Question: MGMT339 Assignment 5 - Chapters K 3,K6, & K7 (Show your work to receive credit) 1. (a) Name and explain major cost categories identified by

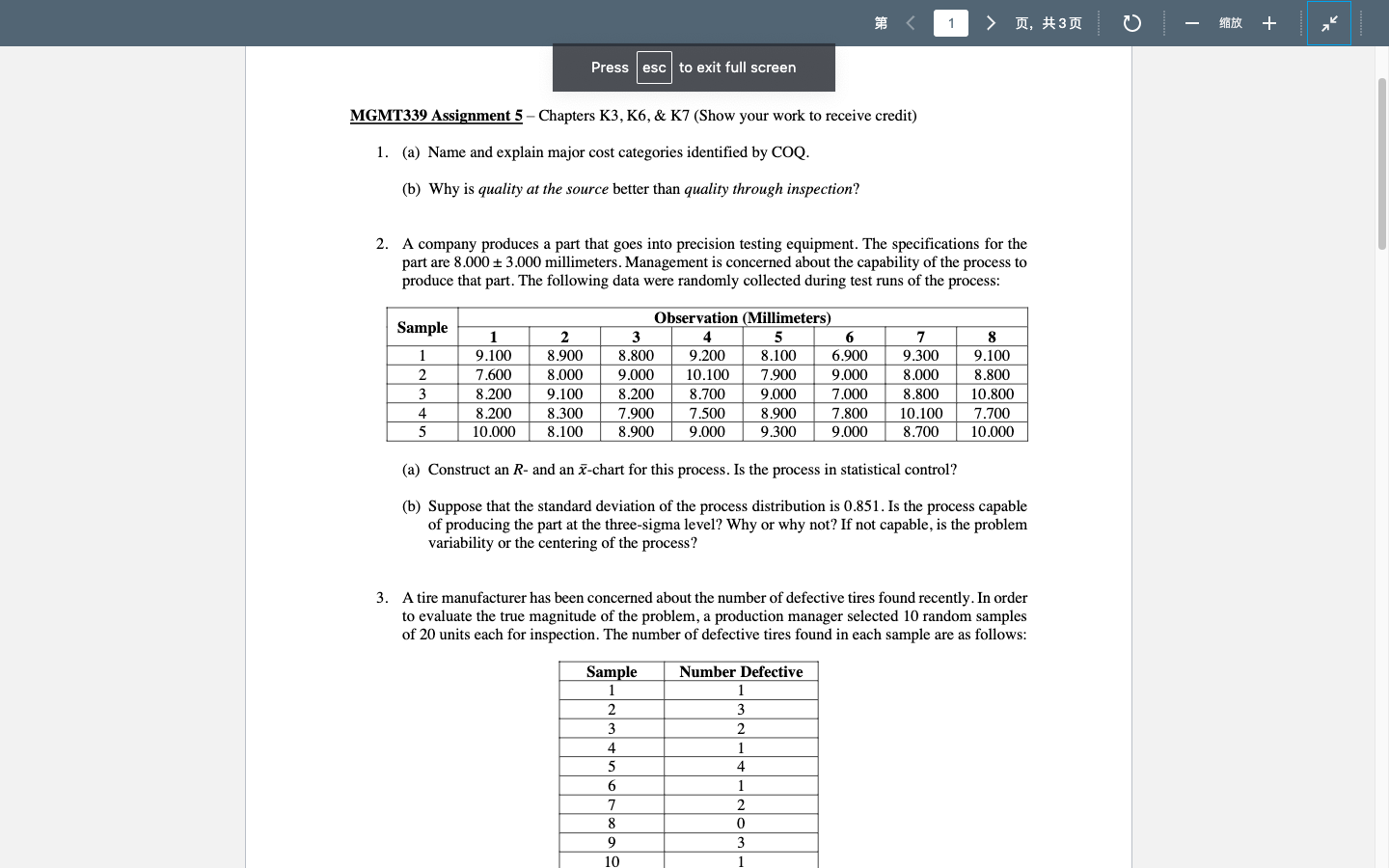

MGMT339 Assignment 5 - Chapters K 3,K6, \& K7 (Show your work to receive credit) 1. (a) Name and explain major cost categories identified by COQ. (b) Why is quality at the source better than quality through inspection? 2. A company produces a part that goes into precision testing equipment. The specifications for the part are 8.0003.000 millimeters. Management is concerned about the capability of the process to produce that part. The following data were randomly collected during test runs of the process: (a) Construct an R - and an x-chart for this process. Is the process in statistical control? (b) Suppose that the standard deviation of the process distribution is 0.851 . Is the process capable of producing the part at the three-sigma level? Why or why not? If not capable, is the problem variability or the centering of the process? 3. A tire manufacturer has been concerned about the number of defective tires found recently. In order to evaluate the true magnitude of the problem, a production manager selected 10 random samples of 20 units each for inspection. The number of defective tires found in each sample are as follows: MGMT339 Assignment 5 - Chapters K 3,K6, \& K7 (Show your work to receive credit) 1. (a) Name and explain major cost categories identified by COQ. (b) Why is quality at the source better than quality through inspection? 2. A company produces a part that goes into precision testing equipment. The specifications for the part are 8.0003.000 millimeters. Management is concerned about the capability of the process to produce that part. The following data were randomly collected during test runs of the process: (a) Construct an R - and an x-chart for this process. Is the process in statistical control? (b) Suppose that the standard deviation of the process distribution is 0.851 . Is the process capable of producing the part at the three-sigma level? Why or why not? If not capable, is the problem variability or the centering of the process? 3. A tire manufacturer has been concerned about the number of defective tires found recently. In order to evaluate the true magnitude of the problem, a production manager selected 10 random samples of 20 units each for inspection. The number of defective tires found in each sample are as follows

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts