Question: Note: Can you please make an actual VSM ( drawing ) with boxes and all the details? A company Alpha produces X material bags with

Note: Can you please make an actual VSM drawing with boxes and all the details?

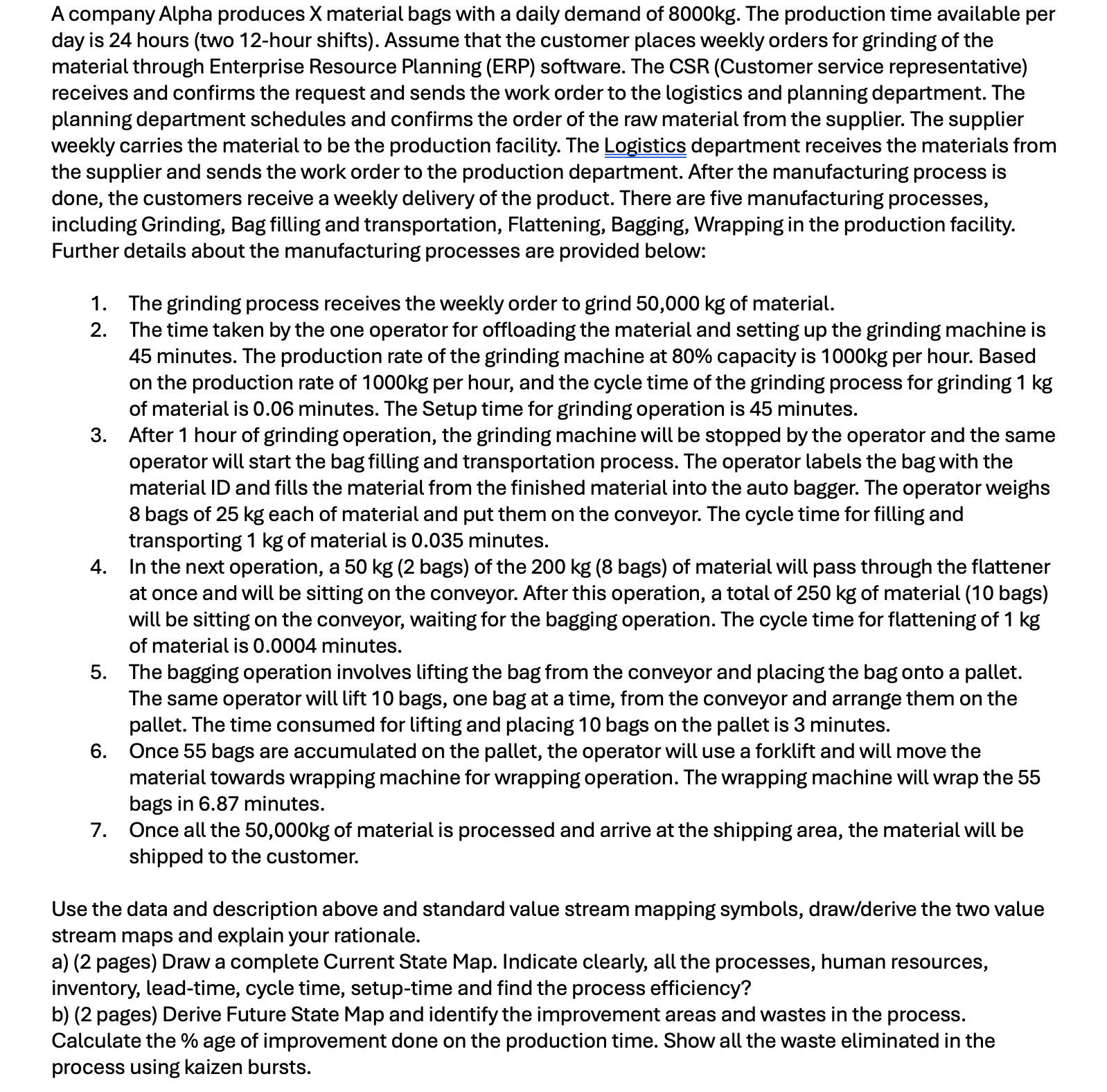

A company Alpha produces X material bags with a daily demand of The production time available per

day is hours two hour shifts Assume that the customer places weekly orders for grinding of the

material through Enterprise Resource Planning ERP software. The CSR Customer service representative

receives and confirms the request and sends the work order to the logistics and planning department. The

planning department schedules and confirms the order of the raw material from the supplier. The supplier

weekly carries the material to be the production facility. The Logistics department receives the materials from

the supplier and sends the work order to the production department. After the manufacturing process is

done, the customers receive a weekly delivery of the product. There are five manufacturing processes,

including Grinding, Bag filling and transportation, Flattening, Bagging, Wrapping in the production facility.

Further details about the manufacturing processes are provided below:

The grinding process receives the weekly order to grind of material.

The time taken by the one operator for offloading the material and setting up the grinding machine is

minutes. The production rate of the grinding machine at capacity is per hour. Based

on the production rate of per hour, and the cycle time of the grinding process for grinding

of material is minutes. The Setup time for grinding operation is minutes.

After hour of grinding operation, the grinding machine will be stopped by the operator and the same

operator will start the bag filling and transportation process. The operator labels the bag with the

material ID and fills the material from the finished material into the auto bagger. The operator weighs

bags of each of material and put them on the conveyor. The cycle time for filling and

transporting of material is minutes.

In the next operation, a bags of the bags of material will pass through the flattener

at once and will be sitting on the conveyor. After this operation, a total of of material bags

will be sitting on the conveyor, waiting for the bagging operation. The cycle time for flattening of

of material is minutes.

The bagging operation involves lifting the bag from the conveyor and placing the bag onto a pallet.

The same operator will lift bags, one bag at a time, from the conveyor and arrange them on the

pallet. The time consumed for lifting and placing bags on the pallet is minutes.

Once bags are accumulated on the pallet, the operator will use a forklift and will move the

material towards wrapping machine for wrapping operation. The wrapping machine will wrap the

bags in minutes.

Once all the of material is processed and arrive at the shipping area, the material will be

shipped to the customer.

Use the data and description above and standard value stream mapping symbols, drawderive the two value

stream maps and explain your rationale.

a pages Draw a complete Current State Map. Indicate clearly, all the processes, human resources,

inventory, leadtime, cycle time, setuptime and find the process efficiency?

b pages Derive Future State Map and identify the improvement areas and wastes in the process.

Calculate the age of improvement done on the production time. Show all the waste eliminated in the

process using kaizen bursts.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock