Question: Need help with these questions process technology 1. The picture is a simplified schematic of a hydrotreater unit. The purpose of this unit is to

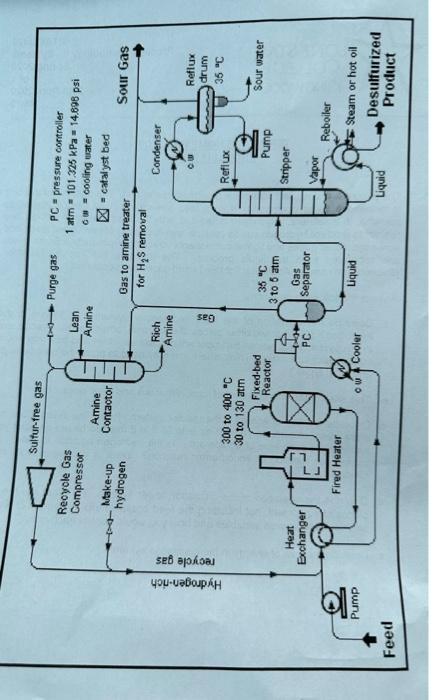

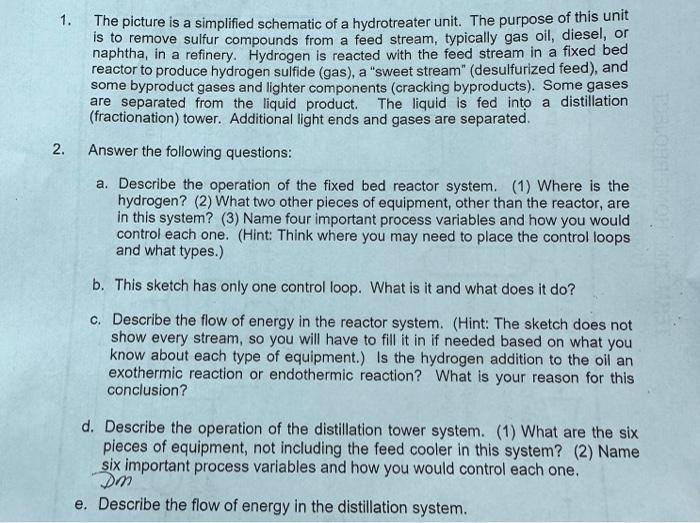

1. The picture is a simplified schematic of a hydrotreater unit. The purpose of this unit is to remove sulfur compounds from a feed stream, typically gas oil, diesel, or naphtha, in a refinery. Hydrogen is reacted with the feed stream in a fixed bed reactor to produce hydrogen sulfide (gas), a "sweet stream" (desulfurized feed), and some byproduct gases and lighter components (cracking byproducts). Some gases are separated from the liquid product. The liquid is fed into a distillation (fractionation) tower. Additional light ends and gases are separated. 2. Answer the following questions: a. Describe the operation of the fixed bed reactor system. (1) Where is the hydrogen? (2) What two other pieces of equipment, other than the reactor, are in this system? (3) Name four important process variables and how you would control each one. (Hint: Think where you may need to place the control loops and what types.) b. This sketch has only one control loop. What is it and what does it do? c. Describe the flow of energy in the reactor system. (Hint: The sketch does not show every stream, so you will have to fill it in if needed based on what you know about each type of equipment.) Is the hydrogen addition to the oil an exothermic reaction or endothermic reaction? What is your reason for this conclusion? d. Describe the operation of the distillation tower system. (1) What are the six pieces of equipment, not including the feed cooler in this system? (2) Name six important process variables and how you would control each one. e. Describe the flow of energy in the distillation system. 1. The picture is a simplified schematic of a hydrotreater unit. The purpose of this unit is to remove sulfur compounds from a feed stream, typically gas oil, diesel, or naphtha, in a refinery. Hydrogen is reacted with the feed stream in a fixed bed reactor to produce hydrogen sulfide (gas), a "sweet stream" (desulfurized feed), and some byproduct gases and lighter components (cracking byproducts). Some gases are separated from the liquid product. The liquid is fed into a distillation (fractionation) tower. Additional light ends and gases are separated. 2. Answer the following questions: a. Describe the operation of the fixed bed reactor system. (1) Where is the hydrogen? (2) What two other pieces of equipment, other than the reactor, are in this system? (3) Name four important process variables and how you would control each one. (Hint: Think where you may need to place the control loops and what types.) b. This sketch has only one control loop. What is it and what does it do? c. Describe the flow of energy in the reactor system. (Hint: The sketch does not show every stream, so you will have to fill it in if needed based on what you know about each type of equipment.) Is the hydrogen addition to the oil an exothermic reaction or endothermic reaction? What is your reason for this conclusion? d. Describe the operation of the distillation tower system. (1) What are the six pieces of equipment, not including the feed cooler in this system? (2) Name six important process variables and how you would control each one. e. Describe the flow of energy in the distillation system

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts