Question: only need help with part b and c Macon Controls produces three different types of control units used to protect industrial equipment from overheating. Each

only need help with part b and c

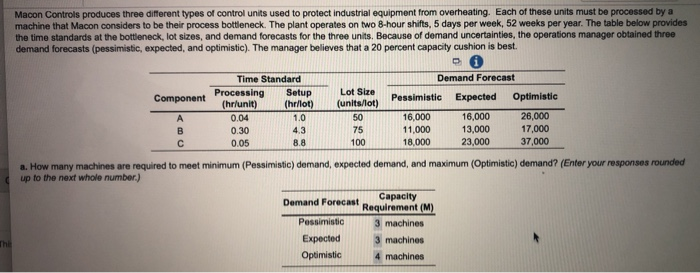

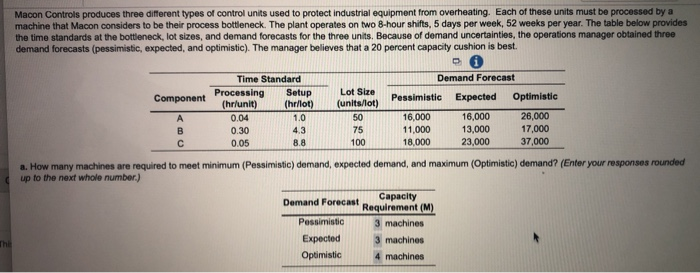

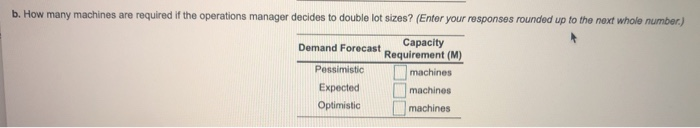

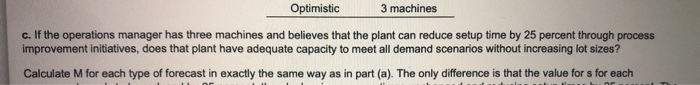

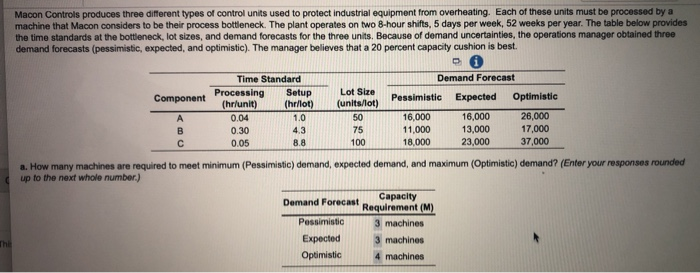

Macon Controls produces three different types of control units used to protect industrial equipment from overheating. Each of these units must be processed by a machine that Macon considers to be their process bottleneck. The plant operates on two 8-hour shifts, 5 days per week, 52 weeks per year. The table below provides the time standards at the bottleneck, lot sizes, and demand forecasts for the three units. Because of demand uncertainties, the operations manager obtained three demand forecasts (pessimistic, expected, and optimistic). The manager believes that a 20 percent capacity cushion is best. Demand Forecast Component Pessimistic Time Standard Processing Setup (hrlunit) (hrllot) 0.04 1.0 0.30 4.3 0.05 8.8 B Lot Size (units/lot) 50 75 100 16,000 11,000 18,000 Expected 16,000 13,000 23,000 Optimistic 26,000 17,000 37,000 a. How many machines are required to meet minimum (Pessimistic) demand, expected demand, and maximum (Optimistic) demand? (Enter your responses rounded up to the next whole number.) Demand Forecast Capacity Requirement (M) Pessimistic 3 machines Expected 3 machines Optimistic 4 machines The b. How many machines are required if the operations manager decides to double lot sizes? (Enter your responses rounded up to the next whole number.) Demand Forecast Capacity Requirement (M) Pessimistic machines Expected machines Optimistic machines Optimistic 3 machines c. If the operations manager has three machines and believes that the plant can reduce setup time by 25 percent through process improvement initiatives, does that plant have adequate capacity to meet all demand scenarios without increasing lot sizes? Calculate M for each type of forecast in exactly the same way as in part (a). The only difference is that the value for s for each Macon Controls produces three different types of control units used to protect industrial equipment from overheating. Each of these units must be processed by a machine that Macon considers to be their process bottleneck. The plant operates on two 8-hour shifts, 5 days per week, 52 weeks per year. The table below provides the time standards at the bottleneck, lot sizes, and demand forecasts for the three units. Because of demand uncertainties, the operations manager obtained three demand forecasts (pessimistic, expected, and optimistic). The manager believes that a 20 percent capacity cushion is best. Demand Forecast Component Pessimistic Time Standard Processing Setup (hrlunit) (hrllot) 0.04 1.0 0.30 4.3 0.05 8.8 B Lot Size (units/lot) 50 75 100 16,000 11,000 18,000 Expected 16,000 13,000 23,000 Optimistic 26,000 17,000 37,000 a. How many machines are required to meet minimum (Pessimistic) demand, expected demand, and maximum (Optimistic) demand? (Enter your responses rounded up to the next whole number.) Demand Forecast Capacity Requirement (M) Pessimistic 3 machines Expected 3 machines Optimistic 4 machines The b. How many machines are required if the operations manager decides to double lot sizes? (Enter your responses rounded up to the next whole number.) Demand Forecast Capacity Requirement (M) Pessimistic machines Expected machines Optimistic machines Optimistic 3 machines c. If the operations manager has three machines and believes that the plant can reduce setup time by 25 percent through process improvement initiatives, does that plant have adequate capacity to meet all demand scenarios without increasing lot sizes? Calculate M for each type of forecast in exactly the same way as in part (a). The only difference is that the value for s for each