Question: | ndustrial and System Engineering ISE 3 2 4 ABC company produces different type of products such as milk, fruit nectar and fruit juice. The

ndustrial and System Engineering

ISE

ABC company produces different type of products such as milk, fruit nectar and fruit juice. The fruit

nectar production is as follows:

The production process of the fruit nectar begins with transporting the pulp supply from the raw

material warehouse to a temporary storage located m from the preparation area. The raw material

waits for forklift to come.

The pulp is transported using a forklift to the preparation area. In this area, water is added to the tank to

enable the suction process until the mix tank. Sugar, pepsin, citric and ascorbic acid are added,

according to the formulation manuals. Then, the content in the tank is mixed for min

A sample from the mix is sent to lab analysis for determining levels of acidity, pHBx degrees Brix and

viscosity. After a positive result from the analysis, the mix is moved to homogenized and pasteurized

area where it is homogenized and pasteurized, to psi and @C@C respectively.

Simultaneously, in a secondary line, the bottles are transported from the warehouse to the preparation

bottle area and stay in a waiting zone while a conveyor belt provides the supply of bottles. Once the

conveyor belt has enough space to locate the new bottles, the forklift moves again to this zone to locate

the bottles in the dispenser machine. This machine moves the bottles to the washing area where bottles

are cleaned and vaporized at a fixed temperature and later transported to filling area.

Once the nectar is pasteurized, it is packed at a temperature between @C and @C and transported to

filling area. The process starts with the filler machine and continues to an encapsulated machine. Once

the bottle is filled, heated, and capped, it transported into a cooling zone where it cooled for min

Then, the product reaches a temperature below to @C acidity pH@Bx and

viscosity

Finally, the product is moved to labeling area where it is labeled, and manual inspection is performed.

The nectar is transported to the packing machine zone, where the product is organized in packages

according to the desired format or units per box Once this operation is finished, the packages

are located on a cardboard tray and sent to an oven. After the seal and the code are inspected, the

product is stowed and delivered to a finished products warehouse and are ready for distribution

purposes.

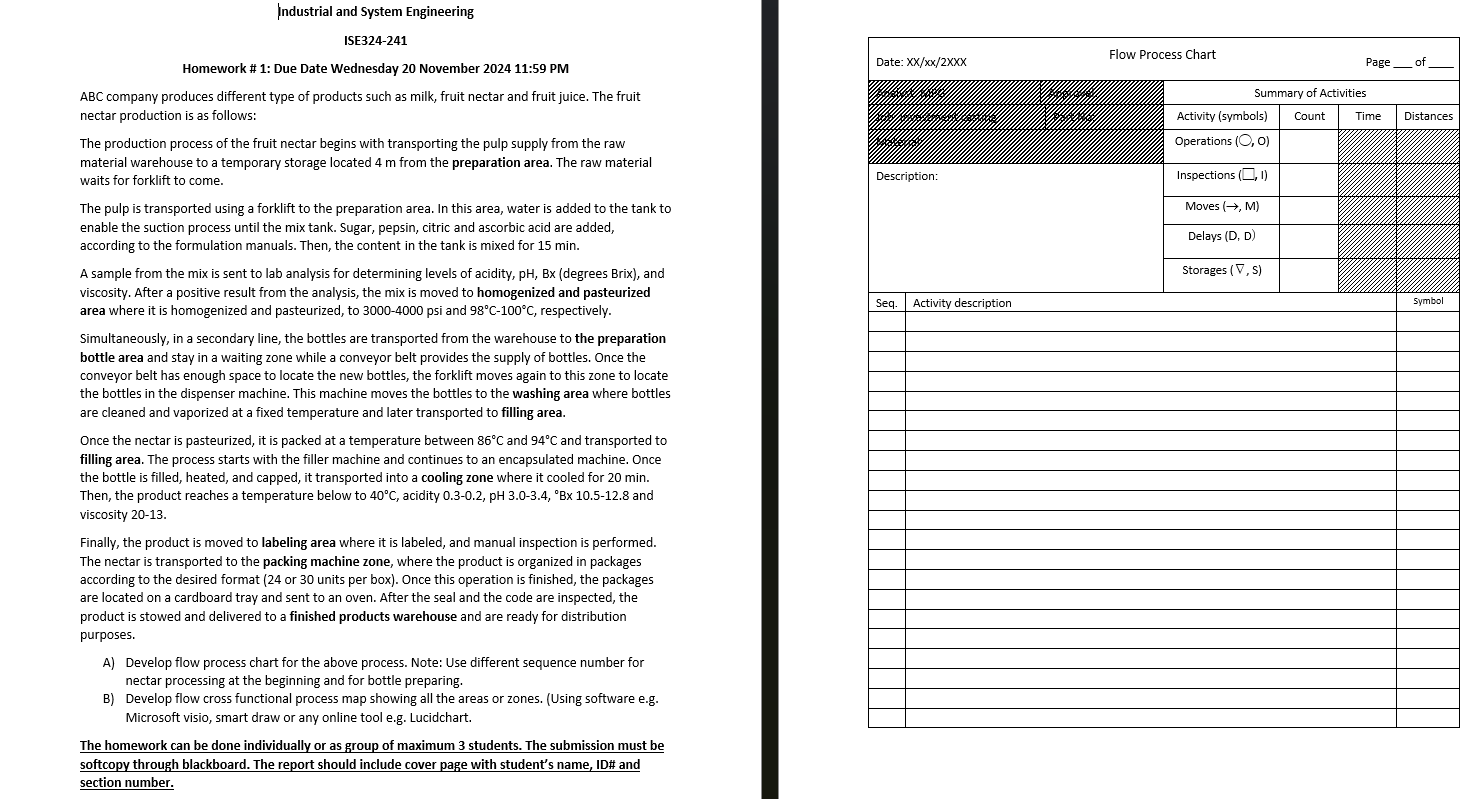

A Develop flow process chart for the above process. Note: Use different sequence number for

nectar processing at the beginning and for bottle preparing.

B Develop flow cross functional process map showing all the areas or zones. Using software eg

Microsoft visio, smart draw or any online tool eg Lucidchart.

The homework can be done individually or as group of maximum students. The submission must be

softcopy through blackboard. The report should include cover page with student's name, ID# and

section number.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock