Question: Mark would like to make a beam by attaching it to pieces of pine pressure-treated wood and steel portions, as shown below, with 5/8

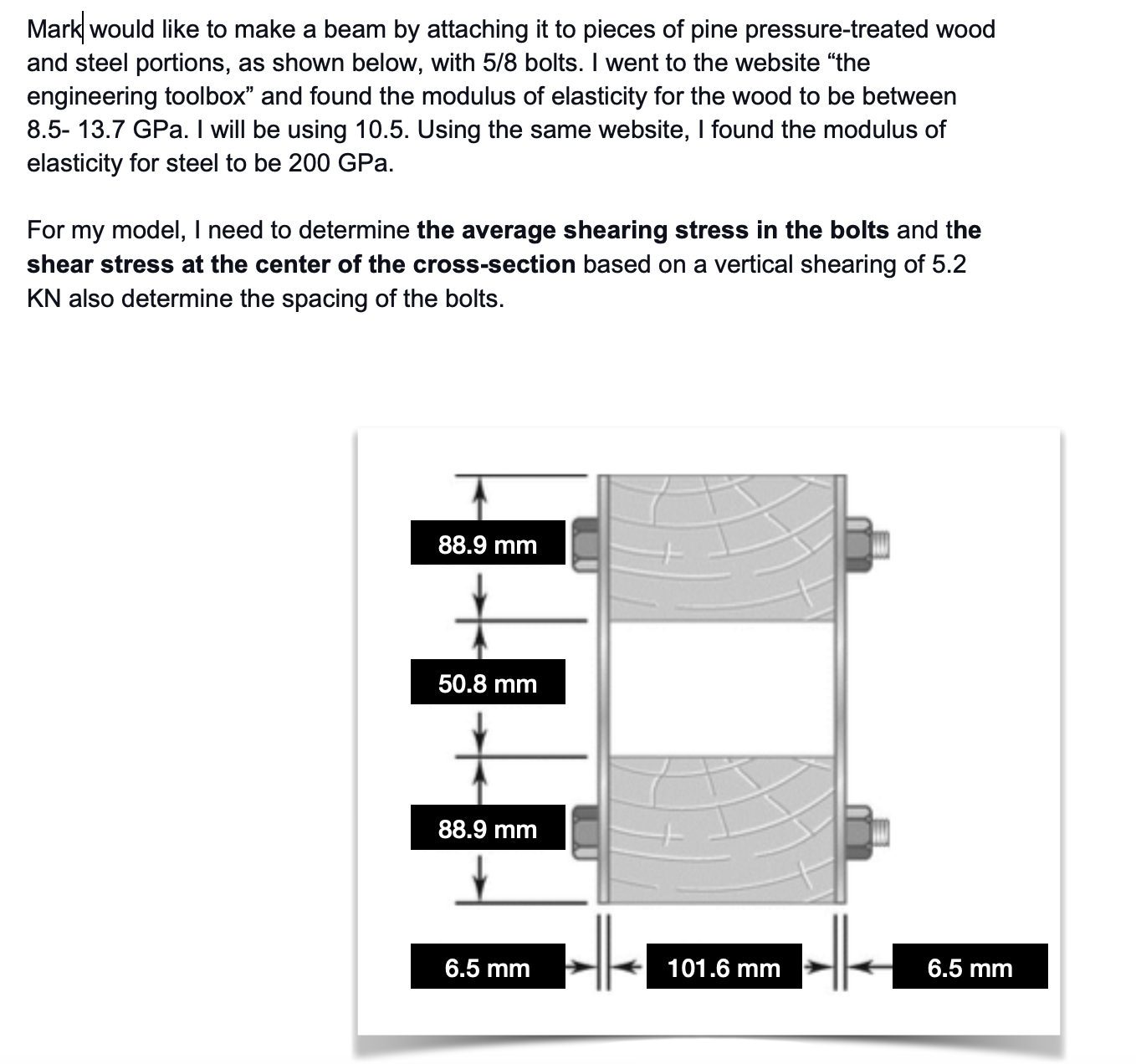

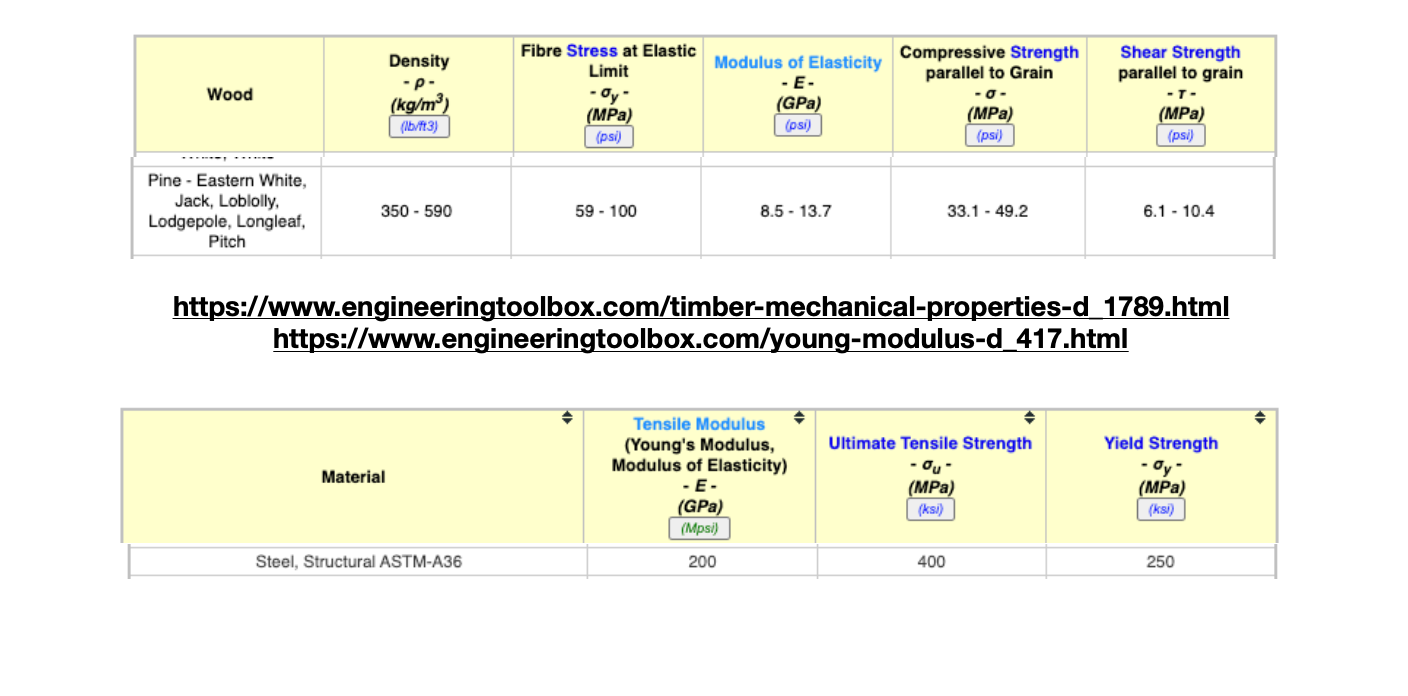

Mark would like to make a beam by attaching it to pieces of pine pressure-treated wood and steel portions, as shown below, with 5/8 bolts. I went to the website "the engineering toolbox" and found the modulus of elasticity for the wood to be between 8.5-13.7 GPa. I will be using 10.5. Using the same website, I found the modulus of elasticity for steel to be 200 GPa. For my model, I need to determine the average shearing stress in the bolts and the shear stress at the center of the cross-section based on a vertical shearing of 5.2 KN also determine the spacing of the bolts. 88.9 mm 50.8 mm 88.9 mm 6.5 mm 101.6 mm 6.5 mm Fibre Stress at Elastic Density Limit Modulus of Elasticity - E- -Oy- (MPa) (GPa) (psi) (psi) Wood Pine - Eastern White, Jack, Loblolly, Lodgepole, Longleaf, Pitch -P- (kg/m) (lb/ft3) Compressive Strength parallel to Grain -0- (MPa) (psi) Shear Strength parallel to grain -7- (MPa) (psi) 350-590 59-100 8.5-13.7 33.1-49.2 6.1-10.4 https://www.engineeringtoolbox.com/timber-mechanical-properties-d 1789.html https://www.engineeringtoolbox.com/young-modulus-d_417.html Material Steel, Structural ASTM-A36 Tensile Modulus (Young's Modulus, Modulus of Elasticity) - E- (GPa) Ultimate Tensile Strength Yield Strength -Ou- (MPa) (ksi) -Oy- (MPa) (ksi) (Mpsi) 200 400 250

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts