Question: Need help with this one this is part 2 i need help with also Part (pts) You were called on to the production for one

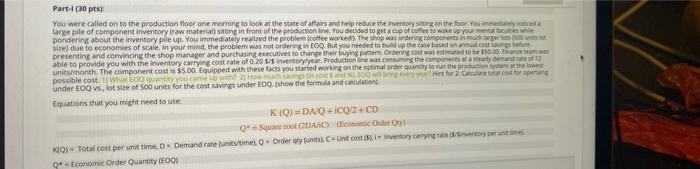

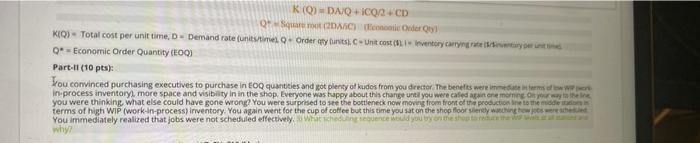

Part (pts) You were called on to the production for one morning to look at the state of artars and help reduce the inventory sitting on the food you may sa large pile of component inventory raw material sitting in front of the production line. You decided to get a cup of coffee to wake up your menu pondering about the inventory pile up. You immediately realized the problem (coffee worked). The shop was ordering components in 15.00 stre due to economies of scale. In your mind the problem was not ordering in to. Blut you needed to build up the came based on a cocaine presenting and convincing the shop manager and purchasing executives to change their buying pattern Ordering cost was estimated to be 350.00 mm able to provide you with the inventory carrying cost rate of 0 20 515 vertory year. Production in was conturing the componentes y demander units/month The component cost is $5.00. Equipped with these facts you started working on the optimal order quantity to run the productions possible costs on you come up with Wort for 2 metrar under EOQ vs. lot sure of 500 units for the cost savings under 50 how the formula and calculation Equations that you might need to use K(Q) =DA/Q+100/2+CD O" Square rootODARC) Ecode KO)- Total cost per unit time Demand rate units/timelo. Order glycost.Cunt costs. Inventory carrying to per un Economic Order Quantity (EO) K(Q) = DAQ+120/ 2CD Qaroo (DAC) code KIO) - Total cost per unit time, D. Demand rate functie Order oyunc Unit cost inventory carry yeri Q Economic Order Quantity (EOQ) Part-II (10 pts): Vou convinced purchasing executives to purchase in to quantities and got plenty of kudos from you director. The benefits were forms or in process inventoryl. more space and visibility in in the shop. Everyone was tuppy about this change until you were called in one moment you waya you were thinking what else could have gone wrong? You were surprised to see the bottleneck now moving from front of the production into the middle terms of high WIP (work-in-process) inventory. You again went for the cup of coffee but this time you sat on the shop floor slety whows were You immediately realized that jobs were not scheduled effectively Witchenende would you by on the show why Part (pts) You were called on to the production for one morning to look at the state of artars and help reduce the inventory sitting on the food you may sa large pile of component inventory raw material sitting in front of the production line. You decided to get a cup of coffee to wake up your menu pondering about the inventory pile up. You immediately realized the problem (coffee worked). The shop was ordering components in 15.00 stre due to economies of scale. In your mind the problem was not ordering in to. Blut you needed to build up the came based on a cocaine presenting and convincing the shop manager and purchasing executives to change their buying pattern Ordering cost was estimated to be 350.00 mm able to provide you with the inventory carrying cost rate of 0 20 515 vertory year. Production in was conturing the componentes y demander units/month The component cost is $5.00. Equipped with these facts you started working on the optimal order quantity to run the productions possible costs on you come up with Wort for 2 metrar under EOQ vs. lot sure of 500 units for the cost savings under 50 how the formula and calculation Equations that you might need to use K(Q) =DA/Q+100/2+CD O" Square rootODARC) Ecode KO)- Total cost per unit time Demand rate units/timelo. Order glycost.Cunt costs. Inventory carrying to per un Economic Order Quantity (EO) K(Q) = DAQ+120/ 2CD Qaroo (DAC) code KIO) - Total cost per unit time, D. Demand rate functie Order oyunc Unit cost inventory carry yeri Q Economic Order Quantity (EOQ) Part-II (10 pts): Vou convinced purchasing executives to purchase in to quantities and got plenty of kudos from you director. The benefits were forms or in process inventoryl. more space and visibility in in the shop. Everyone was tuppy about this change until you were called in one moment you waya you were thinking what else could have gone wrong? You were surprised to see the bottleneck now moving from front of the production into the middle terms of high WIP (work-in-process) inventory. You again went for the cup of coffee but this time you sat on the shop floor slety whows were You immediately realized that jobs were not scheduled effectively Witchenende would you by on the show why

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts