Question: need help with homework using excell with steps Thermon Manufacturing Company serves the global Energy, Power Generation and Chemical markets to provide innovative solutions for

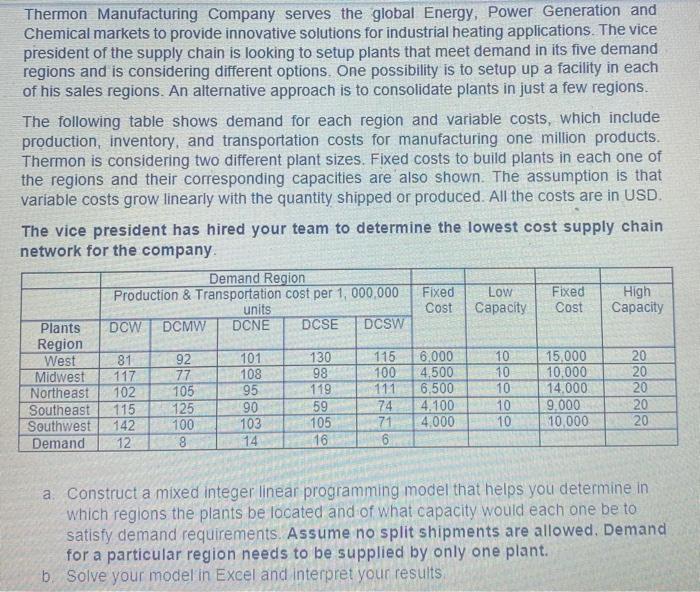

Thermon Manufacturing Company serves the global Energy, Power Generation and Chemical markets to provide innovative solutions for industrial heating applications. The vice president of the supply chain is looking to setup plants that meet demand in its five demand regions and is considering different options. One possibility is to setup up a facility in each of his sales regions. An alternative approach is to consolidate plants in just a few regions. The following table shows demand for each region and variable costs, which include production, inventory, and transportation costs for manufacturing one million products. Thermon is considering two different plant sizes. Fixed costs to build plants in each one of the regions and their corresponding capacities are also shown. The assumption is that variable costs grow linearly with the quantity shipped or produced. All the costs are in USD. The vice president has hired your team to determine the lowest cost supply chain network for the company. a. Construct a mixed integer linear programming model that helps you determine in which regions the plants be located and of what capacity would each one be to satisfy demand requirements. Assume no split shipments are allowed. Demand for a particular region needs to be supplied by only one plant. b. Solve your model in Excel and interpret your results Thermon Manufacturing Company serves the global Energy, Power Generation and Chemical markets to provide innovative solutions for industrial heating applications. The vice president of the supply chain is looking to setup plants that meet demand in its five demand regions and is considering different options. One possibility is to setup up a facility in each of his sales regions. An alternative approach is to consolidate plants in just a few regions. The following table shows demand for each region and variable costs, which include production, inventory, and transportation costs for manufacturing one million products. Thermon is considering two different plant sizes. Fixed costs to build plants in each one of the regions and their corresponding capacities are also shown. The assumption is that variable costs grow linearly with the quantity shipped or produced. All the costs are in USD. The vice president has hired your team to determine the lowest cost supply chain network for the company. a. Construct a mixed integer linear programming model that helps you determine in which regions the plants be located and of what capacity would each one be to satisfy demand requirements. Assume no split shipments are allowed. Demand for a particular region needs to be supplied by only one plant. b. Solve your model in Excel and interpret your results

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts