Question: Manufacturing Facility 2 - Improved Enginecring has applied 6 Sigma and Lean Manufacturing techniques and has been able to reduce the setup time on Machine

Manufacturing Facility Improved

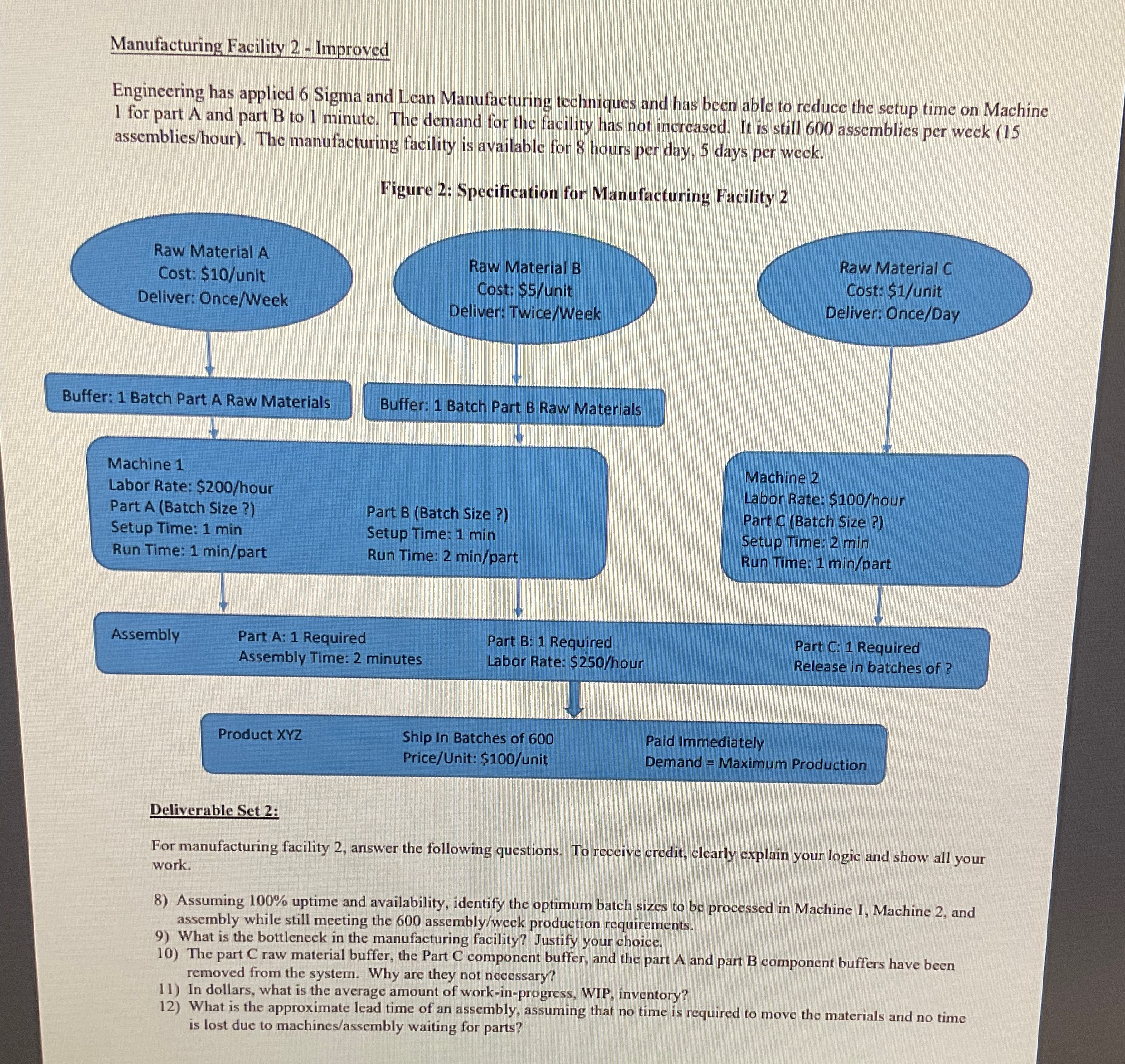

Enginecring has applied Sigma and Lean Manufacturing techniques and has been able to reduce the setup time on Machine for part A and part B to minute. The demand for the facility has not increased. It is still assemblies per week assemblieshour The manufacturing facility is available for hours per day, days per weck.

Figure : Specification for Manufacturing Facility

Raw Material A

Cost: $ unit

Deliver: OnceWeek

Buffer: Batch Part A Raw Materials

Machine

Labor Rate: $ hour

Part A Batch Size

Setup Time: min

Run Time: part

Part A: Required

Assembly Time: minutes

Part B: Required

Labor Rate: $ hour

Part C: Required Release in batches of

Product

Ship In Batches of

Paid Immediately

PriceUnit: $ unit

Demand Maximum Production

Deliverable Set :

For manufacturing facility answer the following questions. To reccive credit, clearly explain your logic and show all your work.

Assuming uptime and availability, identify the optimum batch sizes to be processed in Machine Machine and assembly while still meeting the assemblyweek production requirements.

What is the bottleneck in the manufacturing facility? Justify your choice.

The part raw material buffer, the Part component buffer, and the part A and part component buffers have been removed from the system. Why are they not necessary?

In dollars, what is the average amount of workinprogress, WIP, inventory?

What is the approximate lead time of an assembly, assuming that no time is required to move the materials and no time is lost due to machinesassembly waiting for parts?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock