Question: NO NEED TO ANSWER #28. Question 24 2 pts APP Trial and Error (Chase Demand and Subcontracting) Given the following information: Period 2 3 4

NO NEED TO ANSWER #28.

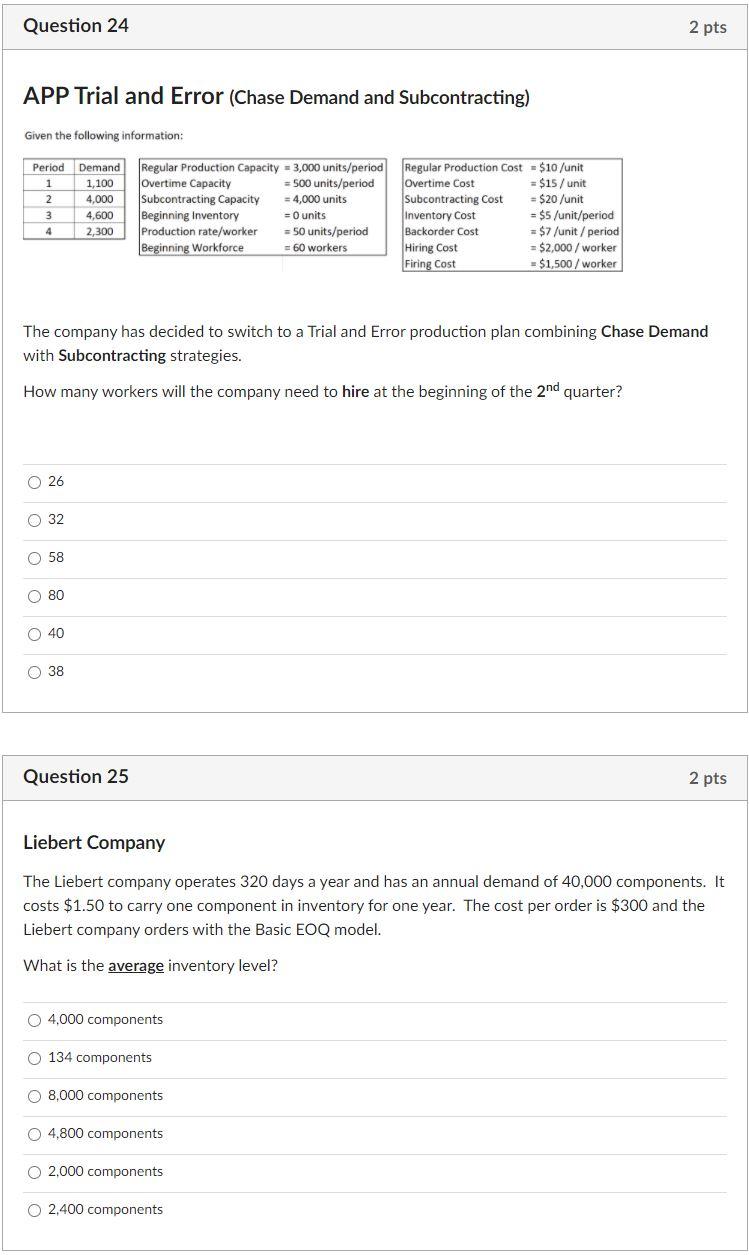

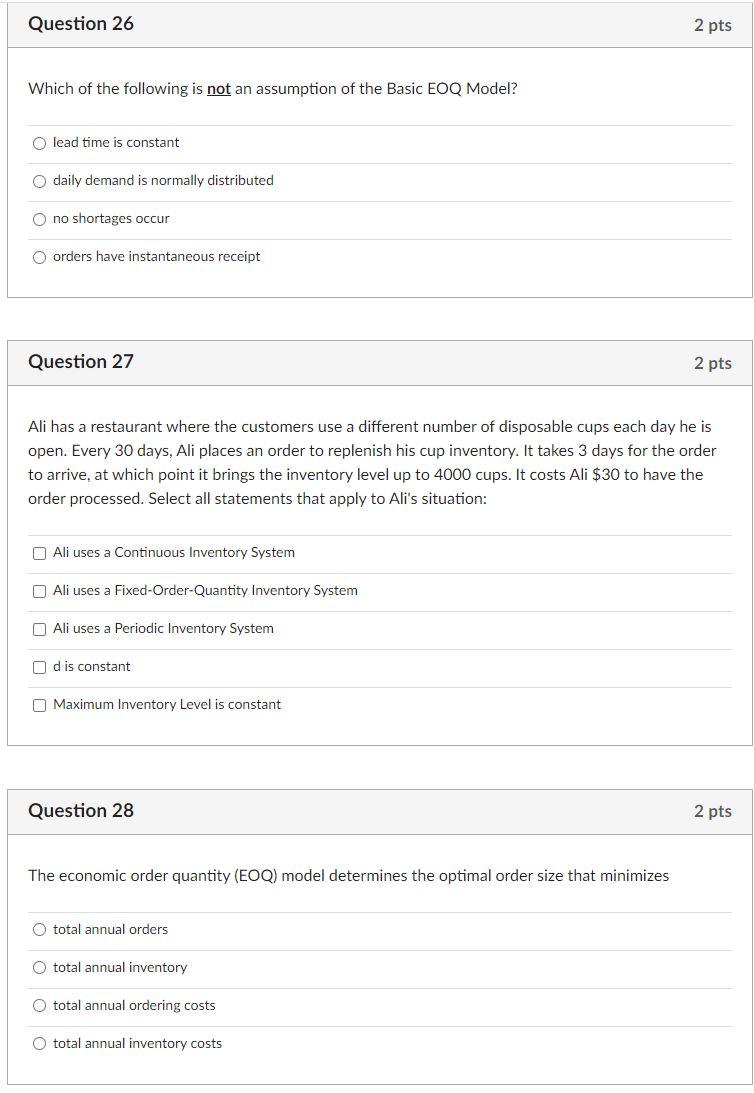

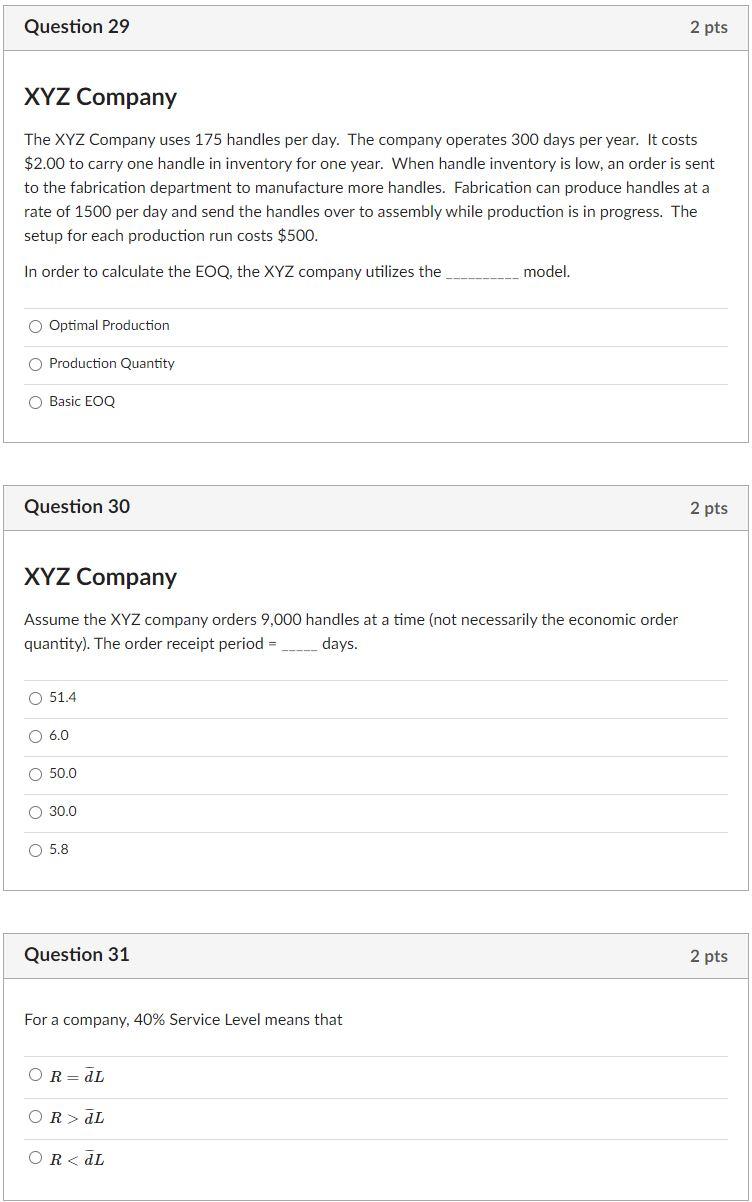

Question 24 2 pts APP Trial and Error (Chase Demand and Subcontracting) Given the following information: Period 2 3 4 Demand 1.100 4,000 4,600 2,300 Regular Production Capacity = 3,000 units/period Overtime Capacity = 500 units/period Subcontracting Capacity = 4,000 units Beginning Inventory = 0 units Production rate/worker = 50 units/period Beginning Workforce = 60 workers Regular Production Cost = $10/unit Overtime Cost = $15 / unit Subcontracting Cost = $20 /unit Inventory Cost = $5 /unit/period Backorder Cost = $7/unit/period Hiring Cost = $2,000 / worker Firing Cost = $1,500 / worker The company has decided to switch to a Trial and Error production plan combining Chase Demand with Subcontracting strategies. How many workers will the company need to hire at the beginning of the 2nd quarter? 0 26 0 32 58 0 80 040 0 38 Question 25 2 pts Liebert Company The Liebert company operates 320 days a year and has an annual demand of 40,000 components. It costs $1.50 to carry one component in inventory for one year. The cost per order is $300 and the Liebert company orders with the Basic EOQ model. What is the average inventory level? 4,000 components 134 components O 8,000 components 4,800 components 2,000 components 2,400 components Question 26 2 pts Which of the following is not an assumption of the Basic EOQ Model? O lead time is constant daily demand is normally distributed O no shortages occur O orders have instantaneous receipt Question 27 2 pts Ali has a restaurant where the customers use a different number of disposable cups each day he is open. Every 30 days, Ali places an order to replenish his cup inventory. It takes 3 days for the order to arrive, at which point it brings the inventory level up to 4000 cups. It costs Ali $30 to have the order processed. Select all statements that apply to Ali's situation: Ali uses a Continuous Inventory System Ali uses a Fixed-Order-Quantity Inventory System Ali uses a Periodic Inventory System Od is constant Maximum Inventory Level is constant Question 28 2 pts The economic order quantity (EOQ) model dete ines the optimal order size that minimi O total annual orders O total annual inventory O total annual ordering costs O total annual inventory costs Question 29 2 pts XYZ Company The XYZ Company uses 175 handles per day. The company operates 300 days per year. It costs $2.00 to carry one handle in inventory for one year. When handle inventory is low, an order is sent to the fabrication department to manufacture more handles. Fabrication can produce handles at a rate of 1500 per day and send the handles over to assembly while production is in progress. The setup for each production run costs $500. In order to calculate the EOQ, the XYZ company utilizes the model. Optimal Production O Production Quantity Basic EOQ Question 30 2 pts XYZ Company Assume the XYZ company orders 9,000 handles at a time (not necessarily the economic order quantity). The order receipt period - days. O 51.4 0 6.0 O 50.0 O 30.0 O 5.8 Question 31 2 pts For a company, 40% Service Level means that OR=dL OR > IL ORStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock