Question: only need help understanding part e! thank you As part of a major plant renovation project, the industrial engineering department has been asked to balance

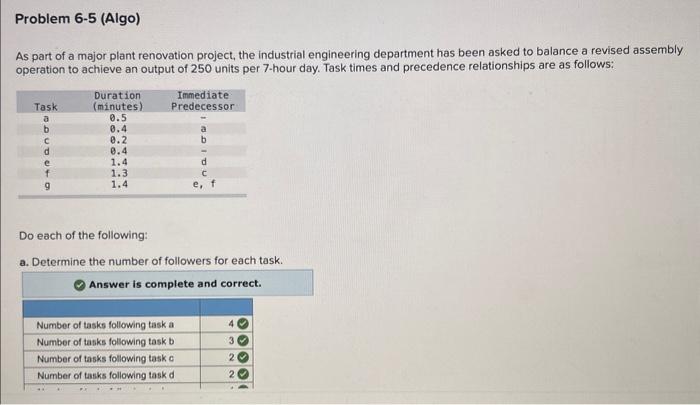

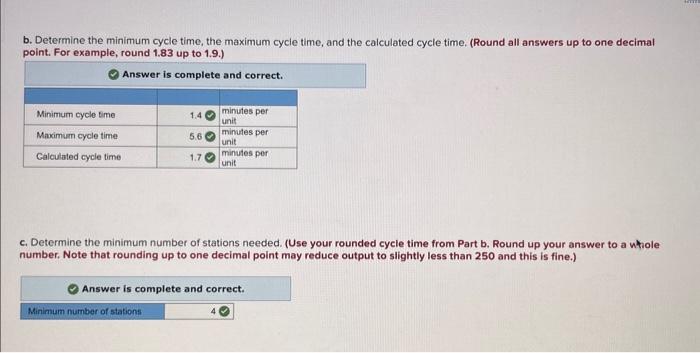

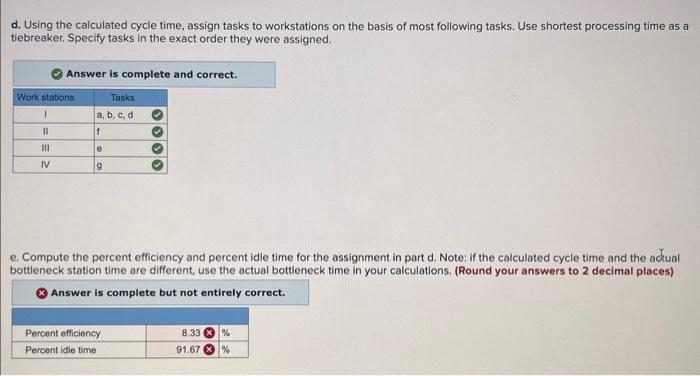

As part of a major plant renovation project, the industrial engineering department has been asked to balance a revised assembly operation to achieve an output of 250 units per 7 -hour day. Task times and precedence relationships are as follows: Do each of the following: a. Determine the number of followers for each task. Answer is complete and correct. b. Determine the minimum cycle time, the maximum cycle time, and the calculated cycle time. (Round all answers up to one decimal point. For example, round 1.83 up to 1.9.) c. Determine the minimum number of stations needed. (Use your rounded cycle time from Part b. Round up your answer to a utiole number. Note that rounding up to one decimal point may reduce output to slightly less than 250 and this is fine.) d. Using the calculated cycle time, assign tasks to workstations on the basis of most following tasks. Use shortest processing time as a tiebreaker. Specify tasks in the exact order they were assigned. Answer is complete and correct. e. Compute the percent efficiency and percent idle time for the assignment in part d. Note: if the calculated cycle time and the actual bottleneck station time are different, use the actual bottleneck time in your calculations. (Round your answers to 2 decimal places) Answer is complete but not entirely correct. As part of a major plant renovation project, the industrial engineering department has been asked to balance a revised assembly operation to achieve an output of 250 units per 7 -hour day. Task times and precedence relationships are as follows: Do each of the following: a. Determine the number of followers for each task. Answer is complete and correct. b. Determine the minimum cycle time, the maximum cycle time, and the calculated cycle time. (Round all answers up to one decimal point. For example, round 1.83 up to 1.9.) c. Determine the minimum number of stations needed. (Use your rounded cycle time from Part b. Round up your answer to a utiole number. Note that rounding up to one decimal point may reduce output to slightly less than 250 and this is fine.) d. Using the calculated cycle time, assign tasks to workstations on the basis of most following tasks. Use shortest processing time as a tiebreaker. Specify tasks in the exact order they were assigned. Answer is complete and correct. e. Compute the percent efficiency and percent idle time for the assignment in part d. Note: if the calculated cycle time and the actual bottleneck station time are different, use the actual bottleneck time in your calculations. (Round your answers to 2 decimal places) Answer is complete but not entirely correct

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts