Question: need some help determining the answer to these 4 questions at the bottom plz help me solve. Hopefully this is a better picture! We could

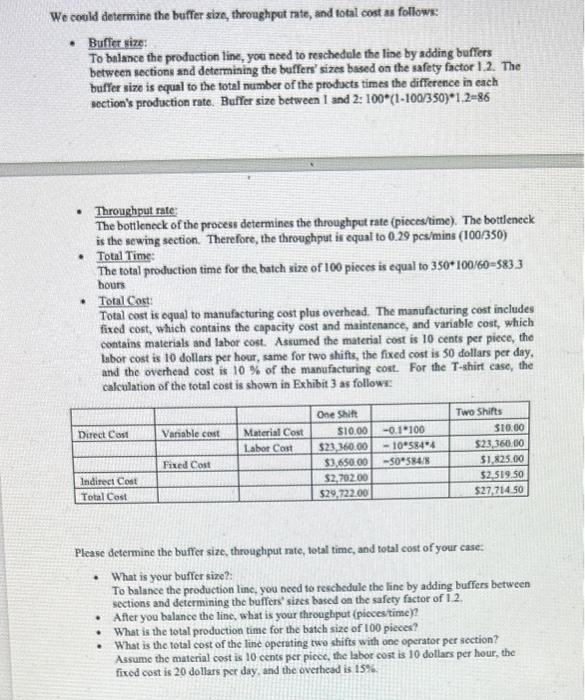

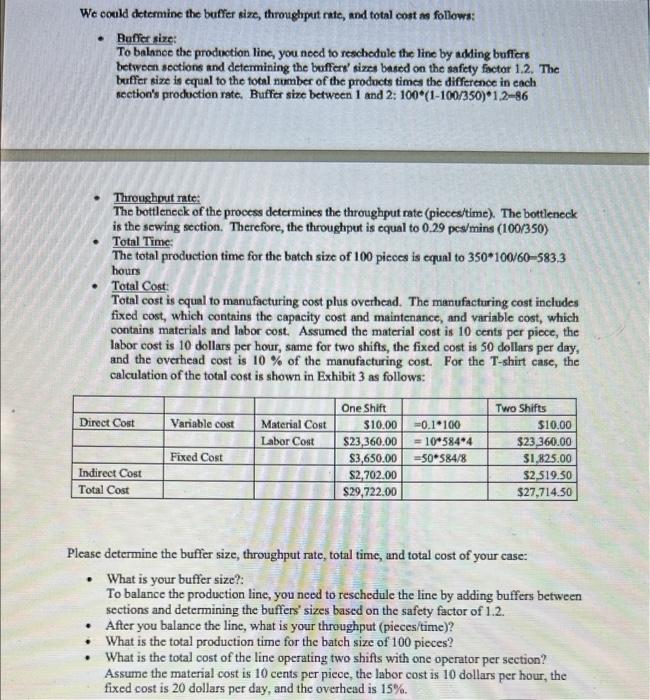

We could determine the buffer sire, throughpet mate, and total cost as follows: - Bufter size. To balance the production line, yoe need to regchedule the line by adding buffers between sections and determining the buffers' sizes based on the safety factor 1.2. The buffer size is equal to the total number of the products times the difference in each section's production rate. Buffer size between 1 and 2: 100(1100/350)1.2=86 - Throughput rate: The bottleneck of the process determines the throughput rate (piceestime). The bottleneek is the sewing section. Therefore, the throughput is equal to 0.29 pes/mins (100/350) Total Time: The total production time for the batch size of 100 picces is equal to 350+100/60=5833 hours. - Total Cost: Total cost is equal to manufacturing cost plus overhead. The manufacturing cost includes fixed cost, which contains the capacity cost and maiotenance, and variable cost, which contains materials and labor cost. Assumed the material cost is 10 cents per piece, the labor cost is 10 dollars per hour, same for two shifts, the fixed cost is 50 dollars per day, and the overhead cost is 10% of the manufacturing cost. For the T-shirt case, the calculation of the total cost is shown in Exhibit 3 as followe: Please determine the buffer size, throughput nate, total time, and total cost of your case: - What is your buffer size?: To balance the production line, you need to resehedule the line by adding buffers between sections and determining the buffers' sires based on the safety factor of 12. - After you balance the line, what is your throughput (piccestime)? - What is the total production time for the batch size of 100 picees? - What is the total cost of the line operating two shifts with one operator per section? Assume the material cost is 10 cents per picec, the labor cont is 10 dollars per hour, the fixed cost is 20 dollars per day, and the overhead is 15% We eould determine the buffer size, throughput rate, and total cost as follows: - Buffer size: To balanee the production line, you noed to reschodule the line by adding buffers between soctions and determining the buffers' sixes based on the saficty factor 1.2. The buffer size is equal to the total number of the products times the difference in each section's production rate. Buffer size between 1 and 2:100* (1100/350)1.286 - Thronghout rate: The bottleneck of the process determines the throughput rate (picces/time). The bottleneck is the sewing section. Therefore, the throughput is equal to 0.29 pes/mins (100/350) - Total Time: The total production time for the batch size of 100 pieces is equal to 350100/60583.3 hours - Total Cost: Total cost is equal to manufacturing cost plus overhend. The manufacturing cost includes fixed cost, which contnins the capacity cost and maintenance, and variable cost, which contains materials and labor cost. Assumed the material cost is 10 cents per pioce, the labor cost is 10 dollars per hour, same for two shifts, the fixed cost is 50 dollars per day, and the overhead cost is 10% of the manufacturing cost. For the T-shitt case, the calculation of the total cost is shown in Exhibit 3 as follows: Please determine the buffer size, throughput rate, total time, and total cost of your case: - What is your buffer size?: To balance the production line, you need to reschedule the line by adding buffers between sections and determining the buffers' sizes based on the safety factor of 1.2. - After you balance the line, what is your throughput (pieces/time)? - What is the total production time for the batch size of 100 pieces? - What is the total cost of the line operating two shifts with one operator per section? Assume the material cost is 10 cents per piece, the labor cost is 10 dollars per hour, the fixed cost is 20 dollars per day, and the overhead is 15%

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts