Question: ME 3 2 3 MACHINE DESIGN I HOMEWORK 1 - For the bolted assembly, two plates of cast iron are clamped together. The top plate

ME MACHINE DESIGN I

HOMEWORK

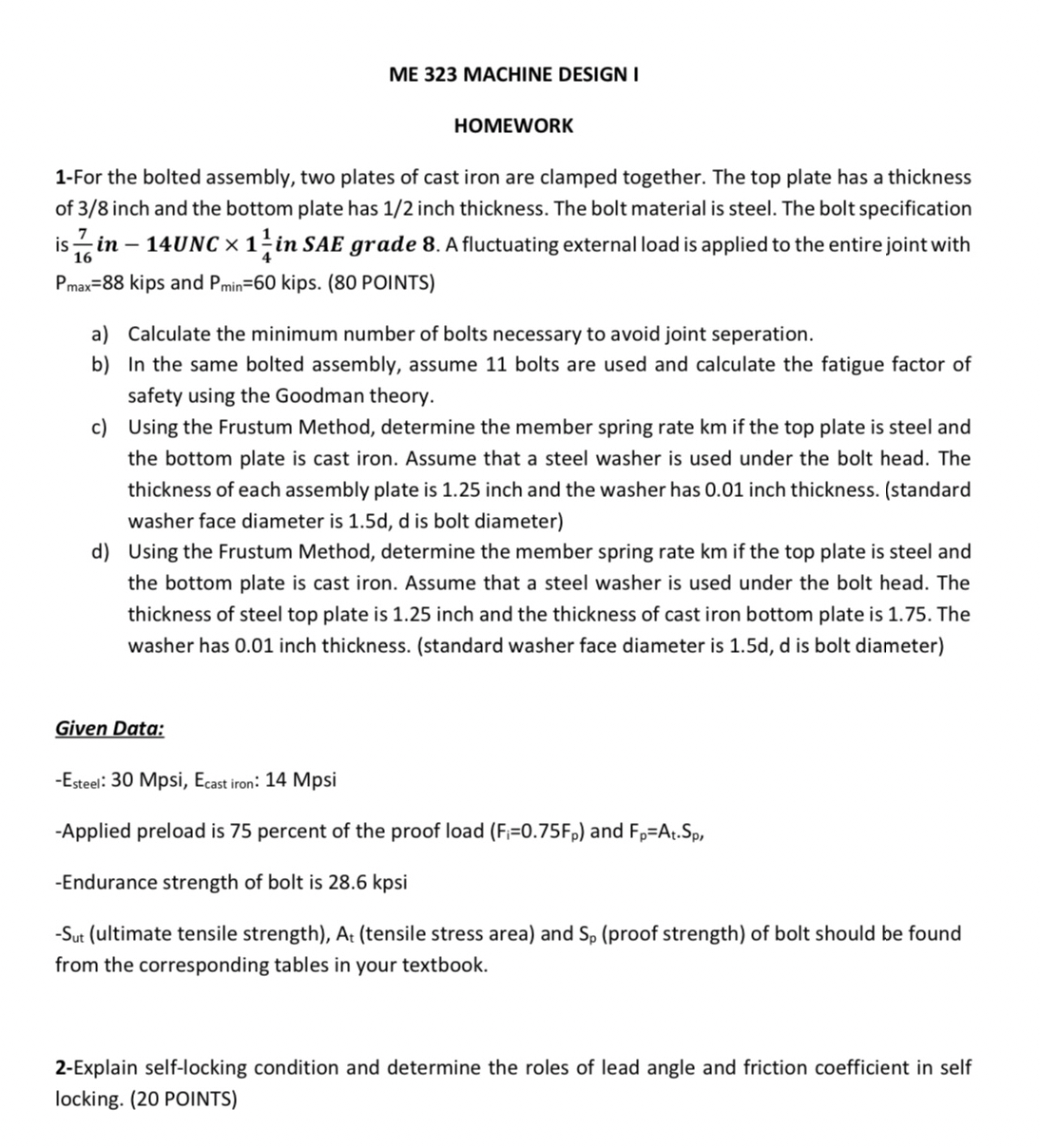

For the bolted assembly, two plates of cast iron are clamped together. The top plate has a thickness of inch and the bottom plate has inch thickness. The bolt material is steel. The bolt specification is UNCinSAE grade A fluctuating external load is applied to the entire joint with kips and kips. POINTS

a Calculate the minimum number of bolts necessary to avoid joint seperation.

b In the same bolted assembly, assume bolts are used and calculate the fatigue factor of safety using the Goodman theory.

c Using the Frustum Method, determine the member spring rate km if the top plate is steel and the bottom plate is cast iron. Assume that a steel washer is used under the bolt head. The thickness of each assembly plate is inch and the washer has inch thickness. standard washer face diameter is d d is bolt diameter

d Using the Frustum Method, determine the member spring rate km if the top plate is steel and the bottom plate is cast iron. Assume that a steel washer is used under the bolt head. The thickness of steel top plate is inch and the thickness of cast iron bottom plate is The washer has inch thickness. standard washer face diameter is is bolt diameter

Given Data:

::

Applied preload is percent of the proof load

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock