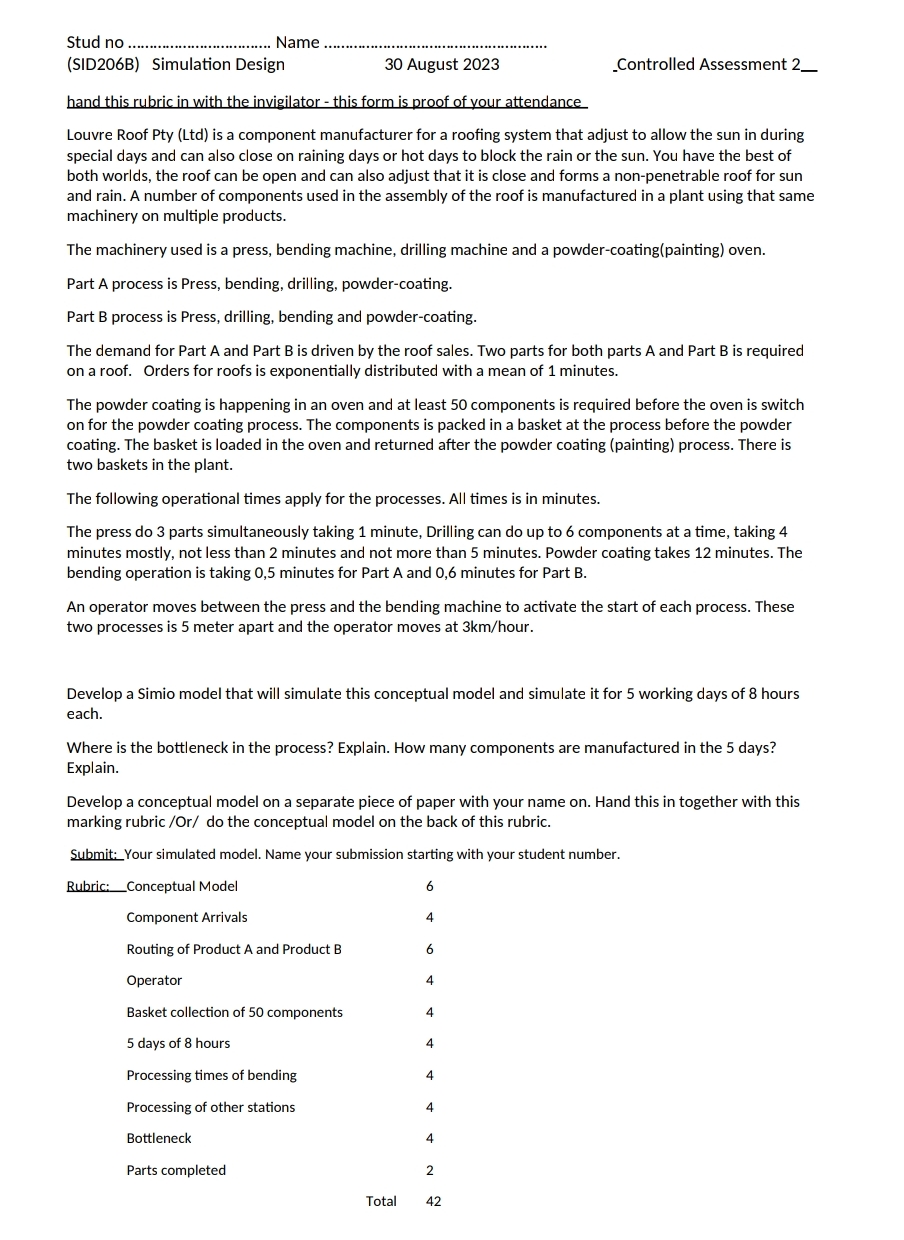

Question: Name ( SID 2 0 6 B ) Simulation Design 3 0 August 2 0 2 3 _ Controlled Assessment 2 hand this rubric in

Name

SIDB Simulation Design

August

Controlled Assessment

hand this rubric in with the invigilator this form is proof of your attendance.

Louvre Roof Pty Ltd is a component manufacturer for a roofing system that adjust to allow the sun in during

special days and can also close on raining days or hot days to block the rain or the sun. You have the best of

both worlds, the roof can be open and can also adjust that it is close and forms a nonpenetrable roof for sun

and rain. A number of components used in the assembly of the roof is manufactured in a plant using that same

machinery on multiple products.

The machinery used is a press, bending machine, drilling machine and a powdercoatingpainting oven.

Part A process is Press, bending, drilling, powdercoating.

Part B process is Press, drilling, bending and powdercoating.

The demand for Part A and Part B is driven by the roof sales. Two parts for both parts A and Part B is required

on a roof. Orders for roofs is exponentially distributed with a mean of minutes.

The powder coating is happening in an oven and at least components is required before the oven is switch

on for the powder coating process. The components is packed in a basket at the process before the powder

coating. The basket is loaded in the oven and returned after the powder coating painting process. There is

two baskets in the plant.

The following operational times apply for the processes. All times is in minutes.

The press do parts simultaneously taking minute, Drilling can do up to components at a time, taking

minutes mostly, not less than minutes and not more than minutes. Powder coating takes minutes. The

bending operation is taking minutes for Part A and minutes for Part

An operator moves between the press and the bending machine to activate the start of each process. These

two processes is meter apart and the operator moves at our.

Develop a simio model that will simulate this conceptual model and simulate it for working days of hours

each.

Where is the bottleneck in the process? Explain. How many components are manufactured in the days?

Explain.

Develop a conceptual model on a separate piece of paper with your name on Hand this in together with this

marking rubric Or do the conceptual model on the back of this rubric.

Submit:Your simulated model. Name your submission starting with your student number.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock