Question: OPERATION MANAGEMENT 3 . DON'T USE AIBI WILL DISLIKE A company manufactures high - demand personal electronic devices. The company operates a production line that

OPERATION MANAGEMENT

DON'T USE AIBI WILL DISLIKE

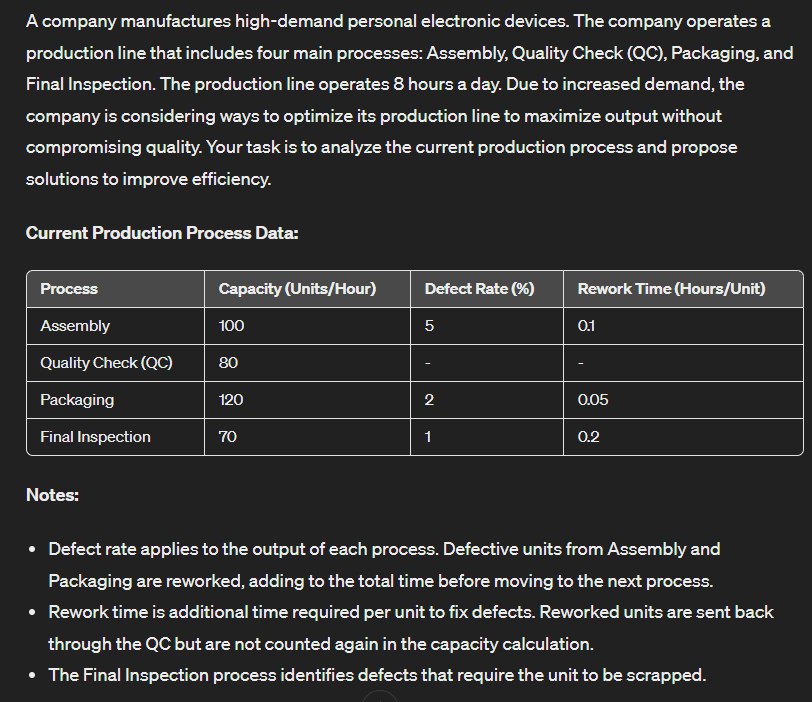

A company manufactures highdemand personal electronic devices. The company operates a production line that includes four main processes: Assembly, Quality Check QC Packaging, and Final Inspection. The production line operates hours a day. Due to increased demand, the company is considering ways to optimize its production line to maximize output without compromising quality. Your task is to analyze the current production process and propose solutions to improve efficiency.

Current Production Process Data:

tableProcessCapacity UnitsHourDefect Rate Rework Time HoursUnitAssemblyQuality Check QCPackagingFinal Inspection,

Notes:

Defect rate applies to the output of each process. Defective units from Assembly and Packaging are reworked, adding to the total time before moving to the next process.

Rework time is additional time required per unit to fix defects. Reworked units are sent back through the QC but are not counted again in the capacity calculation.

The Final Inspection process identifies defects that require the unit to be scrapped.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock