Question: need answer ASAP. thank you who answer this question! BUS 306-Management Science - Case 2 Hopping Gnome Brewing Company produces several different types of beer

need answer ASAP. thank you who answer this question!

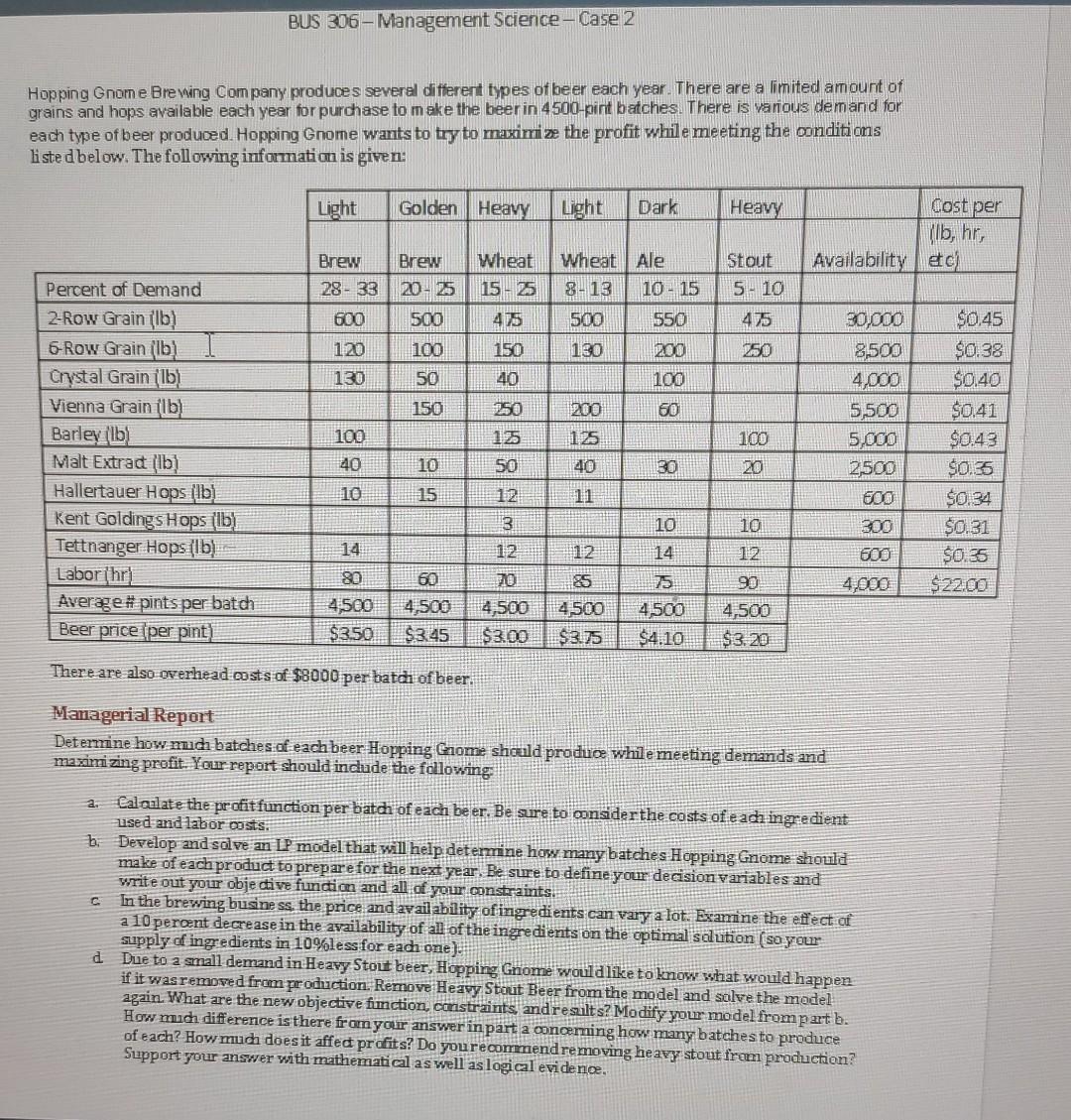

BUS 306-Management Science - Case 2 Hopping Gnome Brewing Company produces several different types of beer each year. There are a limited amount of grains and hops available each year for purchase to make the beer in 4500-pint batches. There is various demand for each type of beer produced. Hopping Gnome wants to try to maximize the profit while meeting the conditions listed below. The following informatim is given: Light Golden Heavy Light Dark Heavy Cost per Ylb, hr, Availability etc Brew Brew 28 - 33 Wheat 15 - 25 Stout 5-10 475 600 475 20-25 500 100 50 Wheat Ale 8-13 10 - 15 500 550 130 200 100 120 250 150 40 130 150 200 60 100 Percent of Demand 2-Row Grain (lb) 6- Row Grain (lb) Crystal Grain (lb) Vienna Grain (lb) Barley (lb) Malt Extract (lb) Hallertauer Hops (lb) Kent Goldings Hops (lb) Tettnanger Hops (lb) Laborihr) Average #pints per batch Beer price per pint) 100 40 10 30,000 8,500 4,000 5,500 5,000 2,500 600 300 600 4,000 125 40 11 10 $0.45 $0.38 $0.40 $0.41 $0.43 $0.5 $0.34 $0.31 $0.35 $22.00 39981999-8889 301 20 15 10 10 14 14 12 80 4,500 $3.50 60 4,500 $345 4,500 $3.00 85 4,500 $3.75 75 4,500 $4.10 90 4,500 $3.20 There are also overhead costs of $8000 per batch of beer. Managerial Report Determine how much batches of each beer Hopping Gome should produce while meeting demands and maximizing profit. Your report should include the following a. Calcalate the profit function per batch of each beer. Be sure to considerthe costs of each ingredient used and labor costs. b Develop and solve an LP model that will help determine how many batches Hopping Gnome should make of each product to prepare for the next year. Be sure to define your decision variables and write out your objective function and all of your constraints. In the brewing business, the price and availability of ingredients can vary a lot. Examine the effect of a 10 percent decrease in the availability of all of the ingredients on the optimal solution (so your supply of ingredients in 10%less for each one). d Due to a small demand in Heavy Stout beer, Hopping Gnome would like to know what would happen if it wasremoved from production. Remove Heavy Stout Beer from the model and solve the model again. What are the new objective function, constraints, andresults? Modify your model frompart b. How much difference is there from your answer inpart a concerning how many batches to produce of each? How much does it affed profits? Do you recommend removing heavy stout from production? Support your answer with mathematical as well as logical evidence, BUS 306-Management Science - Case 2 Hopping Gnome Brewing Company produces several different types of beer each year. There are a limited amount of grains and hops available each year for purchase to make the beer in 4500-pint batches. There is various demand for each type of beer produced. Hopping Gnome wants to try to maximize the profit while meeting the conditions listed below. The following informatim is given: Light Golden Heavy Light Dark Heavy Cost per Ylb, hr, Availability etc Brew Brew 28 - 33 Wheat 15 - 25 Stout 5-10 475 600 475 20-25 500 100 50 Wheat Ale 8-13 10 - 15 500 550 130 200 100 120 250 150 40 130 150 200 60 100 Percent of Demand 2-Row Grain (lb) 6- Row Grain (lb) Crystal Grain (lb) Vienna Grain (lb) Barley (lb) Malt Extract (lb) Hallertauer Hops (lb) Kent Goldings Hops (lb) Tettnanger Hops (lb) Laborihr) Average #pints per batch Beer price per pint) 100 40 10 30,000 8,500 4,000 5,500 5,000 2,500 600 300 600 4,000 125 40 11 10 $0.45 $0.38 $0.40 $0.41 $0.43 $0.5 $0.34 $0.31 $0.35 $22.00 39981999-8889 301 20 15 10 10 14 14 12 80 4,500 $3.50 60 4,500 $345 4,500 $3.00 85 4,500 $3.75 75 4,500 $4.10 90 4,500 $3.20 There are also overhead costs of $8000 per batch of beer. Managerial Report Determine how much batches of each beer Hopping Gome should produce while meeting demands and maximizing profit. Your report should include the following a. Calcalate the profit function per batch of each beer. Be sure to considerthe costs of each ingredient used and labor costs. b Develop and solve an LP model that will help determine how many batches Hopping Gnome should make of each product to prepare for the next year. Be sure to define your decision variables and write out your objective function and all of your constraints. In the brewing business, the price and availability of ingredients can vary a lot. Examine the effect of a 10 percent decrease in the availability of all of the ingredients on the optimal solution (so your supply of ingredients in 10%less for each one). d Due to a small demand in Heavy Stout beer, Hopping Gnome would like to know what would happen if it wasremoved from production. Remove Heavy Stout Beer from the model and solve the model again. What are the new objective function, constraints, andresults? Modify your model frompart b. How much difference is there from your answer inpart a concerning how many batches to produce of each? How much does it affed profits? Do you recommend removing heavy stout from production? Support your answer with mathematical as well as logical evidence

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts