of 10 widgets per day. Use SolverTable to see how much the common reductions can be before the total cost increases and how much it must be before there is no feasible solution.

Step by Step Solution

3.56 Rating (160 Votes )

There are 3 Steps involved in it

a Formulation in Excel A G 1 To Shipped NY 100 Chicago 0 LA 5... View full answer

Get step-by-step solutions from verified subject matter experts