Question: Need step by step process with correct final answer and explanation. Please do it accurately 3) Recall the following problem and review its Sensitivity Report:

Need step by step process with correct final answer and explanation. Please do it accurately

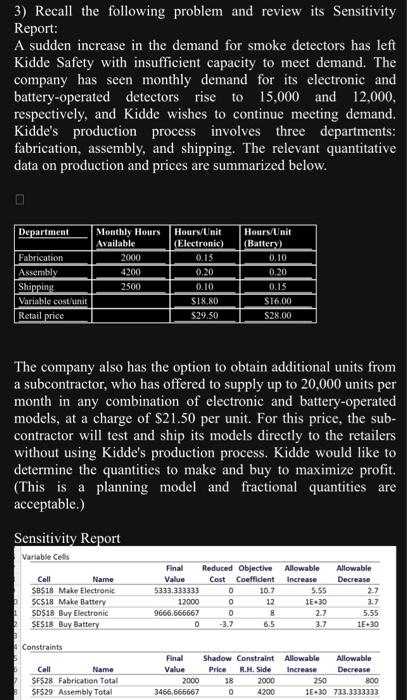

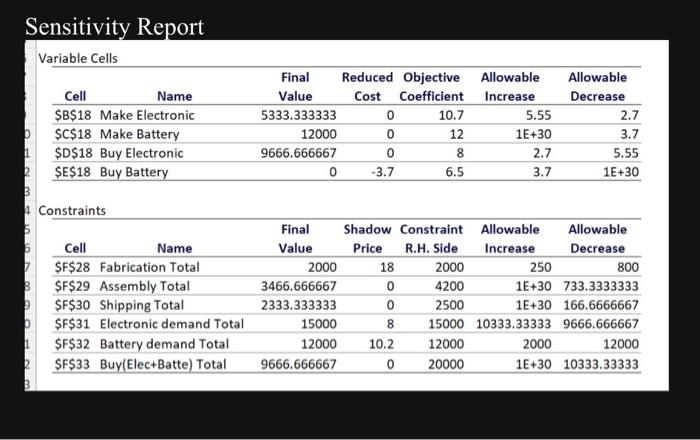

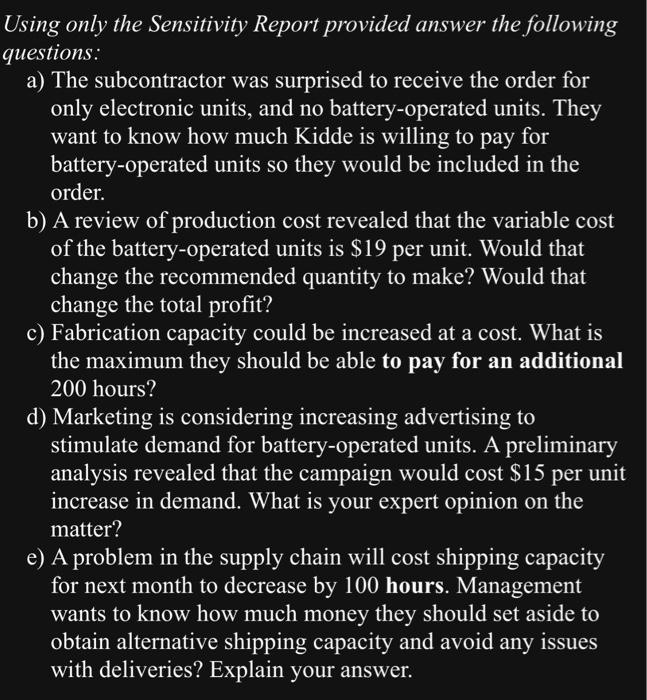

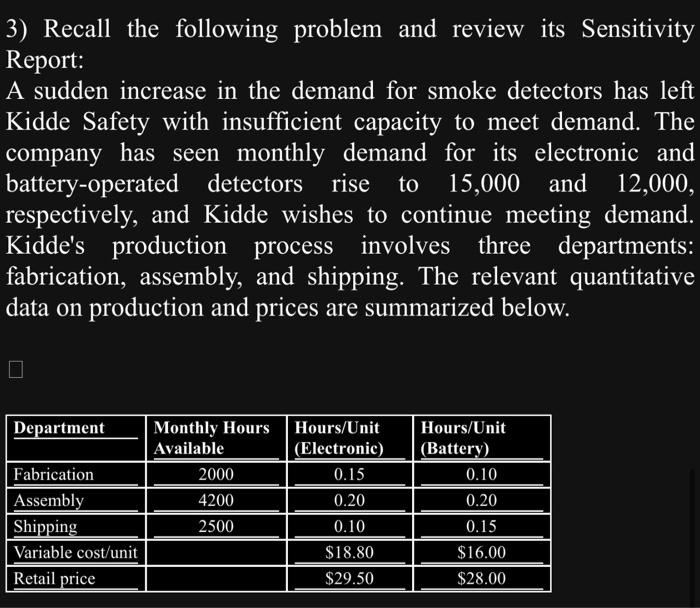

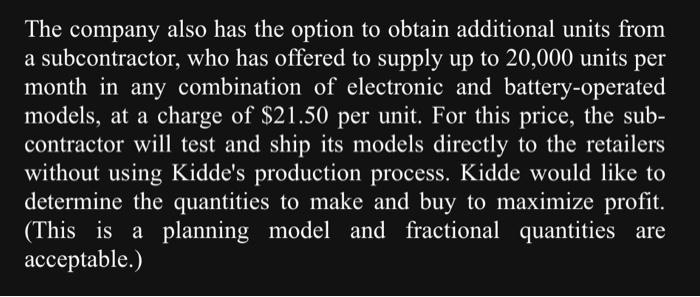

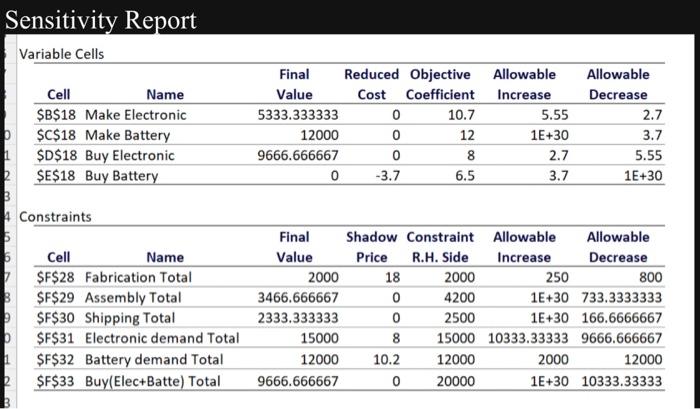

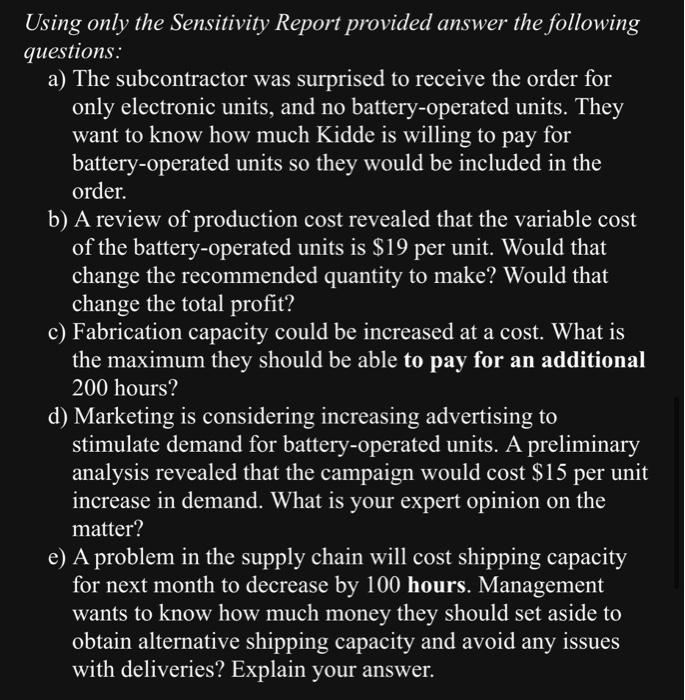

3) Recall the following problem and review its Sensitivity Report: A sudden increase in the demand for smoke detectors has left Kidde Safety with insufficient capacity to meet demand. The company has seen monthly demand for its electronic and battery-operated detectors rise to 15,000 and 12,000 , respectively, and Kidde wishes to continue meeting demand. Kidde's production process involves three departments: fabrication, assembly, and shipping. The relevant quantitative data on production and prices are summarized below. The company also has the option to obtain additional units from a subcontractor, who has offered to supply up to 20,000 units per month in any combination of electronic and battery-operated models, at a charge of $21.50 per unit. For this price, the subcontractor will test and ship its models directly to the retailers without using Kidde's production process. Kidde would like to determine the quantities to make and buy to maximize profit. (This is a planning model and fractional quantities are acceptable.) Sensitivity Report Variable Catis Sensitivity Report Variahle Colls Jsing only the Sensitivity Report provided answer the following uestions: a) The subcontractor was surprised to receive the order for only electronic units, and no battery-operated units. They want to know how much Kidde is willing to pay for battery-operated units so they would be included in the order. b) A review of production cost revealed that the variable cost of the battery-operated units is $19 per unit. Would that change the recommended quantity to make? Would that change the total profit? c) Fabrication capacity could be increased at a cost. What is the maximum they should be able to pay for an additional 200 hours? d) Marketing is considering increasing advertising to stimulate demand for battery-operated units. A preliminary analysis revealed that the campaign would cost $15 per unit increase in demand. What is your expert opinion on the matter? e) A problem in the supply chain will cost shipping capacity for next month to decrease by 100 hours. Management wants to know how much money they should set aside to obtain alternative shipping capacity and avoid any issues with deliveries? Explain your answer. 3) Recall the following problem and review its Sensitivity Report: A sudden increase in the demand for smoke detectors has left Kidde Safety with insufficient capacity to meet demand. The company has seen monthly demand for its electronic and battery-operated detectors rise to 15,000 and 12,000, respectively, and Kidde wishes to continue meeting demand. Kidde's production process involves three departments: fabrication, assembly, and shipping. The relevant quantitative data on production and prices are summarized below. 3) Recall the following problem and review its Sensitivity Report: A sudden increase in the demand for smoke detectors has left Kidde Safety with insufficient capacity to meet demand. The company has seen monthly demand for its electronic and battery-operated detectors rise to 15,000 and 12,000 , respectively, and Kidde wishes to continue meeting demand. Kidde's production process involves three departments: fabrication, assembly, and shipping. The relevant quantitative data on production and prices are summarized below. The company also has the option to obtain additional units from a subcontractor, who has offered to supply up to 20,000 units per month in any combination of electronic and battery-operated models, at a charge of $21.50 per unit. For this price, the subcontractor will test and ship its models directly to the retailers without using Kidde's production process. Kidde would like to determine the quantities to make and buy to maximize profit. (This is a planning model and fractional quantities are acceptable.) Sensitivity Report Variable Catis The company also has the option to obtain additional units from a subcontractor, who has offered to supply up to 20,000 units per month in any combination of electronic and battery-operated models, at a charge of $21.50 per unit. For this price, the subcontractor will test and ship its models directly to the retailers without using Kidde's production process. Kidde would like to determine the quantities to make and buy to maximize profit. (This is a planning model and fractional quantities are acceptable.) Using only the Sensitivity Report provided answer the following questions: a) The subcontractor was surprised to receive the order for only electronic units, and no battery-operated units. They want to know how much Kidde is willing to pay for battery-operated units so they would be included in the order. b) A review of production cost revealed that the variable cost of the battery-operated units is $19 per unit. Would that change the recommended quantity to make? Would that change the total profit? c) Fabrication capacity could be increased at a cost. What is the maximum they should be able to pay for an additional 200 hours? d) Marketing is considering increasing advertising to stimulate demand for battery-operated units. A preliminary analysis revealed that the campaign would cost $15 per unit increase in demand. What is your expert opinion on the matter? e) A problem in the supply chain will cost shipping capacity for next month to decrease by 100 hours. Management wants to know how much money they should set aside to obtain alternative shipping capacity and avoid any issues with deliveries? Explain your