Question: Note: This problem needs to be solved in Excel using Solver. Please explain how to set it up in excel ( Matrix method ) and

Note: This problem needs to be solved in Excel using Solver. Please explain how to set it up in excel Matrix method and what the decision variables are, what the objective is and the constraints. Then, start it in Excel and use solver to finish solving the problem. Thanks.

Edison's Equipment

This problem is based upon MBA graduate Sam E consulting problem. All names and contexts have been changed to protect those covered under US Code Title legislation.

Due to the plethora of companies involved in the medical equipment area, Edison's Equipment needs to consolidate its warehouses to stay profitable. Warehouses S S and S are to be closed, and their main SKU groups of products redistributed to the other active warehouses mathrmSmathrm~Smathrm~Smathrm~Smathrm~Smathrm~Smathrm~S

The two main SKU groups PACKA and PACKB. Each SKU Group uses up a certain amount of warehouse space PACKA uses space units per unit of product and PACKB uses space unit per unit of product.

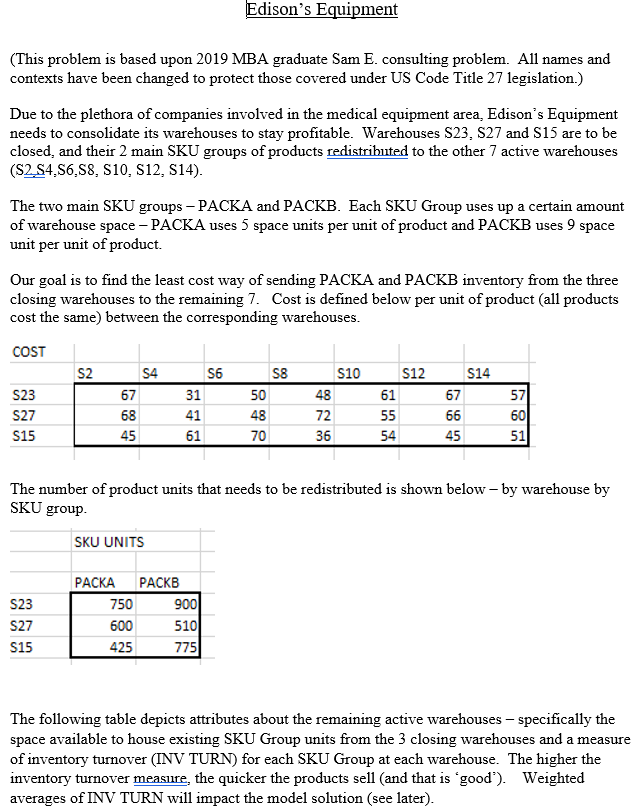

Our goal is to find the least cost way of sending PACKA and PACKB inventory from the three closing warehouses to the remaining Cost is defined below per unit of product all products cost the same between the corresponding warehouses.

The number of product units that needs to be redistributed is shown below by warehouse by SKU group.

The following table depicts attributes about the remaining active warehouses specifically the space available to house existing SKU Group units from the closing warehouses and a measure of inventory turnover INV TURN for each SKU Group at each warehouse. The higher the inventory turnover measure, the quicker the products sell and that is 'good' Weighted averages of INV TURN will impact the model solution see later

Create an LP model that will determine how to send the two kinds of SKU units from S S and S to the remaining active warehouses. Cost should be minimized. Your model must be very explicit in its specifications.

Other aspects of your model:

All SKU units must be sent. No more, no less.

The space of arriving units at an active warehouse is constrained by the space available. Refer back to underlineunderlinetext rd paragraph for how much space each SKU group requires.

Also, at least of the space requirements at each active warehouse must be used by SKU Group arrivals. This is a de facto 'balancing' constraint.

To make sure products are sent to where they are more likely to be sold, the INV TURN of arriving units at each warehouse must average at least per unit.

Using warehouse space as the relevant units, limit the combined warehouse space units of PACKA and PACKB equipment units sent from any one closing warehouse to any one active warehouse to no more than Again, this is in units of warehouse space.

At the end, make sure integer units are sent. But not until the end.

Note: Incorrect decision variable specification will limit available checkpoint 'points' to no more than of the possible total points that can be earned.

Version I reserve the right to modify the problem description as necessary up until the due date.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock