Question: Methane mass flow rate, m o H C H , 2 ( k g ? day ) , and C O 2 mass flow rate,

Methane mass flow rate, day and mass flow rate, day

Previously, waste sludges from the MCUP plant's multiple wastewater treatment process trains were dewatered and trucked to an offsite landfill. However, in a major environmentally sustainable expansion at MCUP's wastewater treatment plant, the various sludge streams from the MCUP # process and many others are fed to anaerobic biochemical reactorscommonly called anaerobic digestersat a rate of day producing three residuals:

i Digester gas composed of percent methane by volume and percent by volume with a pressure of atm and a temperature of

ii Biologically stable humuslike solid material called digested sludge percent by mass of the raw sludge.

iii. Liquid supernatant percent by mass of the raw sludge.

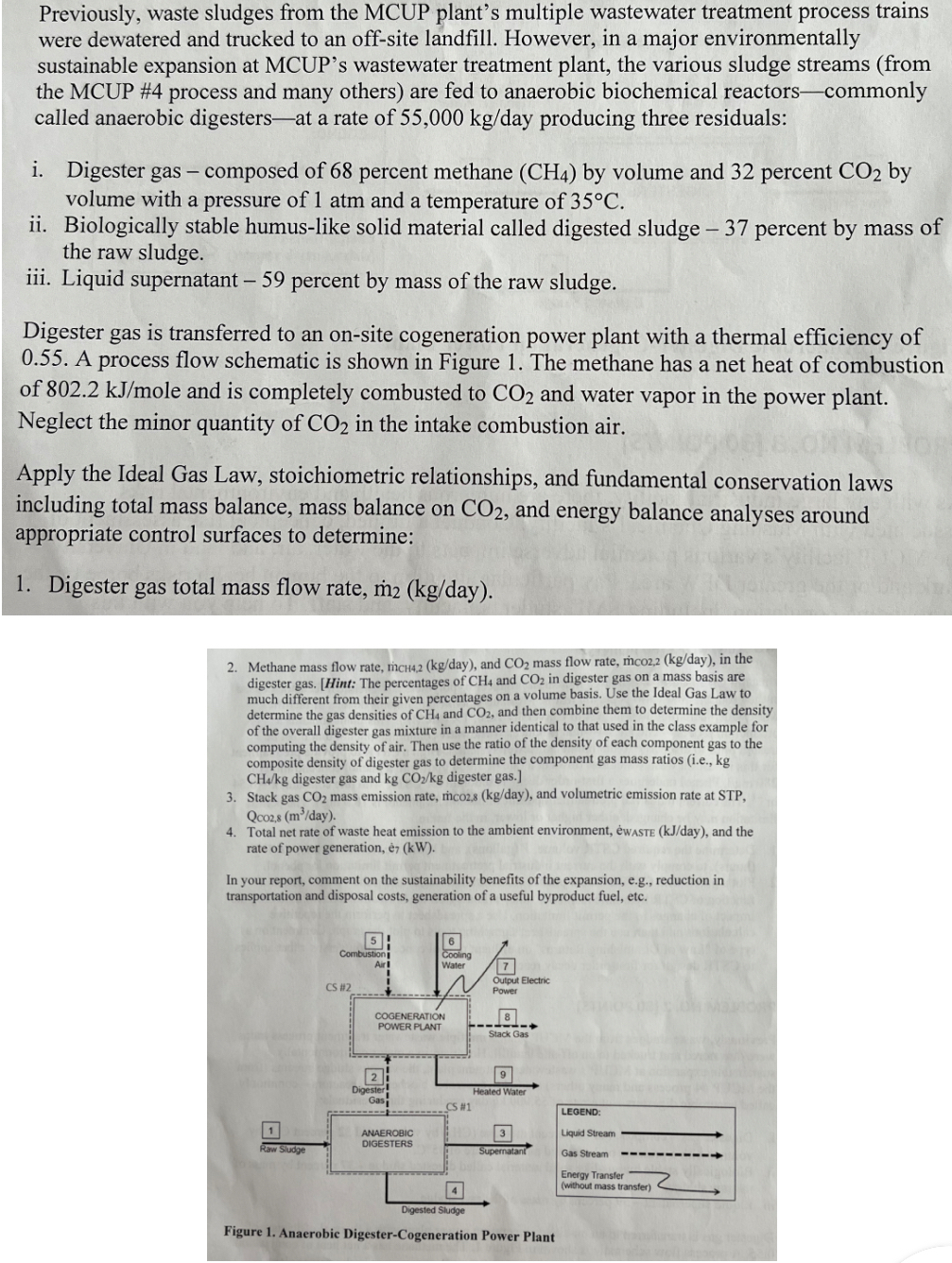

Digester gas is transferred to an onsite cogeneration power plant with a thermal efficiency of A process flow schematic is shown in Figure The methane has a net heat of combustion of ole and is completely combusted to and water vapor in the power plant. Neglect the minor quantity of in the intake combustion air.

Apply the Ideal Gas Law, stoichiometric relationships, and fundamental conservation laws including total mass balance, mass balance on and energy balance analyses around appropriate control surfaces to determine:

Digester gas total mass flow rate, day

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock