Question: Need help on Question 4 only using Excel... Thanks. Table B Standard Product Costs s. See Table C Table C Overhead Budget for 1988 a.

Need help on Question 4 only using Excel... Thanks.

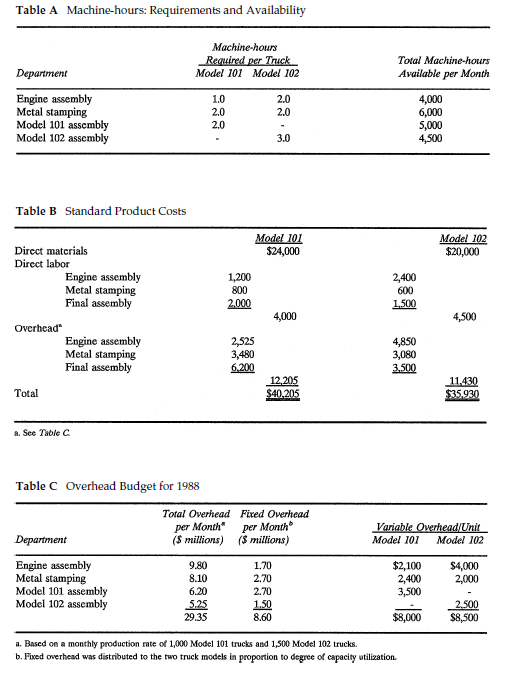

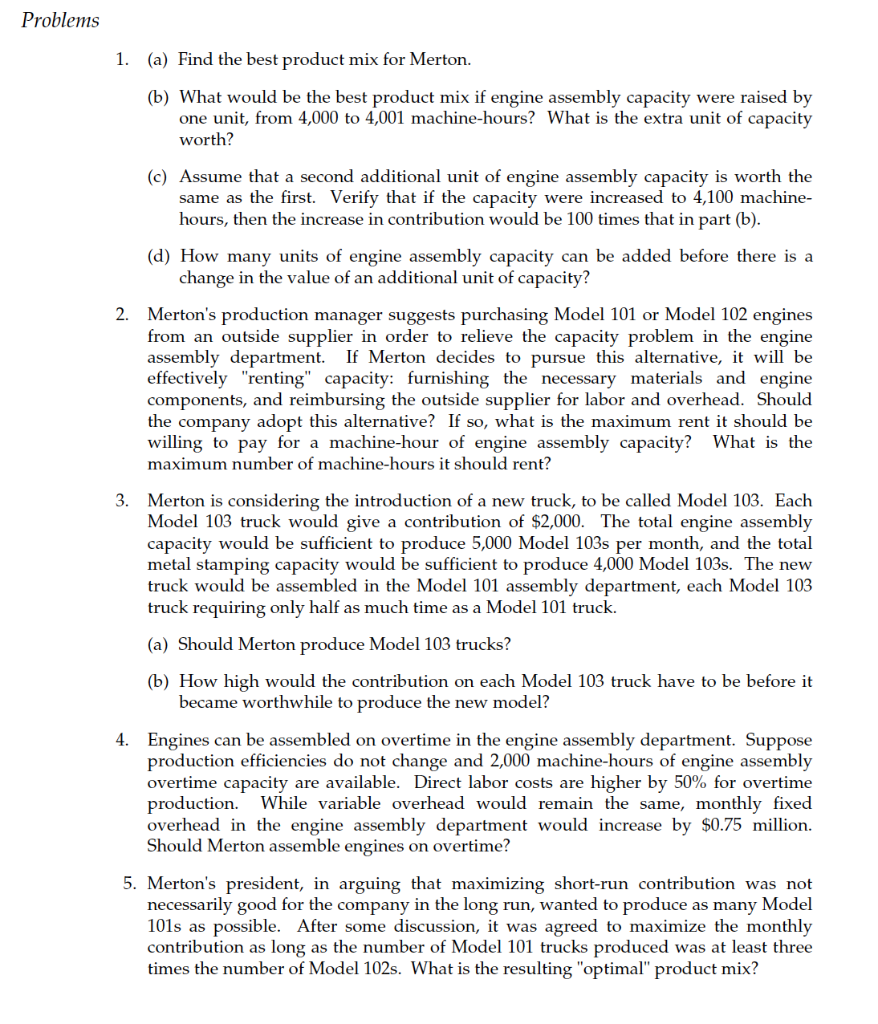

Table B Standard Product Costs s. See Table C Table C Overhead Budget for 1988 a. Bused on a monthly production rate of 1,000 Model 101 trucks and 1,500 Model 102 trucks. b. Fixed overhead was distributed to the two truck models in proportion to degree of capacity atilization. 1. (a) Find the best product mix for Merton. (b) What would be the best product mix if engine assembly capacity were raised by one unit, from 4,000 to 4,001 machine-hours? What is the extra unit of capacity worth? (c) Assume that a second additional unit of engine assembly capacity is worth the same as the first. Verify that if the capacity were increased to 4,100 machinehours, then the increase in contribution would be 100 times that in part (b). (d) How many units of engine assembly capacity can be added before there is a change in the value of an additional unit of capacity? 2. Merton's production manager suggests purchasing Model 101 or Model 102 engines from an outside supplier in order to relieve the capacity problem in the engine assembly department. If Merton decides to pursue this alternative, it will be effectively "renting" capacity: furnishing the necessary materials and engine components, and reimbursing the outside supplier for labor and overhead. Should the company adopt this alternative? If so, what is the maximum rent it should be willing to pay for a machine-hour of engine assembly capacity? What is the maximum number of machine-hours it should rent? 3. Merton is considering the introduction of a new truck, to be called Model 103. Each Model 103 truck would give a contribution of $2,000. The total engine assembly capacity would be sufficient to produce 5,000 Model 103s per month, and the total metal stamping capacity would be sufficient to produce 4,000 Model 103s. The new truck would be assembled in the Model 101 assembly department, each Model 103 truck requiring only half as much time as a Model 101 truck. (a) Should Merton produce Model 103 trucks? (b) How high would the contribution on each Model 103 truck have to be before it became worthwhile to produce the new model? 4. Engines can be assembled on overtime in the engine assembly department. Suppose production efficiencies do not change and 2,000 machine-hours of engine assembly overtime capacity are available. Direct labor costs are higher by 50% for overtime production. While variable overhead would remain the same, monthly fixed overhead in the engine assembly department would increase by $0.75 million. Should Merton assemble engines on overtime? 5. Merton's president, in arguing that maximizing short-run contribution was not necessarily good for the company in the long run, wanted to produce as many Model 101s as possible. After some discussion, it was agreed to maximize the monthly contribution as long as the number of Model 101 trucks produced was at least three times the number of Model 102s. What is the resulting "optimal" product mix? Table B Standard Product Costs s. See Table C Table C Overhead Budget for 1988 a. Bused on a monthly production rate of 1,000 Model 101 trucks and 1,500 Model 102 trucks. b. Fixed overhead was distributed to the two truck models in proportion to degree of capacity atilization. 1. (a) Find the best product mix for Merton. (b) What would be the best product mix if engine assembly capacity were raised by one unit, from 4,000 to 4,001 machine-hours? What is the extra unit of capacity worth? (c) Assume that a second additional unit of engine assembly capacity is worth the same as the first. Verify that if the capacity were increased to 4,100 machinehours, then the increase in contribution would be 100 times that in part (b). (d) How many units of engine assembly capacity can be added before there is a change in the value of an additional unit of capacity? 2. Merton's production manager suggests purchasing Model 101 or Model 102 engines from an outside supplier in order to relieve the capacity problem in the engine assembly department. If Merton decides to pursue this alternative, it will be effectively "renting" capacity: furnishing the necessary materials and engine components, and reimbursing the outside supplier for labor and overhead. Should the company adopt this alternative? If so, what is the maximum rent it should be willing to pay for a machine-hour of engine assembly capacity? What is the maximum number of machine-hours it should rent? 3. Merton is considering the introduction of a new truck, to be called Model 103. Each Model 103 truck would give a contribution of $2,000. The total engine assembly capacity would be sufficient to produce 5,000 Model 103s per month, and the total metal stamping capacity would be sufficient to produce 4,000 Model 103s. The new truck would be assembled in the Model 101 assembly department, each Model 103 truck requiring only half as much time as a Model 101 truck. (a) Should Merton produce Model 103 trucks? (b) How high would the contribution on each Model 103 truck have to be before it became worthwhile to produce the new model? 4. Engines can be assembled on overtime in the engine assembly department. Suppose production efficiencies do not change and 2,000 machine-hours of engine assembly overtime capacity are available. Direct labor costs are higher by 50% for overtime production. While variable overhead would remain the same, monthly fixed overhead in the engine assembly department would increase by $0.75 million. Should Merton assemble engines on overtime? 5. Merton's president, in arguing that maximizing short-run contribution was not necessarily good for the company in the long run, wanted to produce as many Model 101s as possible. After some discussion, it was agreed to maximize the monthly contribution as long as the number of Model 101 trucks produced was at least three times the number of Model 102s. What is the resulting "optimal" product mix

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts