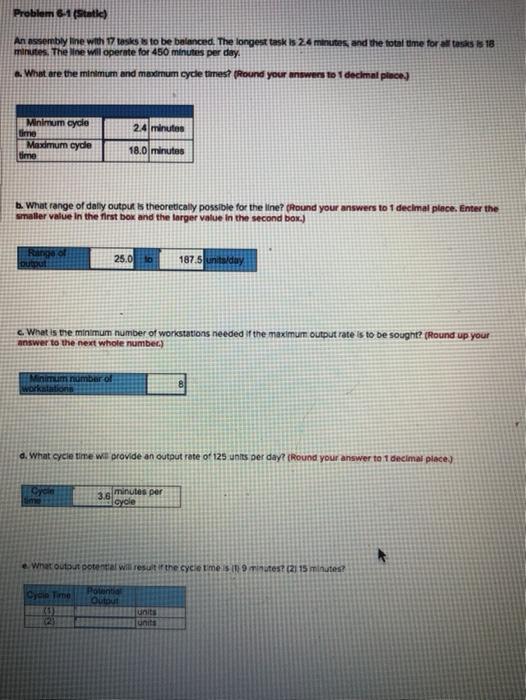

Question: Need E. sorry, need B-E: Problem 6-1 (State) An assembly ime with 17 tasks to be balanced. The longest task is 2.4 minutes and the

Need E.

sorry, need B-E:

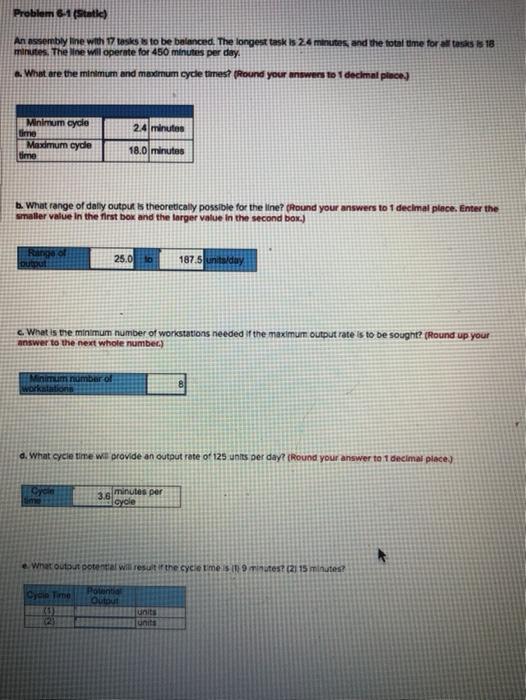

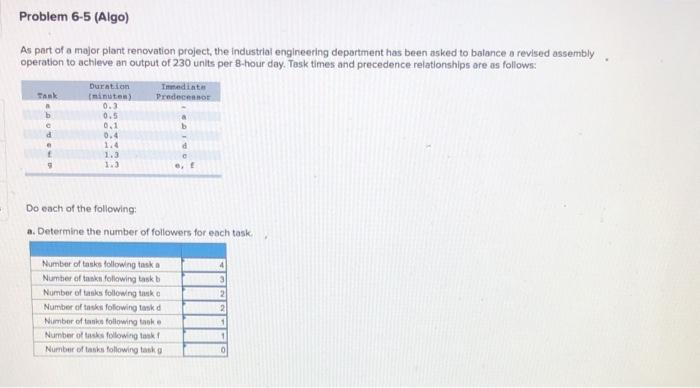

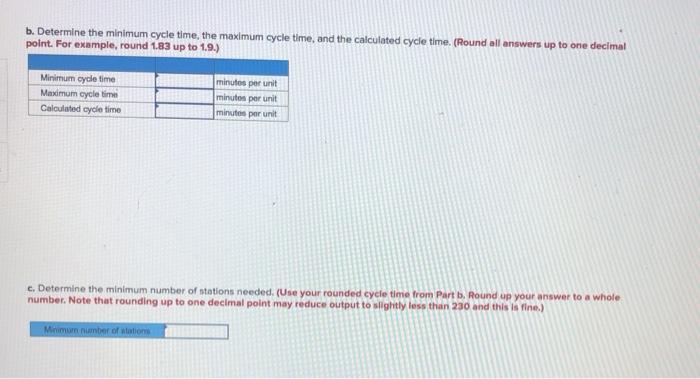

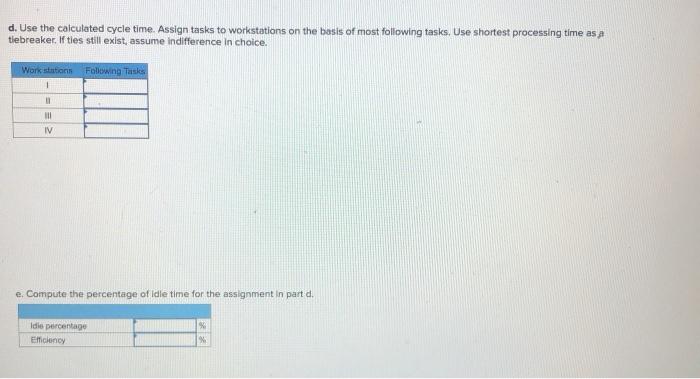

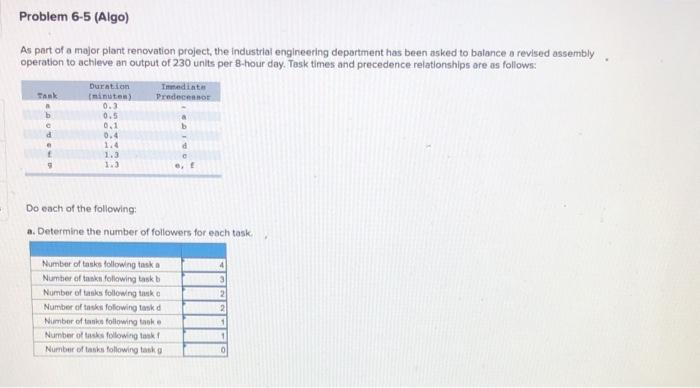

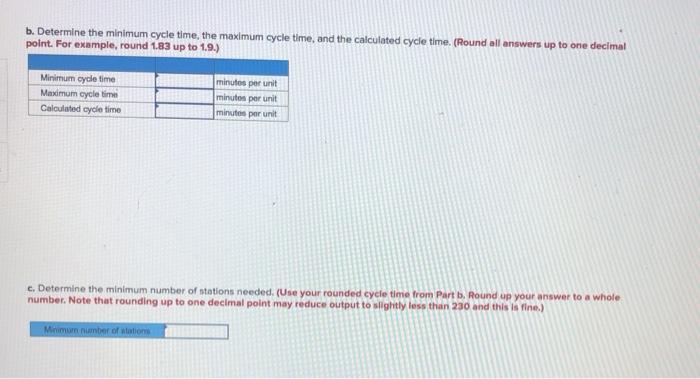

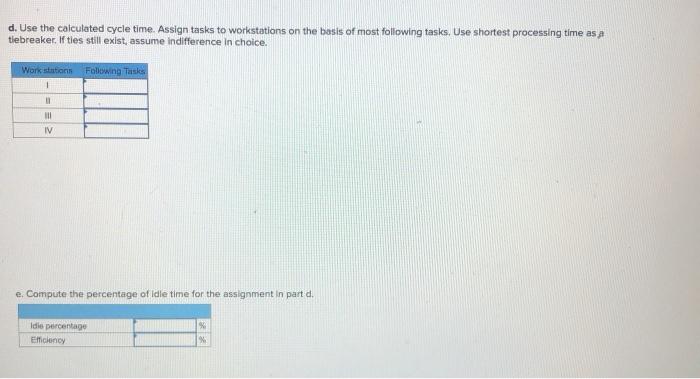

Problem 6-1 (State) An assembly ime with 17 tasks to be balanced. The longest task is 2.4 minutes and the total time for a tasks 18 minutes. The Nine will operate for 450 minutes per day a. What are the minimum and maximum cycle times? Round your answers to 1 decimal place) 24 minutes Minimum cycle time Maximum cyde time 18.0 minutes b. What range of daily output is theoreticaly possible for the line? (Round your answers to 1 decimal place. Enter the smaller value in the first box and the larger value in the second box.) Range of Output 25.0 187.5 units/day What is the minimum number of workstations needed it the maximum output rate is to be sought? (Round up your Answer to the next whole number.) Minimum number of wokatation d. What cycle time we provide an output rate of 125 units per day? [Round your answer to 1 decimal place). Cycie 3.6 minutes per yole e Whatoutout potential will result if the cycle time is notes? (2115 minutes? Cycle Time Pontia Output units units Problem 6-5 (Algo) As part of a major plant renovation project, the industrial engineering department has been asked to balance a revised assembly operation to achieve an output of 230 units per 8-hour day. Task times and precedence relationships are as follows: Tank Duration minuten) 0.3 Tmmediata Predecesso 0.5 c d 0.4 1.4 1.3 13 Do each of the following a. Determine the number of followers for each task, Number of tanks following taska Number of tanks following tasks Number of tasks following titka Number of task foliowing and Number of the following take Number of following tank Number of tanks following tasks 2 2 1 0 b. Determine the minimum cycle time, the maximum cycle time, and the calculated cycle time. (Round all answers up to one decimal point. For example, round 1.83 up to 1.9.) Minimum cycle time Maximum cycle time Calculated cycle time minutos por unit minutes per unit minutes per unit c. Determine the minimum number of stations needed. (Use your rounded cycle time from Part b. Round up your answer to a to a whole number. Note that rounding up to one decimal point may reduce output to slightly less than 230 and this is fine.) Minimum number of station d. Use the calculated cycle time. Assign tasks to workstations on the basis of most following tasks. Use shortest processing time as a tiebreaker. Ifties still exist, assume indifference in choice. Workstation Following This 1 IV e. Compute the percentage of Idle time for the assignment in part d. Idie percentage Efficiency Problem 6-1 (State) An assembly ime with 17 tasks to be balanced. The longest task is 2.4 minutes and the total time for a tasks 18 minutes. The Nine will operate for 450 minutes per day a. What are the minimum and maximum cycle times? Round your answers to 1 decimal place) 24 minutes Minimum cycle time Maximum cyde time 18.0 minutes b. What range of daily output is theoreticaly possible for the line? (Round your answers to 1 decimal place. Enter the smaller value in the first box and the larger value in the second box.) Range of Output 25.0 187.5 units/day What is the minimum number of workstations needed it the maximum output rate is to be sought? (Round up your Answer to the next whole number.) Minimum number of wokatation d. What cycle time we provide an output rate of 125 units per day? [Round your answer to 1 decimal place). Cycie 3.6 minutes per yole e Whatoutout potential will result if the cycle time is notes? (2115 minutes? Cycle Time Pontia Output units units Problem 6-5 (Algo) As part of a major plant renovation project, the industrial engineering department has been asked to balance a revised assembly operation to achieve an output of 230 units per 8-hour day. Task times and precedence relationships are as follows: Tank Duration minuten) 0.3 Tmmediata Predecesso 0.5 c d 0.4 1.4 1.3 13 Do each of the following a. Determine the number of followers for each task, Number of tanks following taska Number of tanks following tasks Number of tasks following titka Number of task foliowing and Number of the following take Number of following tank Number of tanks following tasks 2 2 1 0 b. Determine the minimum cycle time, the maximum cycle time, and the calculated cycle time. (Round all answers up to one decimal point. For example, round 1.83 up to 1.9.) Minimum cycle time Maximum cycle time Calculated cycle time minutos por unit minutes per unit minutes per unit c. Determine the minimum number of stations needed. (Use your rounded cycle time from Part b. Round up your answer to a to a whole number. Note that rounding up to one decimal point may reduce output to slightly less than 230 and this is fine.) Minimum number of station d. Use the calculated cycle time. Assign tasks to workstations on the basis of most following tasks. Use shortest processing time as a tiebreaker. Ifties still exist, assume indifference in choice. Workstation Following This 1 IV e. Compute the percentage of Idle time for the assignment in part d. Idie percentage Efficiency

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock