Question: Make two recommendations for improvements using a Lean method to solve issues or challenges stated in the case study document. One recommendation should apply the

Make two recommendations for improvements using a Lean method to solve issues or challenges stated in the case study document. One recommendation should apply the 5 Ss or visual workplace, and one recommendation should apply either kanban, poka-yoke, or SMED. Each recommendation should be very specific, including a sketch, step-by-step procedure, revised process map, or other display illustrating the idea. Your detail should be sufficient for Stickley management to make an informed decision whether or not to accept your recommendation. As mentioned in the case, Stickley requires that no additional IT solutions be necessary to implement any of your recommendations. The following parts of the system should be addressed: a. One recommendation to solve a front (before scoping) issue or challenge pay close attention to the statement by James Anderson and other details in the case. b. One recommendation to solve a back (reporting) issue or challenge - pay close attention to the statement by Michelle Cranberry and other details in the case.

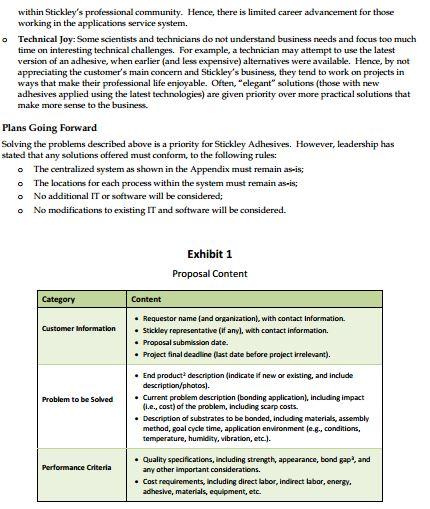

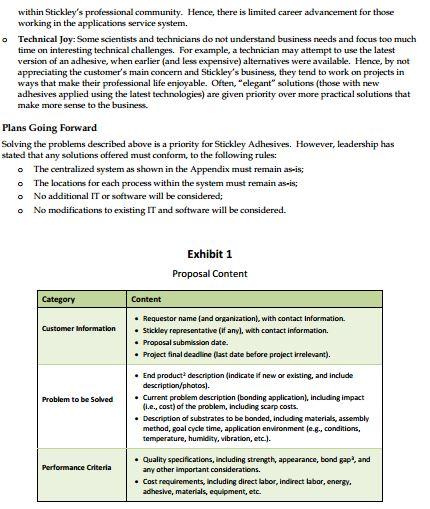

Issues and Challenges After reviewing the surveys and list of mistakes, it was clear that the new system included many "growing pains," and that management under-estimated the challenges in operating a global service system that included significant IT development in an extremely diverse setting. Some of the more significant challenges that remain are discussed below. They are separated into three categories: proposals, communications, and business-related issues. Issues with Proposals: Although the content of each proposal is specified (Exhibit 1) and valuable technical help is provided by sales staff and service engineers, a great deal of variation still exists in the proposals that are submitted to the prioritizing process. An audit indicated that only about 20% of the proposals included all of the information necessary for a thorough analysis. Most proposals lacked one or more types of information. Forty percent lacked detail on the impact of the current problem to the customer. Thirty-five percent of proposals included incorrect information due to the inexperience of the customer making the request. These and other problems necessitated frequent callbacks to requestor and delayed work progress. To begin addressing this problem, James Anderson (global laboratory director) was asked about these problems and was quoted as follows: The applications service system is used for three different purposes. First, it is used by our customers and sometimes by a competitor's customer who is having a problem with an existing adhesive. Second, It is used by our customers who are concerned that a modification to an existing product may affect its adhesion. And, third, it is used by an existing or potential customer who has an idea for a new product requiring an adhesive application. Guidelines for each requestor are provided on the applications service web site (these guidelines are shown in Exhibit 1). The web site includes an online portal where requests are submitted (those entering information can use any format they desire). Staff at the prioritizing process in Puerto Rico use this information to start their work. Today, this activity starts by confirming customer information, verifying accuracy of contact information, logging the details of the request, and determining if the work needs to be done by a scientist or technician. If they have questions or need clarification, they will contact the request directly by e-mail. About 70% are requested by existing customers, and 30% of requests are made by new customers. New customers will often contact a member of the sales team, who will review the request and submit it to the applications service on-line portal. Many new customers contact the Stickley Worldwide call center located in Delhi India), who provide the application service web site information to the caller. For existing customer requests, about half concern troubleshooting and about half concern new or modified designs. Requests for modified designs often concern design changes that potentially affect adhesive bonding. Existing customers will often contact a technical service engineer who will review the request and submit it to the applications service on-line portal. Some existing customers submit their request directly to the applications service on-line portal, while others (who are new to the applications service) may contact the Stickley call center, who provide the application service web site information to the caller. Other details that may be relevant are also provided. They include issues relating to: o Incomplete Information: Many customers and Stickley staff who are inexperienced in the system included irrelevant or incomplete information. One feature of importance is substrates (ie., the portion of the part that makes contact with the adhesive). For example, they did not indicate the surface roughness or substrate flexibility specifications, both of which are key to successful bonding Many customers failed to account for all relevantend-product" (i.e., the final product that includes the bonded parts) information, such as packaging warehousing, or other inventory-storage information o Gaming Requests: Many customers specified deadlines that were much sooner than actually needed. These customers were attempting save money by not paying for expedited service. Also, members of the sales team often requested work on behalf of potential customers even when it was unlikely that this customer would purchase adhesive products from Stickley. Because the service was free of charge, sales staff felt no need to save the company from incurring unnecessary cost in hope that they would receive a potential sales commissions. o Wasted Scientist/Technician Time: The prioritizing process often failed to detect problems with requests. And different prioritizing personal used inconsistent criteria for assigning scientists or technicians. In these cases, the scientist or technician would need to return the request to prioritizing with a note indicated what they thought was wrong. Some scientists and technicians saved time by reaching out to customers or sales force themselves. This was time consuming and usually the corrections were not logged in the system because the prioritizing process never heard about the change. The lack of documentation had effects when future requests from the customer were made, such as incorrect history of prior project technical details. Issues with Comenications Many instances have been noted where communications has proven to be the source of problems. A significant number of problems appear to be rooted in language and cultural differences. For example, a customer in China (native language Mandarin) may be requesting a project that will be prioritized in Puerto Rico (native language Spanish), scoped in the U.S. (native language English), with experiments performed in Bangladesh (native language Bengali), and a final report written in English in the Philippines (native language Filipino). The service system itself spans four time zones, with the all- important scoping process located about 12-hour time difference from a Chinese customer. Some specific problems related to communications are indicated below: o Stickley Call Center: Customers contacting the Stickley call center in India with issues that may require the applications service are not always routed to the applications service. For example, sometimes the call center representative simply tells the caller that they cannot be helped. At other times, callers are instructed to call the application service center, even though there is no way to contact the applications service system by telephone. At other times, customers who need services other than those provided by the applications service are instructed to put a request into the applications service web site portal. It has always been clear that retention and training at the call center is critical to productivity and caller satisfaction. Lately, turnover of employees at the call center has been unusually high. o Final Reports: After the experiments are done and the results analyzed, final reports are written in the Philippines and e-mailed to customers. These reports contain very important information regarding how the adhesive is applied and cured. Although customers have always needed to contact report writers with questions, there has been a 60% increase in the rate of these follow-up questions after the centralized system was implemented. This "back end" issue is exacerbated in the centralized system because report writers in the Philippines need to get many of the questions answered by contacting the analysis process personnel in Wichita, whose time zone is 14 hours behind them. As stated by Michelle Cranberry, who oversees report writing These problems were anticipated, so the implementation included electronic laboratory notebooks, where the notes written by scientists and technicians were directly imported into final reports. Although this effort helped streamline the process in the Philippines, there appears to be a problem with jargon especially regarding terms and phrases that customers do not understand. In fact, many report writers do not fully understand the content of final reports. For example, U.S. staff may use a local idiom, such as when they stated that a project was "dead in the water", meaning it had little hope of succeeding. They also use some American-based expressions. I remember ane instance where the scientists listed instructions on camping a part, indicating that a certain step was not a "hard and fast rule" meaning that it was not entirely necessary. Because we deal with material hardness and curing time, "hard and fast was interpreted as an instruction concerning the materials and clamping time. They also overuse western business slang, such as one project where the report indicated that they needed to "circle back", meaning to start again. This was not unde tood by report writers and customers. Finally, educated scientists tend to use unnecessary complex words that a non-English speaker may be unaware of, such as instructing them to grasp the part instead of a simpler "hold the part" or "pick up the part." Business-Related Issues Choosing and prioritizing projects based on business needs remains a challenge, even after the centralization of the applications service system. It is difficult to precisely define and quantify business impacts. For example, consider working on a project for a potential new customer that currently buys adhesive from a competitor. In the short term, this project may be unwise, but it could create positive goodwill that will lead to the same customer buying Stickley adhesives in the future. Along with issues related to Stickley's business needs, sometimes projects are chosen that would not benefit the customer. For example, there may be less expensive ways to achieve the same result without using an adhesive product. As designed, the applications service would not identify this potential. Other related business related issues are noted below: Loss of authority and control: The technical staff at each regional location feel that they have lost the ability to exercise local discretion, and that local market forces and cultural differences are not taken into account. For example, it appears that the newer Asian market is more price-sensitive than the more established EU market. Regional General Managers agree that they would like more control within the application system's operation. It is also felt that this lack of control has affected their ability to be competitive and address local market conditions. o Limited Career Opportunities: Traditionally, the best jobs at Stickley have been in the research and development (R&D) division. Chemists and chemical engineers are hired to create new adhesive formulations and increase the application of existing formulations. Those holding Master's degrees are typically assigned to be scientists while those with Bachelor's degree have positions as a technician. When the applications service was initiated about 15 years ago, it was staffed by many scientists and technicians who were recommended by R&D managers. Managers used this opportunity to replace underperforming employees. Even though the applications service is now an important element of Stickley's business model its scientists and technicians remain disrespected within Stickley's professional community. Hence, there is limited career advancement for those working in the applications service system. o Technical Joy: Some scientists and technicians do not understand business needs and focus too much time on interesting technical challenges. For example, a technician may attempt to use the latest version of an adhesive, when earlier (and less expensive) alternatives were available. Hence, by not appreciating the customer's main concern and Stickley's business, they tend to work on projects in ways that make their professional life enjoyable. Often, "elegant" solutions (those with new adhesives applied using the latest technologies) are given priority over more practical solutions that make more sense to the business. Plans Going Forward Solving the problems described above is a priority for Stickley Adhesives. However, leadership has stated that any solutions offered must conform to the following rules: The centralized system as shown in the Appendix must remain as-is; The locations for each process within the system must remain as-is; No additional IT or software will be considered; No mdifications to existing IT and software will be considered. Exhibit 1 Proposal Content Category Content Customer information Requestor name (and organization with contact Information. Stickley representative (if any), with contact information. Proposal submission date. Project final deadline (last date before project irrelevant). Problem to be solved End product description (Indicate if new or existing, and include description/photos) . Current problem description (bonding application, including impact (1.e., cost) of the problem, including scarp costs. Description of substrates to be bonded, including materials, assembly method, goal cycle time, application environment le.g., conditions, temperature, humidity, vibration, etc.). Performance Criteria Quality specifications, including strength, appearance, bond gap, and any other important considerations. Cost requirements, including direct labor, indirect labor, energy. adhesive, materials, equipment, etc