Question: not sure how to fill out the A3 document. please explain and show all work SCENARIO The ABC Construction Company operates two facilities in neighboring

not sure how to fill out the A3 document. please explain and show all work

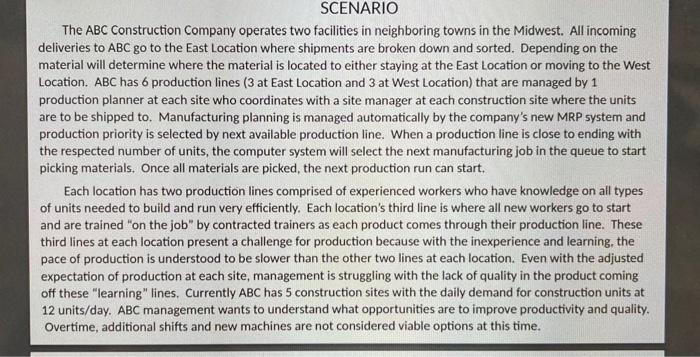

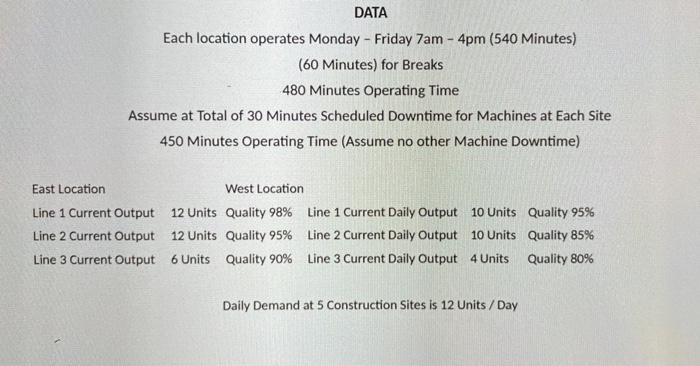

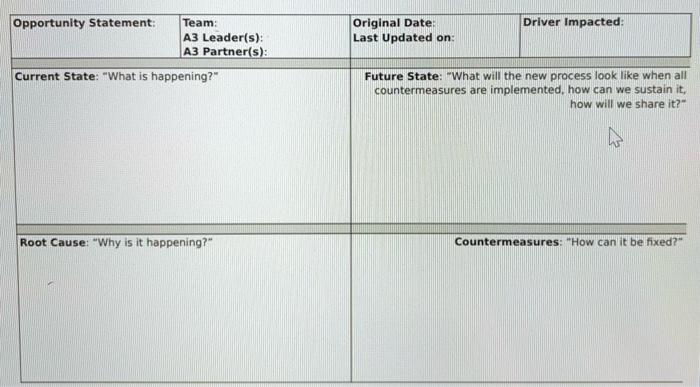

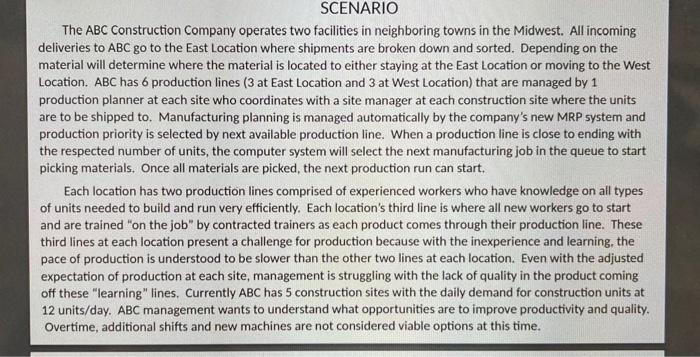

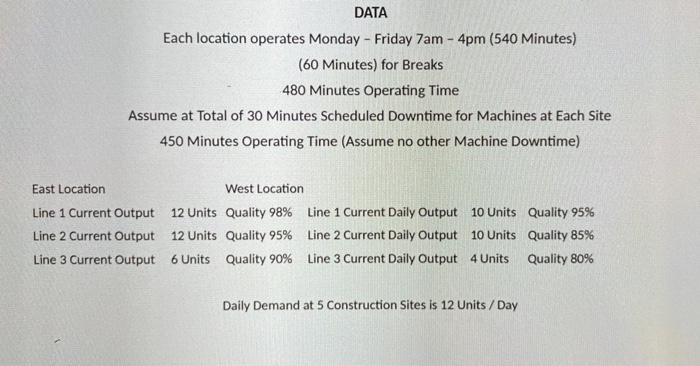

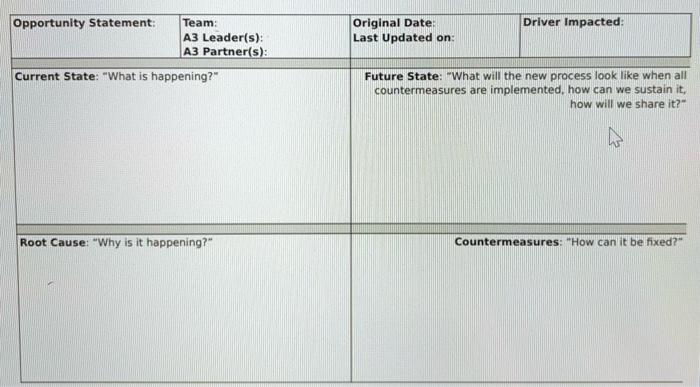

SCENARIO The ABC Construction Company operates two facilities in neighboring towns in the Midwest. All incoming deliveries to ABC go to the East Location where shipments are broken down and sorted. Depending on the material will determine where the material is located to either staying at the East Location or moving to the West Location. ABC has 6 production lines (3 at East Location and 3 at West Location) that are managed by 1 production planner at each site who coordinates with a site manager at each construction site where the units are to be shipped to. Manufacturing planning is managed automatically by the company's new MRP system and production priority is selected by next available production line. When a production line is close to ending with the respected number of units, the computer system will select the next manufacturing job in the queue to start picking materials. Once all materials are picked, the next production run can start. Each location has two production lines comprised of experienced workers who have knowledge on all types of units needed to build and run very efficiently. Each location's third line is where all new workers go to start and are trained "on the job" by contracted trainers as each product comes through their production line. These third lines at each location present a challenge for production because with the inexperience and learning, the pace of production is understood to be slower than the other two lines at each location. Even with the adjusted expectation of production at each site, management is struggling with the lack of quality in the product coming off these "learning" lines. Currently ABC has 5 construction sites with the daily demand for construction units at 12 units/day. ABC management wants to understand what opportunities are to improve productivity and quality. Overtime, additional shifts and new machines are not considered viable options at this time. DATA Each location operates Monday - Friday 7am - 4pm (540 Minutes) (60 Minutes) for Breaks 480 Minutes Operating Time Assume at Total of 30 Minutes Scheduled Downtime for Machines at Each Site 450 Minutes Operating Time (Assume no other Machine Downtime) East Location West Location Line 1 Current Output 12 Units Quality 98% Line 1 Current Daily Output 10 Units Quality 95% Line 2 Current Output 12 Units Quality 95% Line 2 Current Daily Output 10 Units Quality 85% Line 3 Current Output 6 Units Quality 90% Line 3 Current Daily Output 4 Units Quality 80% Daily Demand at 5 Construction Sites is 12 Units / Day Driver Impacted: Original Date: Last Updated on: Opportunity Statement: Team: A3 Leader(s): A3 Partner(s): Current State: "What is happening?" Future State: "What will the new process look like when all countermeasures are implemented, how can we sustain it, how will we share it?" Root Cause: "Why is it happening?" Countermeasures: "How can it be fixed

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock