Question: Need answer and step for question 5 For the next two questions, you must consider Product P which is produced by both the Machining Department

Need answer and step for question 5

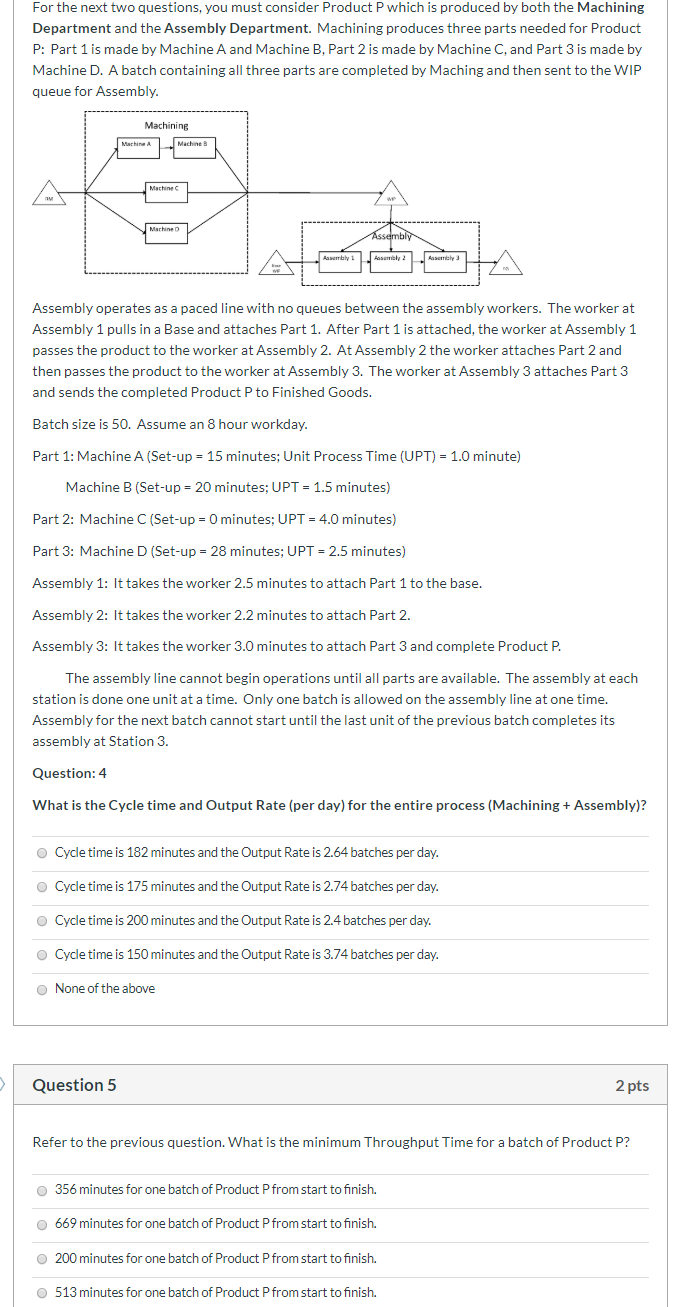

For the next two questions, you must consider Product P which is produced by both the Machining Department and the Assembly Department. Machining produces three parts needed for Product P: Part 1 is made by Machine A and Machine B, Part 2 is made by Machine C, and Part 3 is made by Machine D. A batch containing all three parts are completed by Maching and then sent to the WIP queue for Assembly. Machining Macho a 1 - Machine by Machines kaserleih Resumky z amek Assembly operates as a paced line with no queues between the assembly workers. The worker at Assembly 1 pulls in a Base and attaches Part 1. After Part 1 is attached, the worker at Assembly 1 passes the product to the worker at Assembly 2. At Assembly 2 the worker attaches Part 2 and then passes the product to the worker at Assembly 3. The worker at Assembly 3 attaches Part 3 and sends the completed Product P to Finished Goods. Batch size is 50. Assume an 8 hour workday. Part 1: Machine A (Set-up = 15 minutes; Unit Process Time (UPT) = 1.0 minute) Machine B (Set-up = 20 minutes: UPT = 1.5 minutes) Part 2: Machine C (Set-up = 0 minutes; UPT = 4.0 minutes) Part 3: Machine D (Set-up = 28 minutes; UPT = 2.5 minutes) Assembly 1: It takes the worker 2.5 minutes to attach Part 1 to the base. Assembly 2: It takes the worker 2.2 minutes to attach Part 2 Assembly 3: It takes the worker 3.0 minutes to attach Part 3 and complete Product P. The assembly line cannot begin operations until all parts are available. The assembly at each station is done one unit at a time. Only one batch is allowed on the assembly line at one time. Assembly for the next batch cannot start until the last unit of the previous batch completes its assembly at Station 3. Question: 4 What is the Cycle time and Output Rate (per day) for the entire process (Machining + Assembly)? Cycle time is 182 minutes and the Output Rate is 2.64 batches per day. Cycle time is 175 minutes and the Output Rate is 2.74 batches per day. Cycle time is 200 minutes and the Output Rate is 2.4 batches per day. Cycle time is 150 minutes and the Output Rate is 3.74 batches per day. None of the above Question 5 2 pts Refer to the previous question. What is the minimum Throughput Time for a batch of Product P? 356 minutes for one batch of Product Pfrom start to finish. 669 minutes for one batch of Product Pfrom start to finish. 200 minutes for one batch of Product Pfrom start to finish. 513 minutes for one batch of Product Pfrom start to finish. For the next two questions, you must consider Product P which is produced by both the Machining Department and the Assembly Department. Machining produces three parts needed for Product P: Part 1 is made by Machine A and Machine B, Part 2 is made by Machine C, and Part 3 is made by Machine D. A batch containing all three parts are completed by Maching and then sent to the WIP queue for Assembly. Machining Macho a 1 - Machine by Machines kaserleih Resumky z amek Assembly operates as a paced line with no queues between the assembly workers. The worker at Assembly 1 pulls in a Base and attaches Part 1. After Part 1 is attached, the worker at Assembly 1 passes the product to the worker at Assembly 2. At Assembly 2 the worker attaches Part 2 and then passes the product to the worker at Assembly 3. The worker at Assembly 3 attaches Part 3 and sends the completed Product P to Finished Goods. Batch size is 50. Assume an 8 hour workday. Part 1: Machine A (Set-up = 15 minutes; Unit Process Time (UPT) = 1.0 minute) Machine B (Set-up = 20 minutes: UPT = 1.5 minutes) Part 2: Machine C (Set-up = 0 minutes; UPT = 4.0 minutes) Part 3: Machine D (Set-up = 28 minutes; UPT = 2.5 minutes) Assembly 1: It takes the worker 2.5 minutes to attach Part 1 to the base. Assembly 2: It takes the worker 2.2 minutes to attach Part 2 Assembly 3: It takes the worker 3.0 minutes to attach Part 3 and complete Product P. The assembly line cannot begin operations until all parts are available. The assembly at each station is done one unit at a time. Only one batch is allowed on the assembly line at one time. Assembly for the next batch cannot start until the last unit of the previous batch completes its assembly at Station 3. Question: 4 What is the Cycle time and Output Rate (per day) for the entire process (Machining + Assembly)? Cycle time is 182 minutes and the Output Rate is 2.64 batches per day. Cycle time is 175 minutes and the Output Rate is 2.74 batches per day. Cycle time is 200 minutes and the Output Rate is 2.4 batches per day. Cycle time is 150 minutes and the Output Rate is 3.74 batches per day. None of the above Question 5 2 pts Refer to the previous question. What is the minimum Throughput Time for a batch of Product P? 356 minutes for one batch of Product Pfrom start to finish. 669 minutes for one batch of Product Pfrom start to finish. 200 minutes for one batch of Product Pfrom start to finish. 513 minutes for one batch of Product Pfrom start to finishStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock