Question: N AaBb CcDdi AaBbCcDdEe ABCcDdEe Aal Heading 3 Normal No Spacing BUS 552 Fall 2020 Homework Assignment S: Linear Programming Due by 11:00 PM (PT)

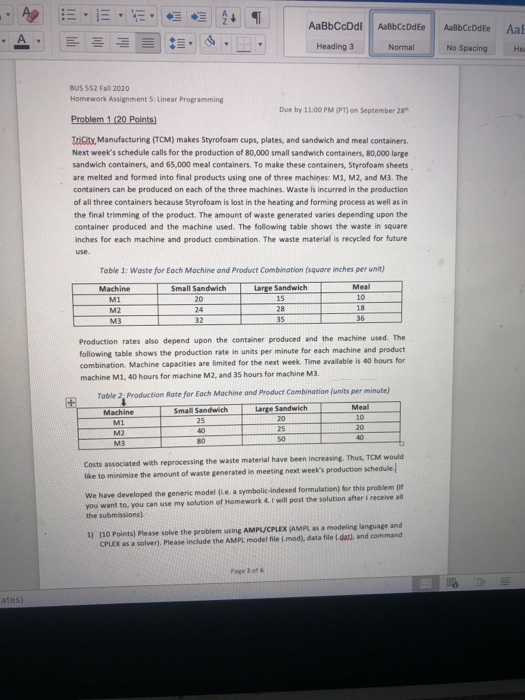

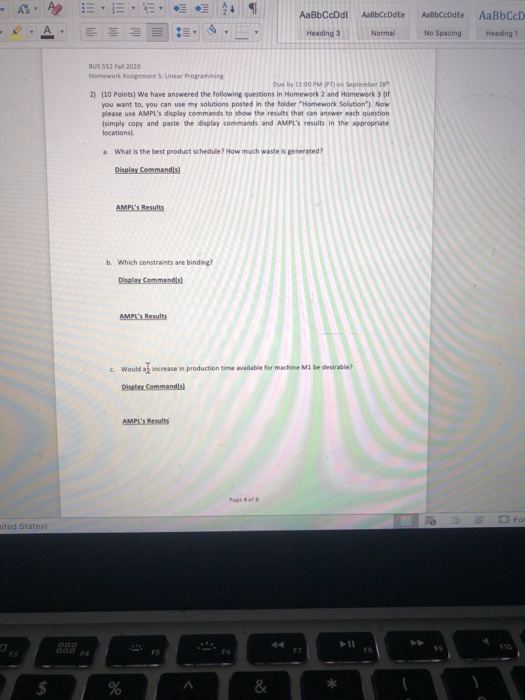

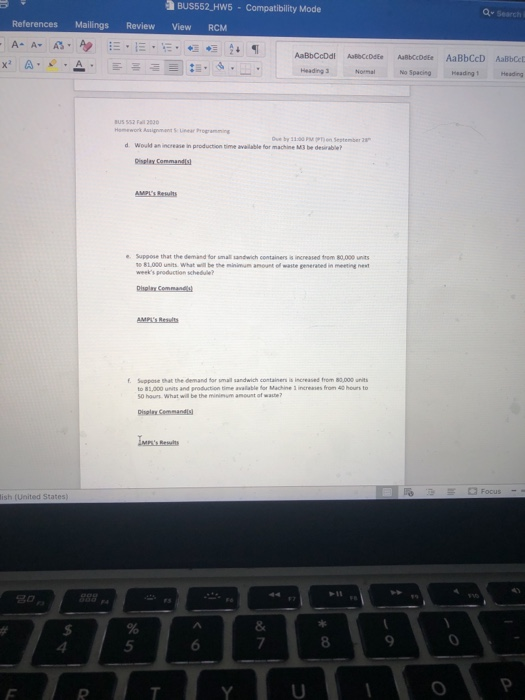

N AaBb CcDdi AaBbCcDdEe ABCcDdEe Aal Heading 3 Normal No Spacing BUS 552 Fall 2020 Homework Assignment S: Linear Programming Due by 11:00 PM (PT) on September 28 Problem 1/20 Points) Today, Manufacturing (TCM) makes Styrofoam cups, plates, and sandwich and meal containers. Next week's schedule calls for the production of 80,000 small sandwich containers, 80,000 large sandwich containers, and 65,000 meal containers. To make these containers, Styrofoam sheets are melted and formed into final products using one of three machines: M1, M2, and M3. The containers can be produced on each of the three machines. Waste is incurred in the production of all three containers because Styrofoam is lost in the heating and forming process as well as in the final trimming of the product. The amount of waste generated varies depending upon the container produced and the machine used. The following table shows the waste in square inches for each machine and product combination. The waste material is recycled for future use. Table 1: Waste for Each Machine and Product Combination (square inches per unit) Machine Small Sandwich Large Sandwich Meal MI 20 15 10 M2 24 28 18 M3 32 35 36 Production rates also depend upon the container produced and the machine used. The following table shows the production rate in units per minute for each machine and product combination Machine capacities are limited for the next week. Time available is 40 hours for machine M1, 40 hours for machine M2, and 35 hours for machine M3. Table 2 Production Rate for Each Machine and Product Combination (units per minute) Machine Small Sandwich Large Sandwich Meal M1 25 20 10 M2 40 25 20 M3 50 Costs associated with reprocessing the waste material have been increasing. Thus, TCM would like to minimize the amount of waste generated in meeting next week's production schedule. We have developed the generic modelfi.e. a symbolic-Indexed formulation) for this problem of you want to, you can use my solution of Homework 4. I will post the solution after I receive all the submissions) 1) (10 Points) Please solve the problem using AMPL/CPLEX AMPL as a modeling language and CPLEX as a solver). Please include the AMPL model file.mod), data file date, and command Page 2 of 6 ates) Ways Review View RCM . A AaBbCcDdi AaBbCcDdEe AaBbCcDdfe Heading 3 Normal No Spacing Page 2 of 6 BUS 552 Fall 2020 Homework Assignment 5 Linear Programming Due by 11:00 PM (PT) on September 28 script (run) in this Word document (simply copy and paste your answers in the appropriate locations) Model L.mod) Data dal Command Script.run) IF A AaBb CcDdi AalbCcDdEe AaBbc dee AaBbCcD Heading 3 Normal No Spacing Heading 1 BUS 552 Fal 2020 Homework Assignment 5: Linear Programming Due by 11:00 PM (PT) on September 28 2) (10 Points) We have answered the following questions in Homework 2 and Homework 3 if you want to, you can use my solutions posted in the folder "Homework Solution"). Now please use AMPL's display commands to show the results that can answer each question (simply copy and paste the display commands and AMPL's results in the appropriate locations 2. What is the best product schedule? How much waste is generated? Display Commands AMPL's Results b. Which constraints are binding? Display Commands AMPL's Results c. Would increase in production time walable for machine Ml be desirable? Display Commands AMPL's Results O For ited States) $ % & BUS552_HW5 - Compatibility Mode References Mailings Review View RCM - A- A+ AS E. AaBbCeDdl ABCDE Abcode x Aa Bbcc Aabbcc Heading Heading NO No Spacing BUS 5200 How to Duby 1 on estem d. Would increase in production time available for machines be desirable Display Commands AMPUR Suppose that the demand for all andwich containers increased from 10.000 units 10 81.000 is what will be the minimum amount of waste generated in meeting week's production schedule? Display Command AMPA Red Suppose that the demand format sandwich containers is increased from 80,000 units to $1.000 units and production timewable for an increases from 4 hours to 50 hours. What will be the minimum amount of wate? DlCommand lish (United States) Focus S 5 6 8 F T Y BUS562_HW5 - Compatibility Mode Qu ces Mailings Review View RCM AS E. 4+ AaBbc dee AaBb Ccode AaBbCcD A AaBbCcDdi Heading Normal No Spacing Heading 1 BUS 552 Fall 2020 Homework Assignment near Programming Due by 1100 PM (PT) on September The waste generated by the production of large sandwich containers using machine M2 is 28 square inches per unit. How much should this unit waste have to change to make it worthwhile to produce large sandwich containers using machine M2? Display Commands AMPL's Results h. Suppose the waste generated by production of small sandwich containers using machine MA decreases from 20 square inches per unit to 18 square Inches per unit and the waste generated by production of large sandwich containers using machine M2 decreases from 28 square Inches per unit to 21 square inches per unit will the optimal production plan change? Display Command AMPE'S Results I Focus ted States) N AaBb CcDdi AaBbCcDdEe ABCcDdEe Aal Heading 3 Normal No Spacing BUS 552 Fall 2020 Homework Assignment S: Linear Programming Due by 11:00 PM (PT) on September 28 Problem 1/20 Points) Today, Manufacturing (TCM) makes Styrofoam cups, plates, and sandwich and meal containers. Next week's schedule calls for the production of 80,000 small sandwich containers, 80,000 large sandwich containers, and 65,000 meal containers. To make these containers, Styrofoam sheets are melted and formed into final products using one of three machines: M1, M2, and M3. The containers can be produced on each of the three machines. Waste is incurred in the production of all three containers because Styrofoam is lost in the heating and forming process as well as in the final trimming of the product. The amount of waste generated varies depending upon the container produced and the machine used. The following table shows the waste in square inches for each machine and product combination. The waste material is recycled for future use. Table 1: Waste for Each Machine and Product Combination (square inches per unit) Machine Small Sandwich Large Sandwich Meal MI 20 15 10 M2 24 28 18 M3 32 35 36 Production rates also depend upon the container produced and the machine used. The following table shows the production rate in units per minute for each machine and product combination Machine capacities are limited for the next week. Time available is 40 hours for machine M1, 40 hours for machine M2, and 35 hours for machine M3. Table 2 Production Rate for Each Machine and Product Combination (units per minute) Machine Small Sandwich Large Sandwich Meal M1 25 20 10 M2 40 25 20 M3 50 Costs associated with reprocessing the waste material have been increasing. Thus, TCM would like to minimize the amount of waste generated in meeting next week's production schedule. We have developed the generic modelfi.e. a symbolic-Indexed formulation) for this problem of you want to, you can use my solution of Homework 4. I will post the solution after I receive all the submissions) 1) (10 Points) Please solve the problem using AMPL/CPLEX AMPL as a modeling language and CPLEX as a solver). Please include the AMPL model file.mod), data file date, and command Page 2 of 6 ates) Ways Review View RCM . A AaBbCcDdi AaBbCcDdEe AaBbCcDdfe Heading 3 Normal No Spacing Page 2 of 6 BUS 552 Fall 2020 Homework Assignment 5 Linear Programming Due by 11:00 PM (PT) on September 28 script (run) in this Word document (simply copy and paste your answers in the appropriate locations) Model L.mod) Data dal Command Script.run) IF A AaBb CcDdi AalbCcDdEe AaBbc dee AaBbCcD Heading 3 Normal No Spacing Heading 1 BUS 552 Fal 2020 Homework Assignment 5: Linear Programming Due by 11:00 PM (PT) on September 28 2) (10 Points) We have answered the following questions in Homework 2 and Homework 3 if you want to, you can use my solutions posted in the folder "Homework Solution"). Now please use AMPL's display commands to show the results that can answer each question (simply copy and paste the display commands and AMPL's results in the appropriate locations 2. What is the best product schedule? How much waste is generated? Display Commands AMPL's Results b. Which constraints are binding? Display Commands AMPL's Results c. Would increase in production time walable for machine Ml be desirable? Display Commands AMPL's Results O For ited States) $ % & BUS552_HW5 - Compatibility Mode References Mailings Review View RCM - A- A+ AS E. AaBbCeDdl ABCDE Abcode x Aa Bbcc Aabbcc Heading Heading NO No Spacing BUS 5200 How to Duby 1 on estem d. Would increase in production time available for machines be desirable Display Commands AMPUR Suppose that the demand for all andwich containers increased from 10.000 units 10 81.000 is what will be the minimum amount of waste generated in meeting week's production schedule? Display Command AMPA Red Suppose that the demand format sandwich containers is increased from 80,000 units to $1.000 units and production timewable for an increases from 4 hours to 50 hours. What will be the minimum amount of wate? DlCommand lish (United States) Focus S 5 6 8 F T Y BUS562_HW5 - Compatibility Mode Qu ces Mailings Review View RCM AS E. 4+ AaBbc dee AaBb Ccode AaBbCcD A AaBbCcDdi Heading Normal No Spacing Heading 1 BUS 552 Fall 2020 Homework Assignment near Programming Due by 1100 PM (PT) on September The waste generated by the production of large sandwich containers using machine M2 is 28 square inches per unit. How much should this unit waste have to change to make it worthwhile to produce large sandwich containers using machine M2? Display Commands AMPL's Results h. Suppose the waste generated by production of small sandwich containers using machine MA decreases from 20 square inches per unit to 18 square Inches per unit and the waste generated by production of large sandwich containers using machine M2 decreases from 28 square Inches per unit to 21 square inches per unit will the optimal production plan change? Display Command AMPE'S Results I Focus ted States)