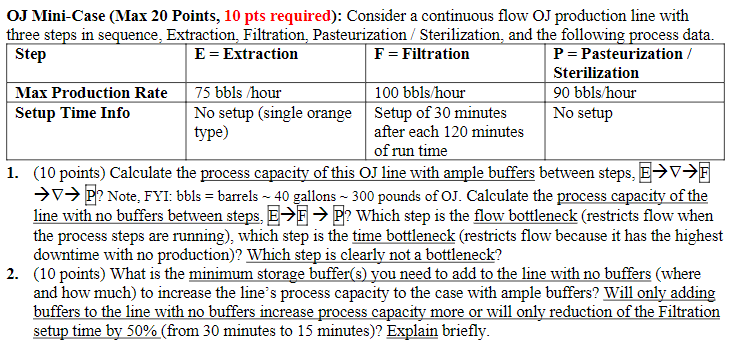

Question: OJ Mini-Case (Max 20 Points, 10 pts required): Consider a continuous flow OJ production line with three steps in sequence, Extraction, Filtration, Pasteurization / Sterilization,

OJ Mini-Case (Max 20 Points, 10 pts required): Consider a continuous flow OJ production line with three steps in sequence, Extraction, Filtration, Pasteurization / Sterilization, and the following process data. 1. (10 points) Calculate the process capacity of this OJ line with ample buffers between steps, EF P? Note, FYI: bbls = barrels 40 gallons 300 pounds of OJ. Calculate the process capacity of the line with no buffers between steps, EFP ? Which step is the flow bottleneck (restricts flow when the process steps are running), which step is the time bottleneck (restricts flow because it has the highest downtime with no production)? Which step is clearly not a bottleneck? 2. (10 points) What is the minimum storage buffer(s) you need to add to the line with no buffers (where and how much) to increase the line's process capacity to the case with ample buffers? Will only adding buffers to the line with no buffers increase process capacity more or will only reduction of the Filtration setup time by 50% (from 30 minutes to 15 minutes)? Explain briefly

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts