Question: Note: Please solve both parts(a & c). I will upvote you lifetime Exercise 4: Material Requirements Planning (MRP-I) (35 Marks) The planning of a production

Note: Please solve both parts(a & c). I will upvote you lifetime

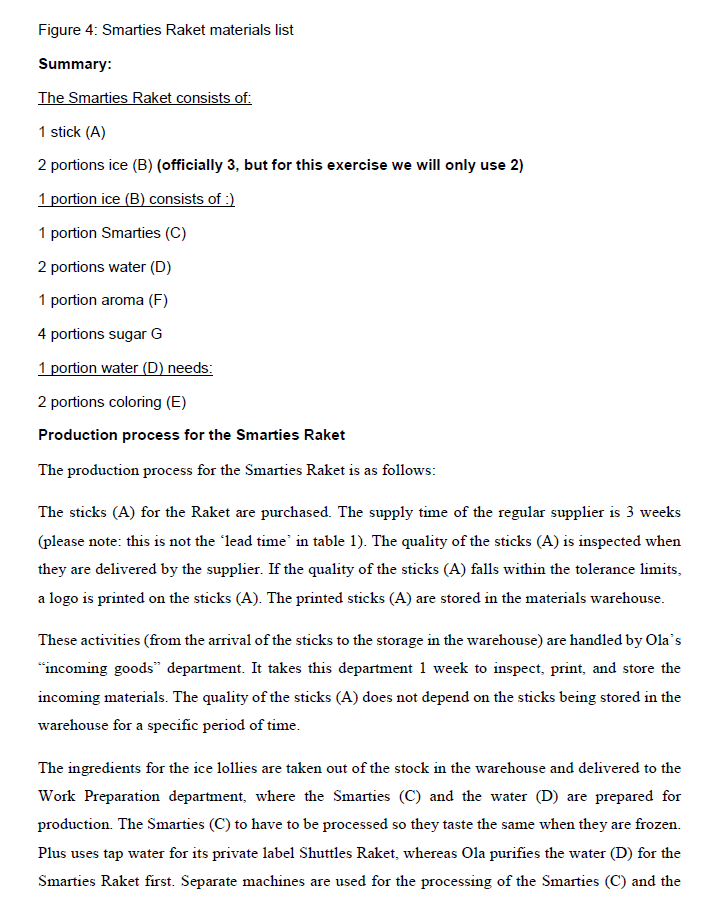

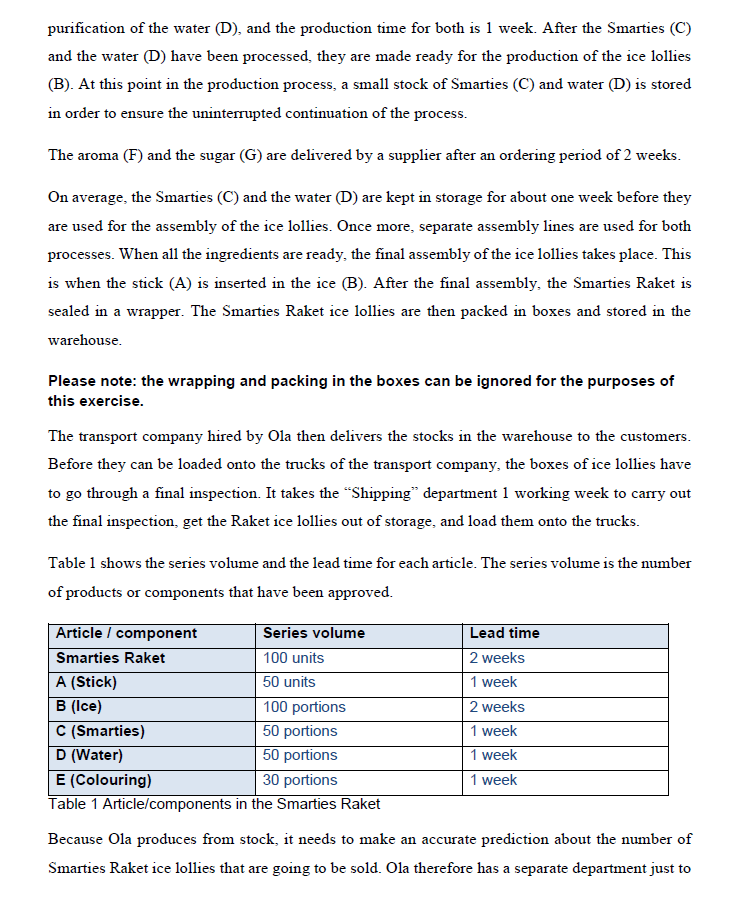

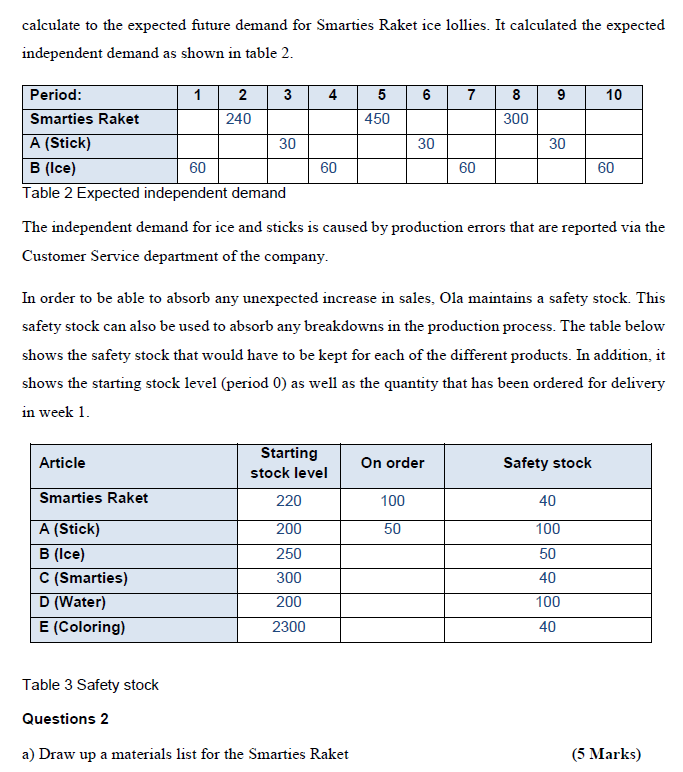

Exercise 4: Material Requirements Planning (MRP-I) (35 Marks) The planning of a production process is a very important subject in the subsystem of material management. In a lot of companies, the production process has become so complex that the planning can no longer worked out manually. The use of modern technology makes it possible to manage the production process in a controlled way. There are a wide range of software packages available for logistical planning. For production planning, many of the software packages are based on the MRP system. It is therefore essential for a logistical planner to be familiar with the concept behind MRP and to be able to solve simple MRP problems. That is what we are going to do in this exercise. The exercise will look at the production process of Ola, a company that makes ice lollies and ice creams. Ola makes all types of different ice lollies and ice creams, including the Raket (rocket), the Schatkist (Treasure Chest), and the Twister. This exercise will look specifically at the Raket ice lolly of Ola. This product has been on the market for many years, and is now declining in popularity. The Raket has therefore been rebranded by adding Smarties to the ice lolly. It is going to be relaunched under the name Smarties Raket. The relaunch will be promoted with lots of marketing stunts in order to make the ice lolly popular again. SMASTIES Figure 1: Raket Figure 2: Smarties Principles of Logistics BUSS-B - 2001 - Spring 2021 - CW 2 (Assignment) - QP In recent years, there have been several marketing campaigns to launch new ice creams. There have been numerous advertisements for the Raket. For example: OLA I love the Netherlands EN IK VAN JOU! And I love you NIET 20 SERIEUS! Figure 3: Raket advertisement The advertisements for the Raket did not have the desired effect. A decision was therefore taken to launch the Smarties Raket on the market. B Ice C Smarties D Water E Coloring F Aroma G Sugar A Stick Figure 4: Smarties Raket materials list Summary: The Smarties Raket consists of: 1 stick (A) 2 portions ice (B) (officially 3, but for this exercise we will only use 2) 1 portion ice (B) consists of :) 1 portion Smarties (C) 2 portions water (D) 1 portion aroma (F) 4 portions sugar G 1 portion water (D) needs: 2 portions coloring (E) Production process for the Smarties Raket The production process for the Smarties Raket is as follows: The sticks (A) for the Raket are purchased. The supply time of the regular supplier is 3 weeks (please note: this is not the 'lead time in table 1). The quality of the sticks (A) is inspected when they are delivered by the supplier. If the quality of the sticks (A) falls within the tolerance limits, a logo is printed on the sticks (A). The printed sticks (A) are stored in the materials warehouse. These activities (from the arrival of the sticks to the storage in the warehouse) are handled by Ola's "incoming goods department. It takes this department 1 week to inspect, print, and store the incoming materials. The quality of the sticks (A) does not depend on the sticks being stored in the warehouse for a specific period of time. The ingredients for the ice lollies are taken out of the stock in the warehouse and delivered to the Work Preparation department, where the Smarties (C) and the water (D) are prepared for production. The Smarties (C) to have to be processed so they taste the same when they are frozen. Plus uses tap water for its private label Shuttles Raket, whereas Ola purifies the water (D) for the Smarties Raket first. Separate machines are used for the processing of the Smarties (C) and the purification of the water (D), and the production time for both is 1 week. After the Smarties (C) and the water (D) have been processed, they are made ready for the production of the ice lollies (B). At this point in the production process, a small stock of Smarties (C) and water (D) is stored in order to ensure the uninterrupted continuation of the process. The aroma (F) and the sugar (G) are delivered by a supplier after an ordering period of 2 weeks. On average, the Smarties (C) and the water (D) are kept in storage for about one week before they are used for the assembly of the ice lollies. Once more, separate assembly lines are used for both processes. When all the ingredients are ready, the final assembly of the ice lollies takes place. This is when the stick (A) is inserted in the ice (B). After the final assembly, the Smarties Raket is sealed in a wrapper. The Smarties Raket ice lollies are then packed in boxes and stored in the warehouse. Please note: the wrapping and packing in the boxes can be ignored for the purposes of this exercise. The transport company hired by Ola then delivers the stocks in the warehouse to the customers. Before they can be loaded onto the trucks of the transport company, the boxes of ice lollies have to go through a final inspection. It takes the Shipping department 1 working week to carry out the final inspection, get the Raket ice lollies out of storage, and load them onto the trucks. Table 1 shows the series volume and the lead time for each article. The series volume is the number of products or components that have been approved. Article / component Series volume Lead time Smarties Raket 100 units 2 weeks 1 week 2 weeks 1 week A (Stick) 50 units B (Ice) 100 portions C (Smarties) 50 portions D (Water) 50 portions E (Colouring) 30 portions Table 1 Article/components in the Smarties Raket 1 week 1 week Because Ola produces from stock, it needs to make an accurate prediction about the number of Smarties Raket ice lollies that are going to be sold. Ola therefore has a separate department just to calculate to the expected future demand for Smarties Raket ice lollies. It calculated the expected independent demand as shown in table 2. Period: 1 | 2 | 3 4 5 6 7 8 9 10 Smarties Raket 240 450 300 30 30 30 A (Stick) B (Ice) Table 2 Expected independent demand 60 60 60 60 The independent demand for ice and sticks is caused by production errors that are reported via the Customer Service department of the company. In order to be able to absorb any unexpected increase in sales. Ola maintains a safety stock. This safety stock can also be used to absorb any breakdowns in the production process. The table below shows the safety stock that would have to be kept for each of the different products. In addition, it shows the starting stock level (period () as well as the quantity that has been ordered for delivery in week 1. Article Starting stock level On order Safety stock Smarties Raket 220 100 40 200 50 100 250 50 A (Stick) B (Ice) C (Smarties) D (Water) E (Coloring) 300 40 200 100 2300 40 Table 3 Safety stock Questions 2 a) Draw up a materials list for the Smarties Raket (5 Marks) c) Make an MRP-1 planning schedule for the different articles and components. Use the MRP table in Appendix 1 for this. Only do this for the Smarties Raket and articles A to EStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock