Question: Manufacturing systems and Design A junior Industrial Engineer has been assigned to improve the operational efficiency of a job shop. The job shop produces ten

Manufacturing systems and Design

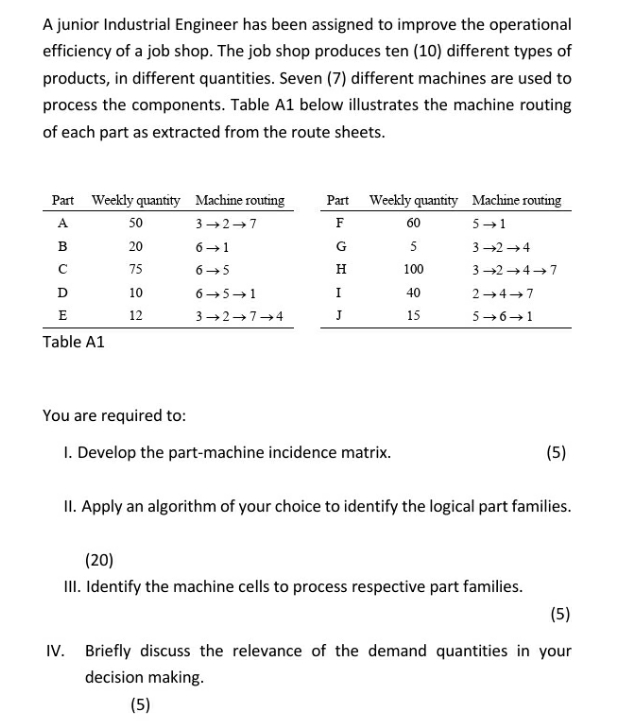

A junior Industrial Engineer has been assigned to improve the operational efficiency of a job shop. The job shop produces ten (10) different types of products, in different quantities. Seven (7) different machines are used to process the components. Table Al below illustrates the machine routing of each part as extracted from the route sheets. Part Weekly quantity Machine routing Part Weekly quantity Machine routing A 50 3-2-7 F 60 5-1 B 20 6 - 1 G 5 3-2-4 C 75 6-5 H 100 3-2-4-7 D 10 6-5-1 H 40 2-4-7 12 3-2-7-4 15 5-6-1 Table A1 You are required to: 1. Develop the part-machine incidence matrix. (5) Il. Apply an algorithm of your choice to identify the logical part families. (20) Ill. Identify the machine cells to process respective part families. (5) IV. Briefly discuss the relevance of the demand quantities in your decision making.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts