Question: NIVERS Collar Problem 1: A screw-driven system is to be designed to raise the hatch of a furnace in a steel processing plant. The

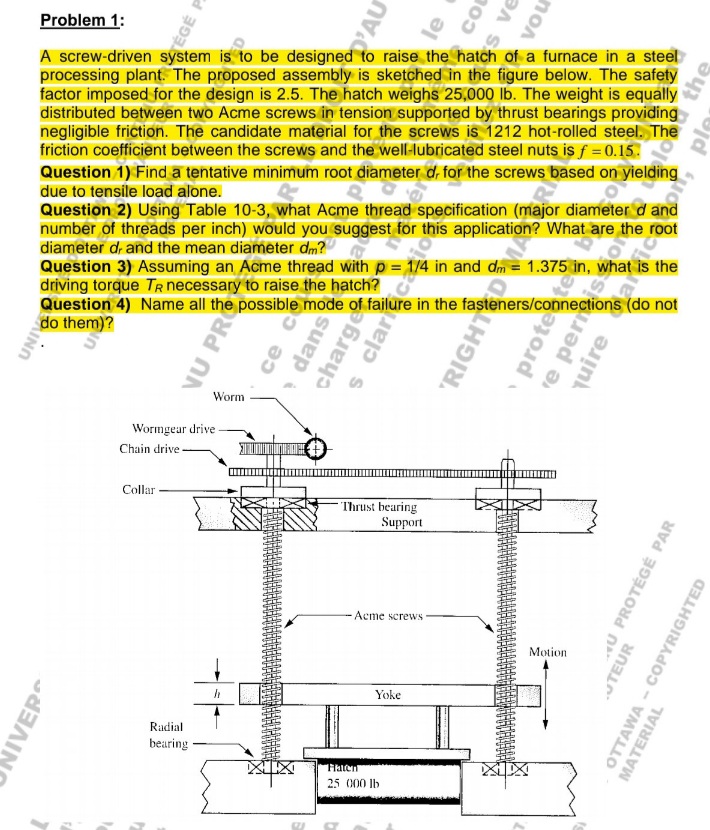

NIVERS Collar Problem 1: A screw-driven system is to be designed to raise the hatch of a furnace in a steel processing plant. The proposed assembly is sketched in the figure below. The safety factor imposed for the design is 2.5. The hatch weighs 25,000 lb. The weight is equally distributed between two Acme screws in tension supported by thrust bearings providing negligible friction. The candidate material for the screws is 1212 hot-rolled steel. The friction coefficient between the screws and the well-lubricated steel nuts is f = 0.15. Question 1) Find a tentative minimum root diameter d, for the screws based on yielding due to tensile load alone. Question 2) Using Table 10-3, what Acme thread specification (major diameter d and number of threads per inch) would you suggest for this application? What are the root diameter d, and the mean diameter dm? Question 3) Assuming an Acme thread with p = 1/4 in and dm = 1.375 in, what is the driving torque TR necessary to raise the hatch? Question 4) Name all the possible mode of failure in the fasteners/connections (do not do them)? TG P Wormgear drive Chain drive h Radial bearing Worm NU PRO h ( F ce c charge dans s clarac Thrust bearing Support Acme screws Yoke Haten 25 000 lb 200 s ve vou A Motion protestes b ve permis zon quire STEUR artic U PROTG PAR the Bid OTTAWA - COPYRIGHTED MATERIAL

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts