Question: No stopping this train! Background: Replacing outdated trains in South Africa Trains are at the core of the modernisation program of the Passenger Rail Agency

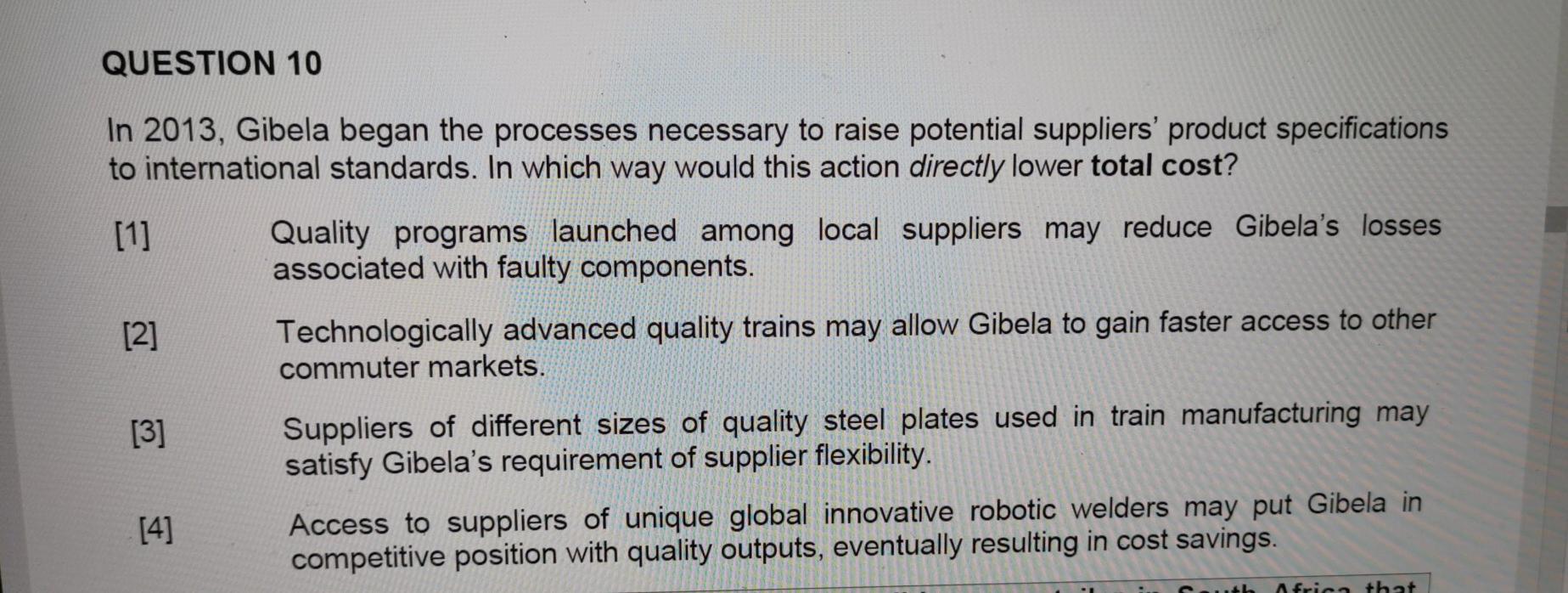

No stopping this train! Background: Replacing outdated trains in South Africa Trains are at the core of the modernisation program of the Passenger Rail Agency of South Africa (PRASA) to deliver improved passenger services to the country's commuters. In one of South Africa's largest-ever infrastructure projects, Gibela Rail Transport Consortium contracted with PRASA for a train upgrade replacement programme serving as a catalyst for transformation in South Africa, which includes stringent economic development commitments. Gibela is a South African joint venture (JV) which brings together Alstom (a French train manufacturer) and local empowered businesses. Training and development are fundamental to Gibela's commitments as they work to build and enhance rail technology skills amongst employees, suppliers and students. Following Gibela's tracks The road to delivering the first train at the end of 2018 required focused planning, negotiation and commitment, as can be seen in the following milestone events. 2013-2014 Milestone 1: Gibela's vision to develop local supply chains provided the local component and service suppliers with an opportunity to see, first-hand, how their products would be contributing to the creation of fully operational trains. Welcoming the suppliers, Gibela's CEO Marc Granger said that, in just two years, Gibela's journey in delivering the next generation of trains to South Africa's rail-commuter public had gained momentum on all fronts and in particular, in the sourcing and supply of local equipment and components of a standard that was meeting Gibela's high quality and other standard demands. In Granger's address to the suppliers he added: By producing quality components such as these, local suppliers will, in addition to being able to service Gibela and the South African rail sector as a whole, be able to compete in global markets, opening up the real potential for significant exports and resultant foreign exchange earnings for South Africa. We are starting to make substantial progress in rejuvenating our local rail manufacturing industry's capabilities and capacity." While making it clear that his list was not exclusive, Granger flagged a broad range of South African- made components visible inside and outside each train, and other equally important components not visible to passengers, such as batteries, heating and braking systems. Although there had been no contractual obligations for local content on the 20 Brazilian-built trains, Gibela took a strategic decision to get a head-start to ensure that local suppliers are well prepared in terms of technical capability, capacity and investment) for an intensive manufacturing programme adhering to stringent standards of quality and tight delivery schedules. For each train that had already been built in Brazil , 22% of procurement spend was on components sourced from South African suppliers of which a large percentage was on interiors, energy and sheet metal work domains. Contributing to the success of the South African suppliers had been the technical advice and assistance provided to them by Gibela itself and commitment, as can be seen in the following milestone events. 2013-2014 Milestone 1: Gibela's vision to develop local supply chains In October 2013, Gibela was awarded a contract by PRASA to manufacture and replace South Africa's outdated trains and deliver 600 new passenger trains into the South African rail network within 10 years. This project also involved the construction of a manufacturing facility in South Africa. In 2014, Gibela preselected nearly 100 local companies as possible component and service suppliers to show their commitment to fulfilling local content requirements during the servicing of the R51-billion rolling stock* contract. The company targeted 70% local content in its components and services to revitalise the South African economy and develop local supply chains. At that stage, before negotiations even took place, eleven letters of intent for the provision of steel, cables, lights, interiors, connectors, and insulation had been signed, while four contracts with local suppliers had already been in place. In some cases, Gibela even began the processes necessary to raise the potential suppliers' product specifications to international standards. 2016 Milestone 2: Gibela's progress towards meeting the local content target standards. 2016 Milestone 2: Gibela's progress towards meeting the local content target By 2016, Gibela had already initiated the construction of a state-of-the-art local factory where 580 of the 600 trains were to be built by trained and skilled South Africans using South African inputs. At that stage, the factory was scheduled to deliver its first train by the end of 2018 and, thereafter, to deliver five completed trains each month for 10 years to PRASA. Prior to 2016, 20 of the 600 trains had been built at Alstom's Brazilian plant. All components for the first 20 trains had been made in South Africa, using South African materials, and had been shipped to Brazil. During a site visit in June 2016, the first 32 South African suppliers to provide local content for the new passenger trains being built by Gibela were welcomed to PRASA's Wolmerton depot to view the manufacturing of the first five X'Trapolis Mega** trains to be completed. This visit 52 Although there had been no contractual obligations for local content on the 20 Brazilian-built trains, Gibela took a strategic decision to get a head-start to ensure that local suppliers are well prepared (in terms of technical capability, capacity and investment) for an intensive manufacturing programme adhering to stringent standards of quality and tight delivery schedules. For each train that had already been built in Brazil, 22% of procurement spend was on components sourced from South African suppliers of which a large percentage was on interiors, energy and sheet metal work domains. Contributing to the success of the South African suppliers had been the technical advice and assistance provided to them by Gibela itself as part of efforts to develop a robust and sustainable South African supplier base. The following examples of Siyahamba Engineering and LED Lighting SA proved their success in this regard. Siyahamba Engineering had been responsible for the supply of cabin doors and partition walls for the new trains. CEO Julius Motshopi said: Gibela brought in a specialist from the UK to work with us to help us industrialise and organise ourselves. We have gone through a steep learning curve and developed a good working relationship in the process. LED Lighting SA, a Cape Town-based medium-sized company, supplied Gibela with one of the world's first set of exterior LED lights to comply with international rail standards. CEO Andrew Glenday commented: There's much more of a buzz in South Africa around the rail transportation and I believe that well-structured investment in our local rail business will be repaid many times over through export, employment, skills development and even intangibly in national pride. I am proud of the offices and factory we have set up. They are as well established as any factory in the United States or Europe; we're making world-class products

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock