Question: % O 5 1 0 ( HW 5 _ v 1 _ single level subprograms G 5 4 G 2 0 G 9 0 G

OHW vsingle level subprograms

G G G G G G G G

G X Y

T M

G X Y

G Z S M H

G Z F M

G G X Y F D

G Xmathrm Y Rmathrm Z

I J Z

IJJ Z

I J

XYZR

G G Z M

G Z M

T M

G X Y Z

G X Y

G Z S M

G Z F M

Blank P L

G G Z

G X Y R

G X Y G H Z S M

M P L

G G Z M

G G X Y Z

G G Z M

G X Y

M

for Vericut only; remove to run on a machine

for Vericut only; remove to run on a machine

Ofor Vericut only; replace O with N to run on a machine

subprogram for cutting the x pocket

starts at the center of the pocket

N G G X

N G I J Z Fhelical ramp

N G G X Ymathrm F D

N G Xmathrm Y R

G X

G R

G

G Xmathrm Ymathrm R

G

G R

G Y

G Xmathrm Ymathrm R

G X

G Xmathrm Ymathrm R

G G Xmathrm Y

for Vericut only; remove to run on a machineN G G Y F D

N G R

G R

G

G Xmathrm Ymathrm R

N G Xmathrm Ymathrm R

N G G X

N G D X

N G X Y R

G Xmathrm Ymathrm R

G

G R

N G R

N G G Y

M

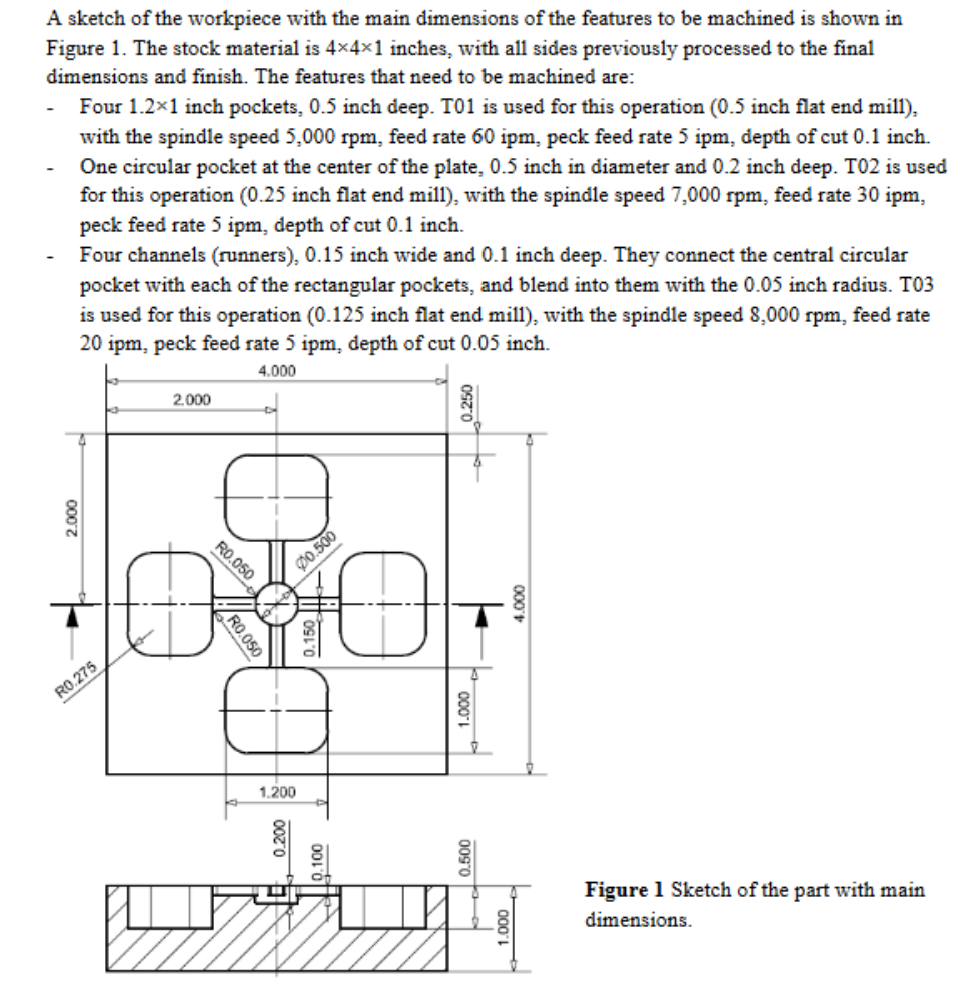

A sketch of the workpiece with the main dimensions of the features to be machined is shown in

Figure The stock material is inches, with all sides previously processed to the final

dimensions and finish. The features that need to be machined are:

Four inch pockets, inch deep. T is used for this operation inch flat end mill

with the spindle speed feed rate ipm peck feed rate ipm depth of cut inch

One circular pocket at the center of the plate, inch in diameter and inch deep. T is used

for this operation inch flat end mill with the spindle speed feed rate ipm

peck feed rate ipm depth of cut inch.

Four channels runners inch wide and inch deep. They connect the central circular

pocket with each of the rectangular pockets, and blend into them with the inch radius. T

is used for this operation inch flat end mill with the spindle speed feed rate

ipm peck feed rate ipm depth of cut inch.

Figure Sketch of the part with main

dimensions.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock