Question: Note: show calculation steps for Question 1 and 2. 1. Lead time for one of your fastest-moving products is 25 days. Demand during this period

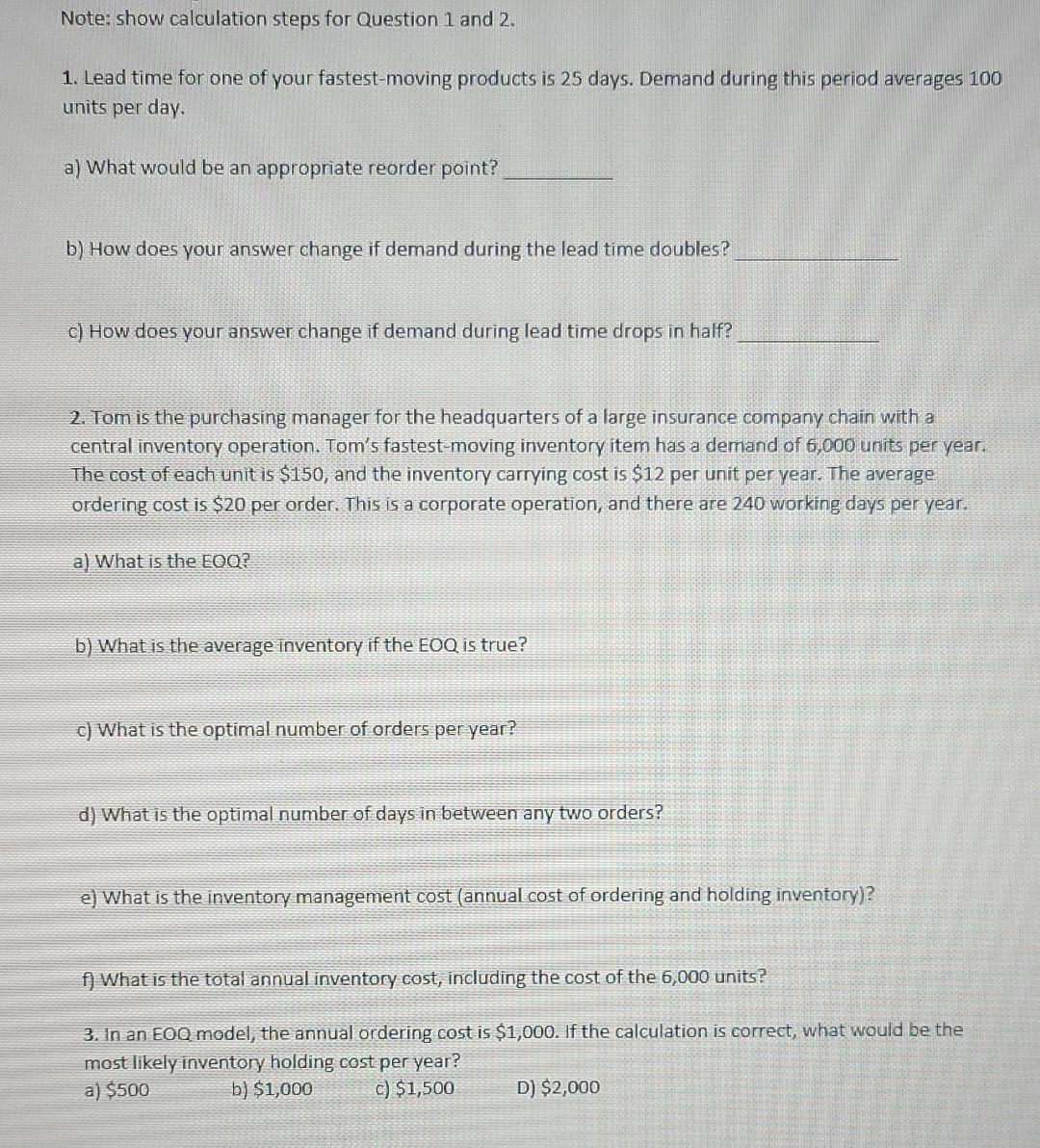

Note: show calculation steps for Question 1 and 2. 1. Lead time for one of your fastest-moving products is 25 days. Demand during this period averages 100 units per day a) What would be an appropriate reorder point? b) How does your answer change if demand during the lead time doubles? c) How does your answer change if demand during lead time drops in half? 2. Tom is the purchasing manager for the headquarters of a large insurance company chain with a central inventory operation. Tom's fastest-moving inventory item has a demand of 6,000 units per year. The cost of each unit is $150, and the inventory carrying cost is $12 per unit per year. The average ordering cost is $20 per order. This is a corporate operation, and there are 240 working days per year. a) What is the EOQ? b) What is the average inventory if the EOQ is true? c) What is the optimal number of orders per year? d) What is the optimal number of days in between any two orders? e) What is the inventory management cost (annual cost of ordering and holding inventory)? f) What is the total annual inventory cost, including the cost of the 6,000 units? 3. In an EOQ model, the annual ordering cost is $1,000. If the calculation is correct, what would be the most likely inventory holding cost per year? a) $500 b) $1,000 C) $1,500 D) $2,000

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock