Question: Need a solution to this case study using principles of Supply Chain Management. Potatoes are grown and harvested on farms in rhe Midwest and then

Need a solution to this case study using principles of Supply Chain Management.

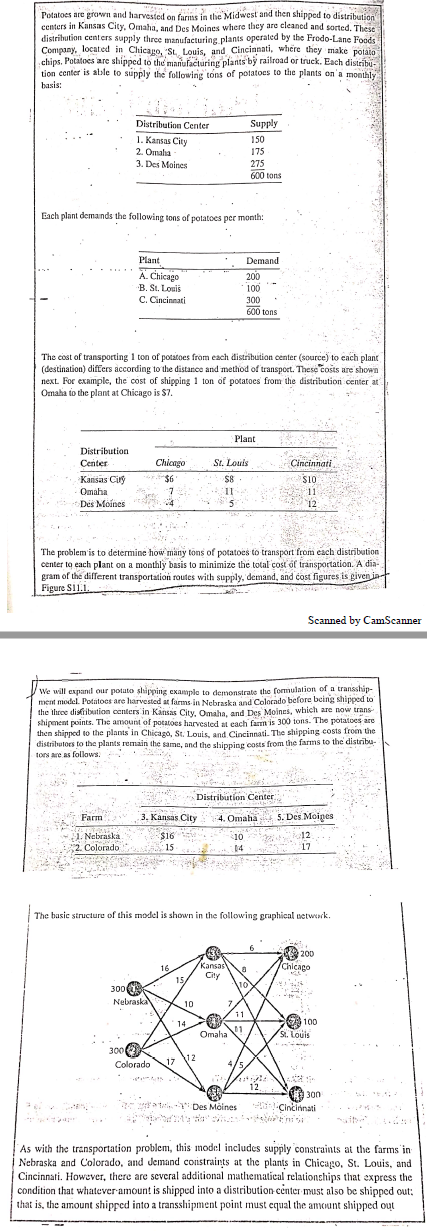

Potatoes are grown and harvested on farms in rhe Midwest and then shipped to distribution centers in Kansas City, Omaha, and Des Moines where they are cleaned and sorted. Thest distrihution centers supply three manufacturing_plants operated by the Frodo-Lane Foods Company, located in Clicago, St, Louis, and Cincinnati, where they make potato chips, Potatoes are shipped to the manufacturing plants by ratlroad or truck. Each distribution eenter is sble to supply the following tons of polatocs to the plants on a monthly Each plant demands the following tons of potatoes per month! The cost of transporting 1 ton of potitoes from esch distribution center (source) to each plant (destination) differs according to the distance and method of transpoct. These costs are shown next. For example, the cost of shipging 1 ton of potatoes from the distribution oenter at Omaka to the plant at Chicago is \$7. The problem'is to determine how many tons of potatoes to transport from each distribution center to each plant on a monthly basis to minimize the total cost of transportation. A dia gram of the different transportation routes with supply, demand, and cost figures is given in- Figure S11.1. Scanned by CamScanner Nebraska and Colorado, and Jemand conistraints at the plants in Chicaro, St. Louis, and Cincinnati. However, there are several additional mathematical relationships that express the condition that whatever-amount is shipped into a distribution cnter must also be shipped out: that is, the amount shipped into a transshipment point must equal the amount slipped out

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts