Question: need help example steps McBurger, Inc., wants to redesign its kitchens to improve productivity and quality Three designs, called designs K1, K2, and I are

need help example steps

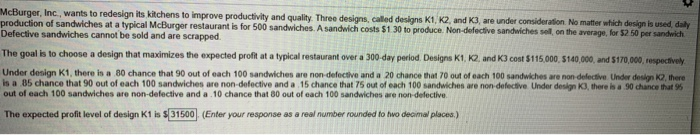

McBurger, Inc., wants to redesign its kitchens to improve productivity and quality Three designs, called designs K1, K2, and I are under consideration No matter which design is used daily production of sandwiches at a typical McBurger restaurant is for 500 sandwiches. A sandwich costs $130 to produce. Non-defective sandwiches sell on the average for $2.50 per sandwich Defective sandwiches cannot be sold and are scrapped The goal is to choose a design that maximizes the expected profit at a typical restaurant over a 300 day period. Designs K1, K2 and 3 cost $115.000, 5140,000 and 5170,000, respective Under design K1, there is a 10 chance that 90 out of each 100 sandwiches are non-defective and a 20 chance that 70 out of each 100 sandwiches are non detective Under design , there is a 35 chance that 90 out of each 100 sandwiches are non defective and a 15 chance that 75 out of each 100 sandwiches are non defective Under design there a 50 chance that out of each 100 sandwiches are non-defective and a 10 chance that 80 out of each 100 sandwiches are non-defective The expected profit level of design K1 is 5 31500 (Enter your response as a real number rounded to be deomal places)

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock