Question: MUST COMPLETE THE TABLE BELOW WITH THE INFORMATION GIVEN HERE. PLEASE DO NOT ATTEMPT TO DO ANYTHING BUT SOLVE THE TABLE. THANK YOU. For this

MUST COMPLETE THE TABLE BELOW WITH THE INFORMATION GIVEN HERE. PLEASE DO NOT ATTEMPT TO DO ANYTHING BUT SOLVE THE TABLE. THANK YOU.

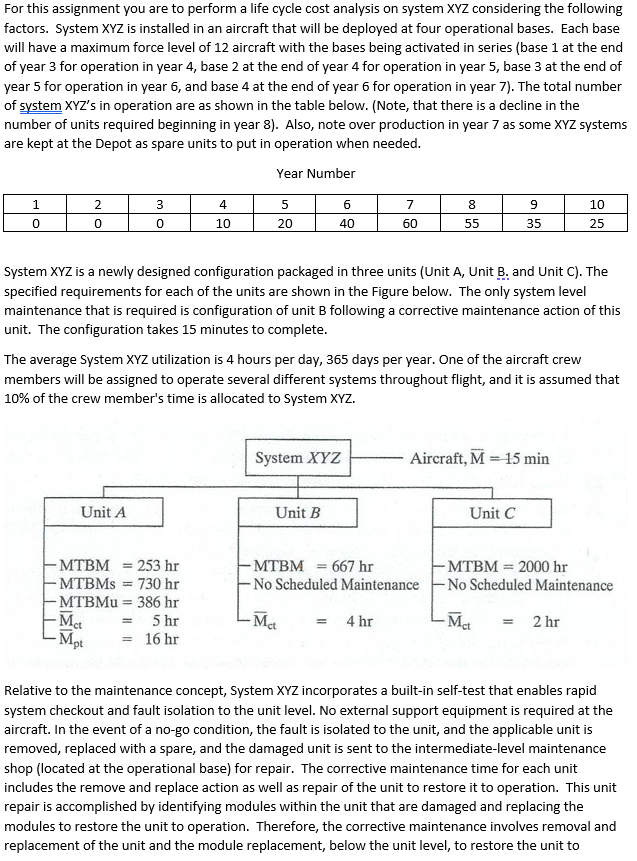

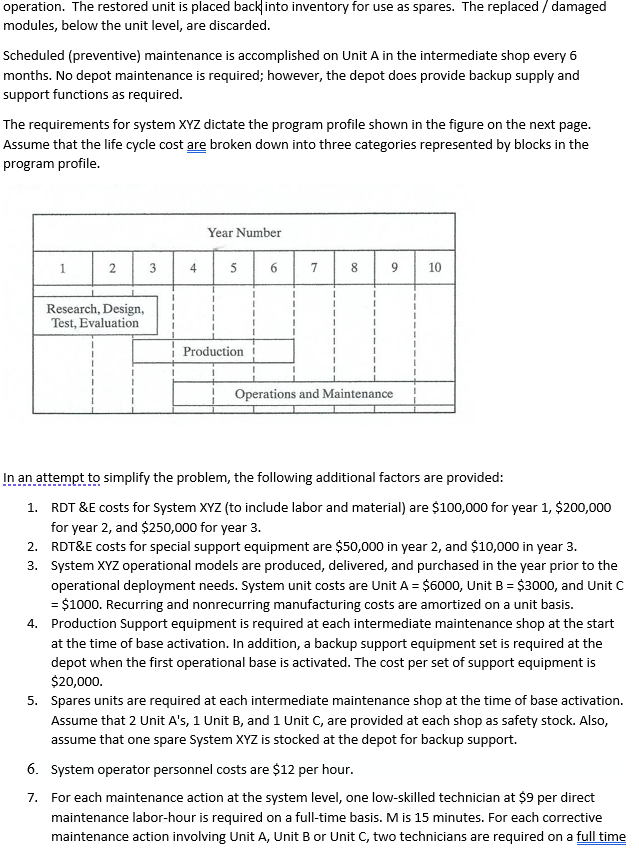

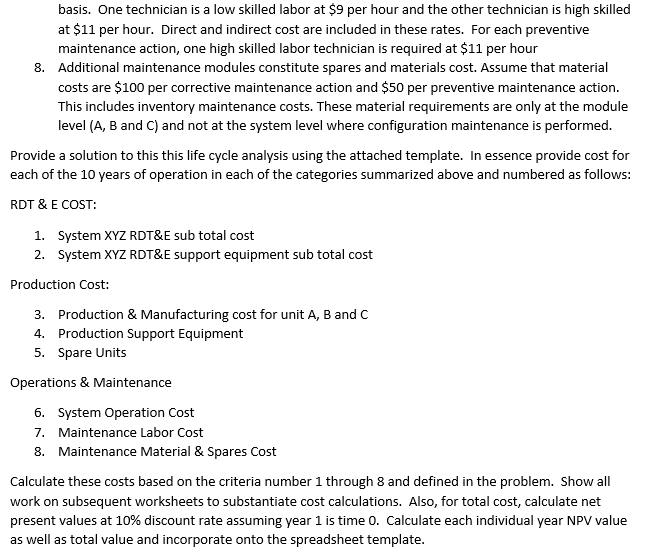

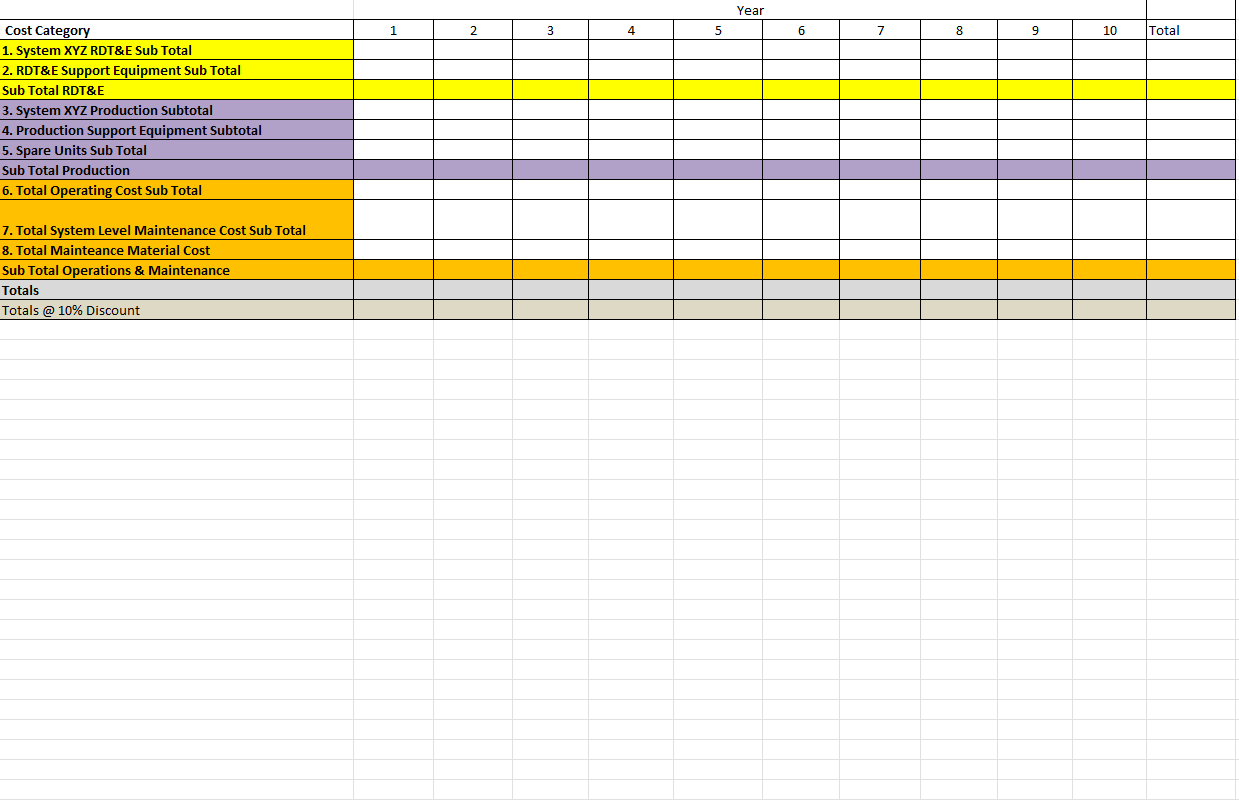

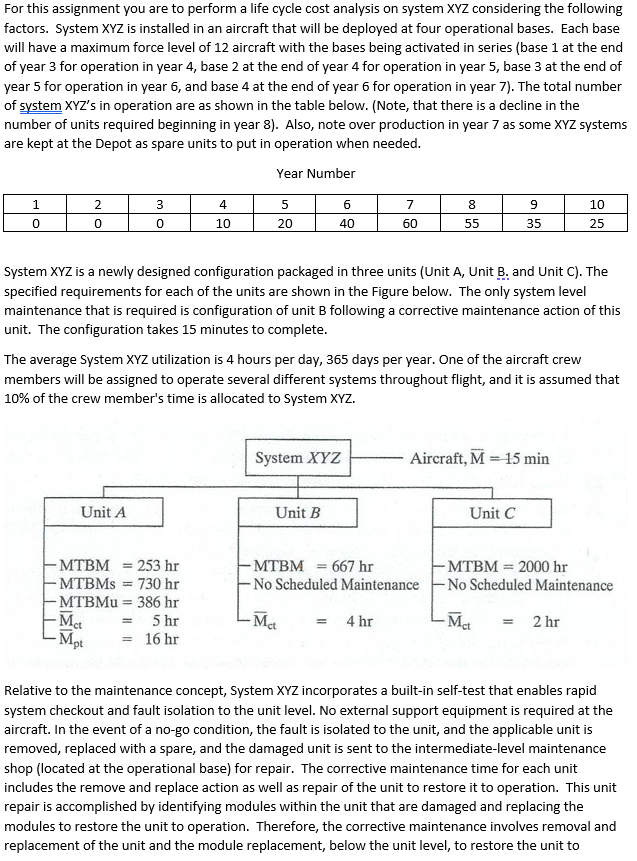

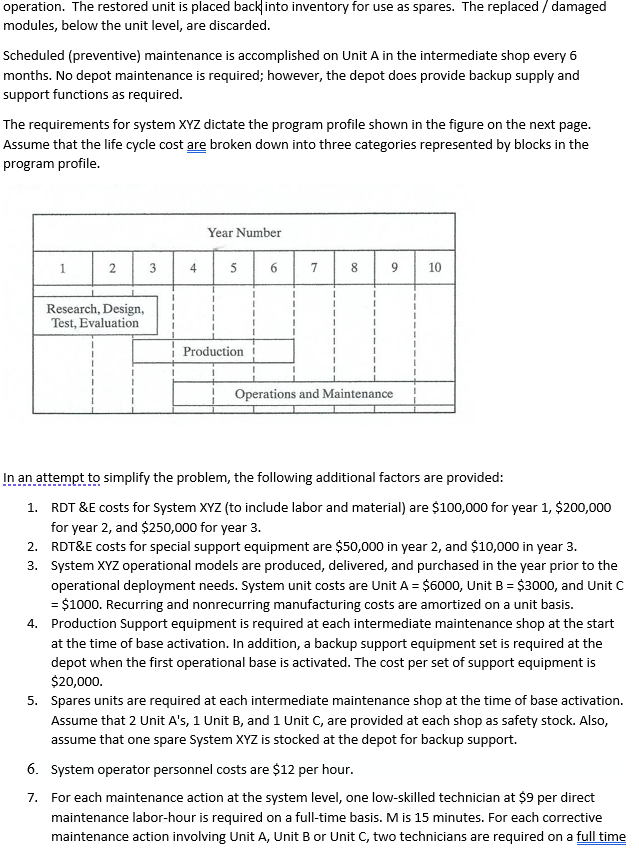

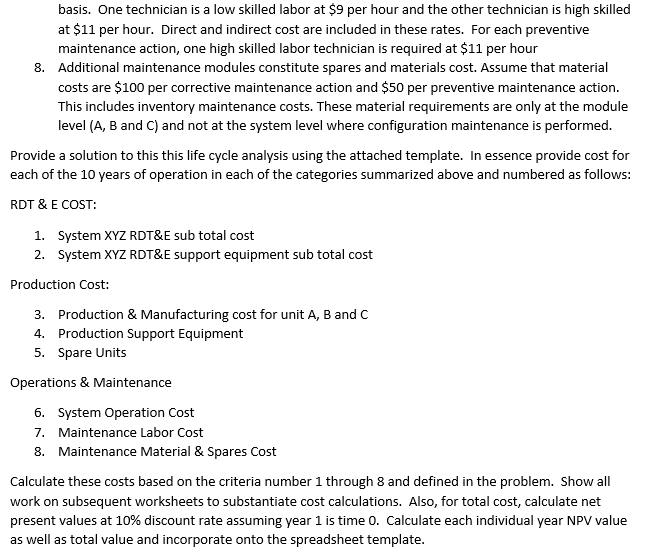

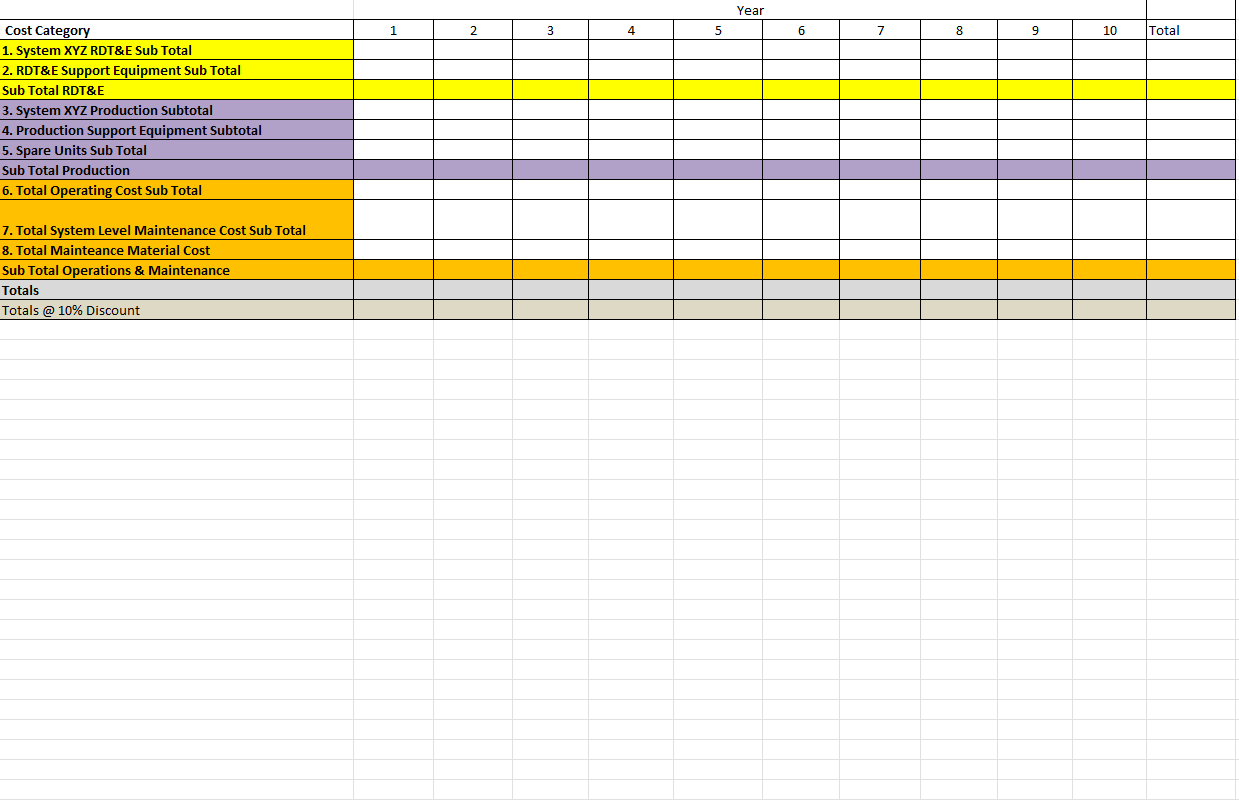

For this assignment you are to perform a life cycle cost analysis on system XYZ considering the following factors. System XYZ is installed in an aircraft that will be deployed at four operational bases. Each base will have a maximum force level of 12 aircraft with the bases being activated in series (base 1 at the end of year 3 for operation in year 4, base 2 at the end of year 4 for operation in year 5, base 3 at the end of year 5 for operation in year 6, and base 4 at the end of year 6 for operation in year 7). The total number of system XYZ's in operation are as shown in the table below. (Note, that there is a decline in the number of units required beginning in year 8). Also, note over production in year 7 as some XYZ systems are kept at the Depot as spare units to put in operation when needed. Year Number 1 2 3 4 5 9 10 6 40 7 60 8 55 0 0 0 10 20 35 25 System XYZ is a newly designed configuration packaged in three units (Unit A, Unit B. and Unit C). The specified requirements for each of the units are shown in the Figure below. The only system level maintenance that is required is configuration of unit B following a corrective maintenance action of this unit. The configuration takes 15 minutes to complete. The average System XYZ utilization is 4 hours per day, 365 days per year. One of the aircraft crew members will be assigned to operate several different systems throughout flight, and it is assumed that 10% of the crew member's time is allocated to System XYZ. System XYZ Aircraft, M = 15 min Unit A Unit B Unit C -MTBM = 667 hr - No Scheduled Maintenance -MTBM = 2000 hr -No Scheduled Maintenance -MTBM = 253 hr -MTBMs = 730 hr -MTBMu = 386 hr 5 hr - Mat = 16 hr -Ma -Mct = 4hr Mc = 2 hr Relative to the maintenance concept, System XYZ incorporates a built-in self-test that enables rapid system checkout and fault isolation to the unit level. No external support equipment is required at the aircraft. In the event of a no-go condition, the fault is isolated to the unit, and the applicable unit is removed, replaced with a spare, and the damaged unit is sent to the intermediate-level maintenance shop (located at the operational base) for repair. The corrective maintenance time for each unit includes the remove and replace action as well as repair of the unit to restore it to operation. This unit repair is accomplished by identifying modules within the unit that are damaged and replacing the modules to restore the unit to operation. Therefore, the corrective maintenance involves removal and replacement of the unit and the module replacement, below the unit level, to restore the unit to operation. The restored unit is placed back into inventory for use as spares. The replaced / damaged modules, below the unit level, are discarded. Scheduled (preventive) maintenance is accomplished on Unit A in the intermediate shop every 6 months. No depot maintenance is required; however, the depot does provide backup supply and support functions as required. The requirements for system XYZ dictate the program profile shown in the figure on the next page. Assume that the life cycle cost are broken down into three categories represented by blocks in the program profile. Year Number 1 2 3 3 4 5 5 6 7 7 8 9 10 Research, Design, Test, Evaluation Production Operations and Maintenance In an attempt to simplify the problem, the following additional factors are provided: 1. RDT &E costs for System XYZ (to include labor and material) are $100,000 for year 1, $200,000 for year 2, and $250,000 for year 3. 2. RDT&E costs for special support equipment are $50,000 in year 2, and $10,000 in year 3. 3. System XYZ operational models are produced, delivered, and purchased in the year prior to the operational deployment needs. System unit costs are Unit A = $6000, Unit B = $3000, and Unit C = $1000. Recurring and nonrecurring manufacturing costs are amortized on a unit basis. 4. Production Support equipment is required at each intermediate maintenance shop at the start at the time of base activation. In addition, a backup support equipment set is required at the a depot when the first operational base is activated. The cost per set of support equipment is $20,000. 5. Spares units are required at each intermediate maintenance shop at the time of base activation. Assume that 2 Unit A's, 1 Unit B, and 1 Unit C, are provided at each shop as safety stock. Also, assume that one spare System XYZ is stocked at the depot for backup support. 6. System operator personnel costs are $12 per hour. 7. For each maintenance action at the system level, one low-skilled technician at $9 per direct maintenance labor-hour is required on a full-time basis. M is 15 minutes. For each corrective maintenance action involving Unit A, Unit B or Unit C, two technicians are required on a full time basis. One technician is a low skilled labor at $9 per hour and the other technician is high skilled at $11 per hour. Direct and indirect cost are included in these rates. For each preventive maintenance action, one high skilled labor technician is required at $11 per hour 8. Additional maintenance modules constitute spares and materials cost. Assume that material costs are $100 per corrective maintenance action and $50 per preventive maintenance action. This includes inventory maintenance costs. These material requirements are only at the module level (A, B and C) and not at the system level where configuration maintenance is performed. Provide a solution to this this life cycle analysis using the attached template. In essence provide cost for each of the 10 years of operation in each of the categories summarized above and numbered as follows: RDT & E COST: 1. System XYZ RDT&E sub total cost 2. System XYZ RDT&E support equipment sub total cost Production Cost: 3. Production & Manufacturing cost for unit A, B and C 4. Production Support Equipment 5. Spare Units Operations & Maintenance 6. System Operation Cost 7. Maintenance Labor Cost 8. Maintenance Material & Spares Cost Calculate these costs based on the criteria number 1 through 8 and defined in the problem. Show all work on subsequent worksheets to substantiate cost calculations. Also, for total cost, calculate net present values at 10% discount rate assuming year 1 is time 0. Calculate each individual year NPV value as well as total value and incorporate onto the spreadsheet template. Year 1 2 3 4 5 6 7 8 9 10 Total Cost Category 1. System XYZ RDT&E Sub Total 2. RDT&E Support Equipment Sub Total Sub Total RDT&E 3. System XYZ Production Subtotal 4. Production Support Equipment Subtotal 5. Spare Units Sub Total Sub Total Production 6. Total Operating Cost Sub Total 7. Total System Level Maintenance Cost Sub Total 8. Total Mainteance Material Cost Sub Total Operations & Maintenance Totals Totals @ 10% Discount