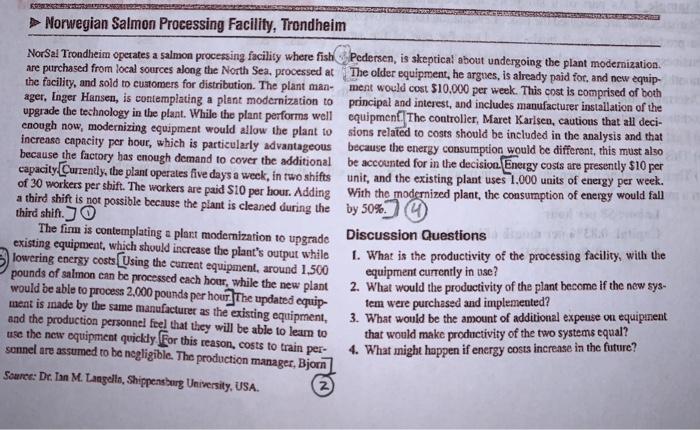

> Norwegian Salmon Processing Facility, Trondheim NorSal Trondheim operates a salmon processing facility where fish Pedersen, is skeptical about undergoing the plant modernization. are purchased from local sources along the North Sea, processed at The older equipment, he argues, is already paid for, and new equip- the facility, and sold to customers for distribution. The plant man- ment would cost $10.000 per week. This cost is comprised of both ager, Inger Hansen, is contemplating a plant modernization to principal and interest, and includes manufacturer installation of the upgrade the technology in the plant. While the plant performs well equipment. The controlier, Maret Karlsen, cautious that all deci- enough now, modernizing equipment would allow the plant tosions related to costs should be included in the analysis and that increase capacity per bour, which is particularly advantageous because the energy consumption would be different, this must also because the factory has enough demand to cover the additional be accounted for in the decision Energy costs are presently $10 per capacity. Currently, the plant operates five days a week, in two shifts unit, and the existing plant uses 7.000 units of energy per week. of 30 workers per shift. The workers are paid S10 per hour. Adding with the modernized plant, the consumption of energy would fall a third shift is not possible because the plant is cleaned during the by 50%. third shin. Jo The firm is contemplating a plant modernization to upgrade Discussion Questions existing equipment, which should increase the plant's output while lowering energy costs Using the current equipment, around 1.500 1. What is the productivity of the processing facility, with the equipment currently in tis? pounds of salmon can be processed each hour, while the new plant 2. What would the productivity of the plant become if the new sys- would be able to process 2.000 pounds per hour. The updated equip- tem were purchased and implemented? ment is made by the same manufacturer as the existing equipment. 3. What would be the amount of additional expense on equipment and the production personnel feel that they will be able to leam to use the new equipment quickly For this reason, costs to train per- that would make productivity of the two systems equal? sonnel are assumed to be negligible. The production manager, Bjorn 4. What snight happen if energy costs increase in the future? Source: De Tan M. Langeilo, Shippensburg University, USA. 2