Question: Only need part b, part a is 100% correct b. Compare the costs to a level plan that uses inventory to absorb fluctuations Inventory carrying

Only need part b, part a is 100% correct

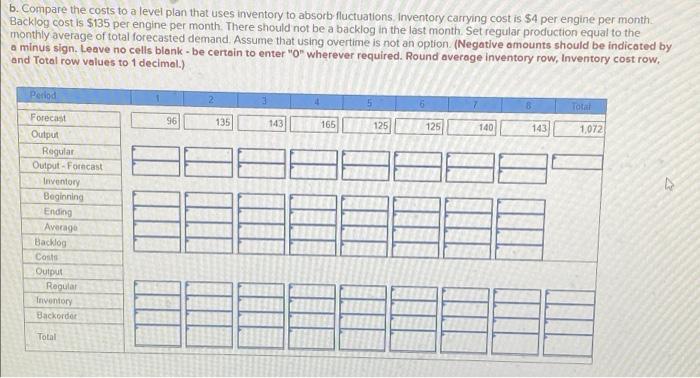

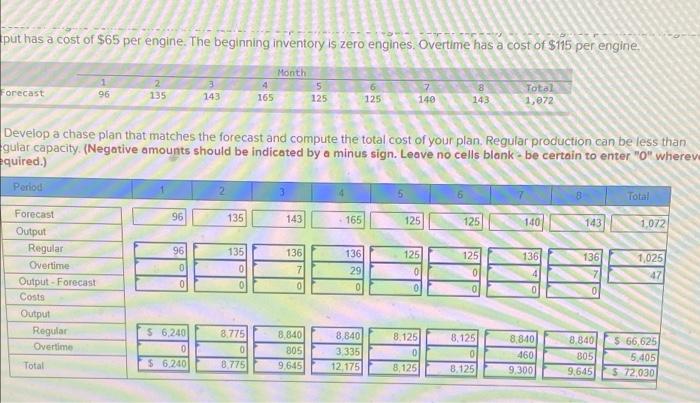

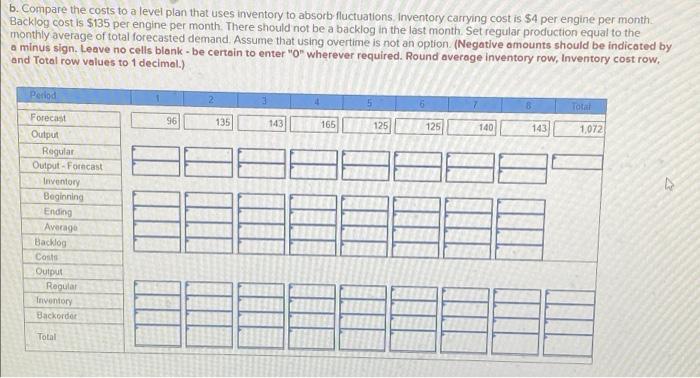

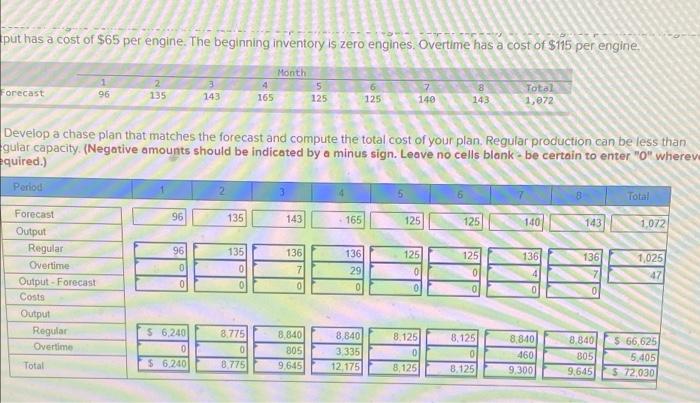

b. Compare the costs to a level plan that uses inventory to absorb fluctuations Inventory carrying cost is $4 per engine per month Backlog cost is $135 per engine per month. There should not be a backlog in the last month Set regular production equal to the monthly average of total forecasted demand. Assume that using overtime is not an option (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "o" wherever required. Round average inventory row, Inventory cost row. and Total row values to 1 decimal.) Perlod 5 Total 96 135 143 165 125 125 140 143 1,072 Forecast Output Regular Output-Forcast Inventory Beginning Ending Average Backlog Costs Output Regular Inventory Backorder Total put has a cost of $65 per engine. The beginning inventory is zero engines. Overtime has a cost of $115 per engine. Month 4 5 165 125 Forecast 2 135 96 743 125 140 8 143 Total 1,072 Develop a chase plan that matches the forecast and compute the total cost of your plan. Regular production can be less than gular capacity. (Negative amounts should be indicated by a minus sign. Leave no cells blank - be certain to enter "0" whereve quired.) Period 2 5 Total 96 135 143 165 125 125 140 143 1,072 96 0 136 7 136 135 0 0 136 136 29 0 125 0 Forecast Output Regular Overtime Output - Forecast Costs Output Regular Overtime Total 125 0 0 1,025 47 0 0 0 0 $ 6.240 0 $ 6,240 8.775 0 8.775 8.840 805 9,645 8.840 3,335 12 175 8.125 0 8.1251 8.125 0 8.125 8.840 460 9,300 8.840 $ 66,625 805 5.405 9,645 $72,030

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock