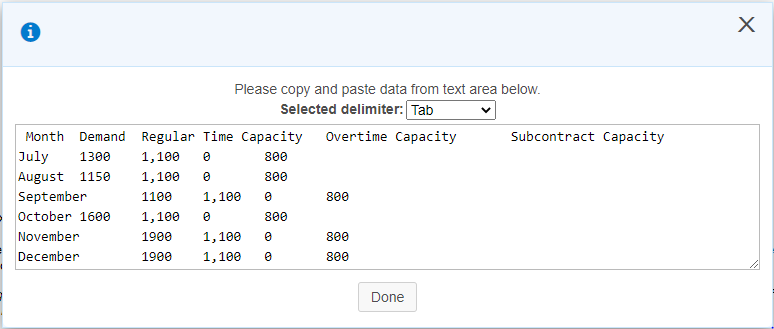

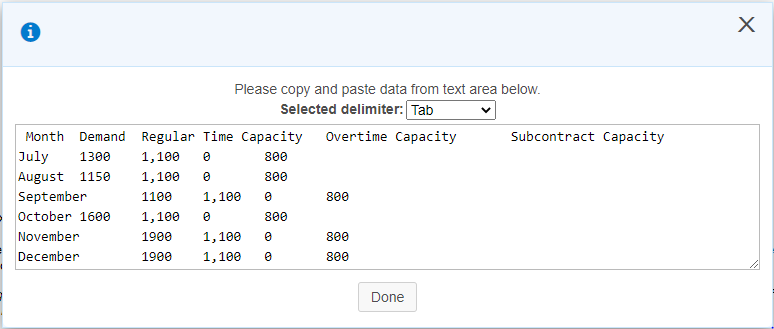

Question: Operations Management Please copy and paste data from text area below. Selected delimiter: Tab Month Demand Regular Time Capacity Overtime Capacity Subcontract Capacity July 1300

Operations Management

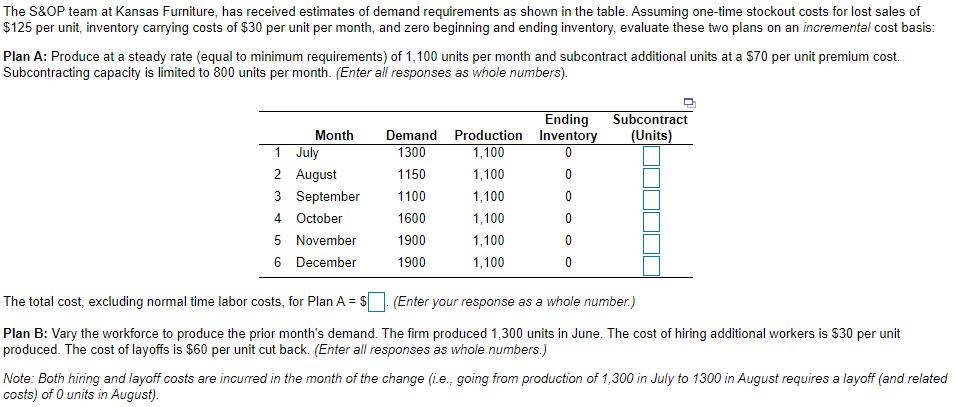

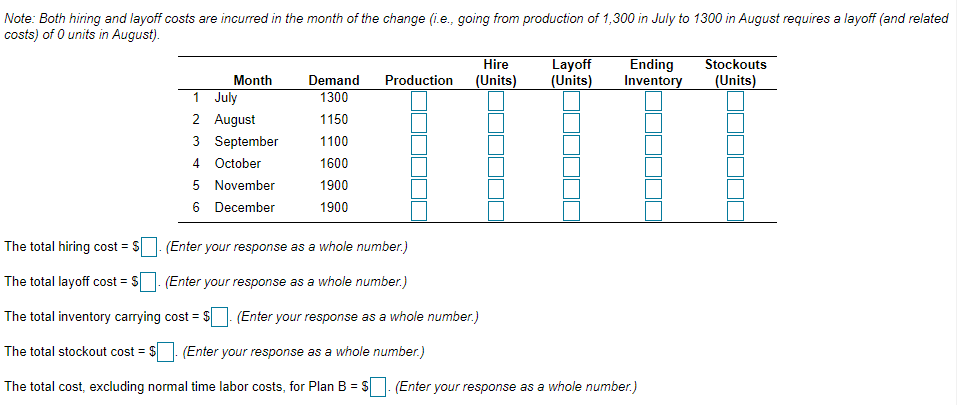

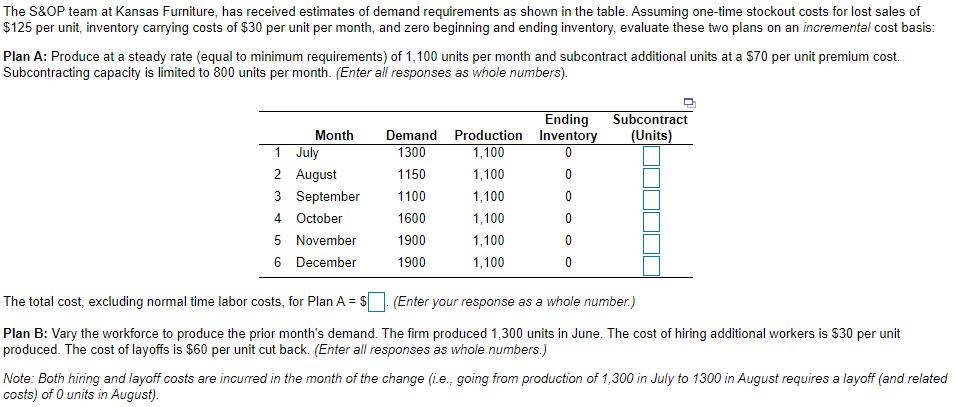

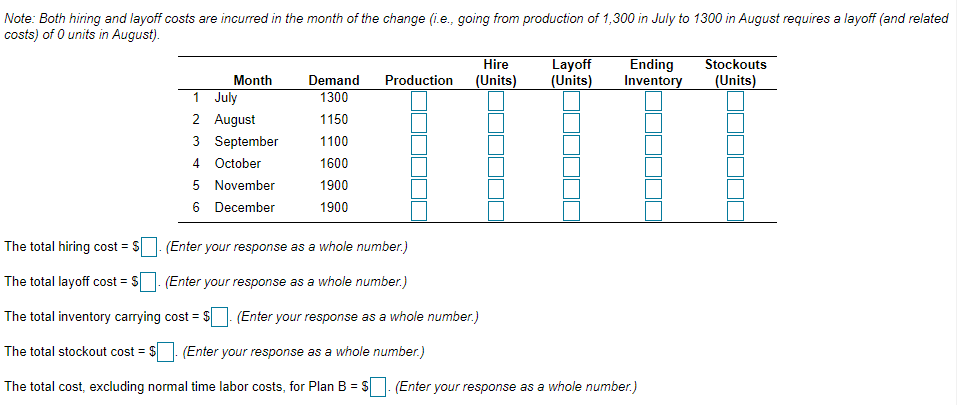

Please copy and paste data from text area below. Selected delimiter: Tab Month Demand Regular Time Capacity Overtime Capacity Subcontract Capacity July 1300 1,100 0 800 August 1150 1,100 800 September 1100 1,100 0 800 October 1600 1,100 800 November 1900 1,100 800 December 1900 1,100 800 0 0 Done The S&OP team at Kansas Furniture, has received estimates of demand requirements as shown in the table. Assuming one-time stockout costs for lost sales of $125 per unit, inventory carrying costs of $30 per unit per month, and zero beginning and ending inventory, evaluate these two plans on an incremental cost basis: Plan A: Produce at a steady rate (equal to minimum requirements) of 1,100 units per month and subcontract additional units at a $70 per unit premium cost. Subcontracting capacity is limited to 800 units per month. (Enter all responses as whole numbers). Month 1 July 2 August 3 September 4 October 5 November 6 December Ending Subcontract Demand Production Inventory (Units) 1300 1,100 1150 1,100 0 1100 1,100 0 1600 1,100 0 1900 1,100 0 1900 1,100 0 The total cost, excluding normal time labor costs, for Plan A = $[ (Enter your response as a whole number.) Plan B: Vary the workforce to produce the prior month's demand. The firm produced 1,300 units in June. The cost of hiring additional workers is $30 per unit produced. The cost of layoffs is $60 per unit cut back. (Enter all responses as whole numbers.) Note: Both hiring and layoff costs are incurred in the month of the change (i.e., going from production of 1,300 in July to 1300 in August requires a layoff (and related costs) of O units in August). 1 July Note: Both hiring and layoff costs are incurred in the month of the change (i.e., going from production of 1,300 in July to 1300 in August requires a layoff (and related costs) of O units in August). Hire Layoff Ending Stockouts Month Demand Production (Units) (Units) Inventory (Units) 1300 2 August 1150 3 September 1100 4 October 1600 5 November 1900 6 December 1900 The total hiring cost = 5 (Enter your response as a whole number.) The total layoff cost = $(Enter your response as a whole number.) The total inventory carrying cost = $ (Enter your response as a whole number.) The total stockout cost = = $ (Enter your response as a whole number.) The total cost, excluding normal time labor costs, for Plan B = $(Enter your response as a whole number.) Please copy and paste data from text area below. Selected delimiter: Tab Month Demand Regular Time Capacity Overtime Capacity Subcontract Capacity July 1300 1,100 0 800 August 1150 1,100 800 September 1100 1,100 0 800 October 1600 1,100 800 November 1900 1,100 800 December 1900 1,100 800 0 0 Done The S&OP team at Kansas Furniture, has received estimates of demand requirements as shown in the table. Assuming one-time stockout costs for lost sales of $125 per unit, inventory carrying costs of $30 per unit per month, and zero beginning and ending inventory, evaluate these two plans on an incremental cost basis: Plan A: Produce at a steady rate (equal to minimum requirements) of 1,100 units per month and subcontract additional units at a $70 per unit premium cost. Subcontracting capacity is limited to 800 units per month. (Enter all responses as whole numbers). Month 1 July 2 August 3 September 4 October 5 November 6 December Ending Subcontract Demand Production Inventory (Units) 1300 1,100 1150 1,100 0 1100 1,100 0 1600 1,100 0 1900 1,100 0 1900 1,100 0 The total cost, excluding normal time labor costs, for Plan A = $[ (Enter your response as a whole number.) Plan B: Vary the workforce to produce the prior month's demand. The firm produced 1,300 units in June. The cost of hiring additional workers is $30 per unit produced. The cost of layoffs is $60 per unit cut back. (Enter all responses as whole numbers.) Note: Both hiring and layoff costs are incurred in the month of the change (i.e., going from production of 1,300 in July to 1300 in August requires a layoff (and related costs) of O units in August). 1 July Note: Both hiring and layoff costs are incurred in the month of the change (i.e., going from production of 1,300 in July to 1300 in August requires a layoff (and related costs) of O units in August). Hire Layoff Ending Stockouts Month Demand Production (Units) (Units) Inventory (Units) 1300 2 August 1150 3 September 1100 4 October 1600 5 November 1900 6 December 1900 The total hiring cost = 5 (Enter your response as a whole number.) The total layoff cost = $(Enter your response as a whole number.) The total inventory carrying cost = $ (Enter your response as a whole number.) The total stockout cost = = $ (Enter your response as a whole number.) The total cost, excluding normal time labor costs, for Plan B = $(Enter your response as a whole number.)