Question: operations management please help to answer the questions starting image no 6 start from picture no 6 XYZ Co is a gromierot company in the

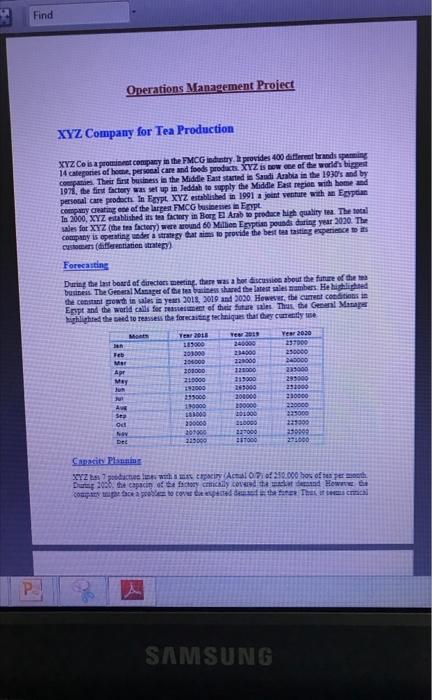

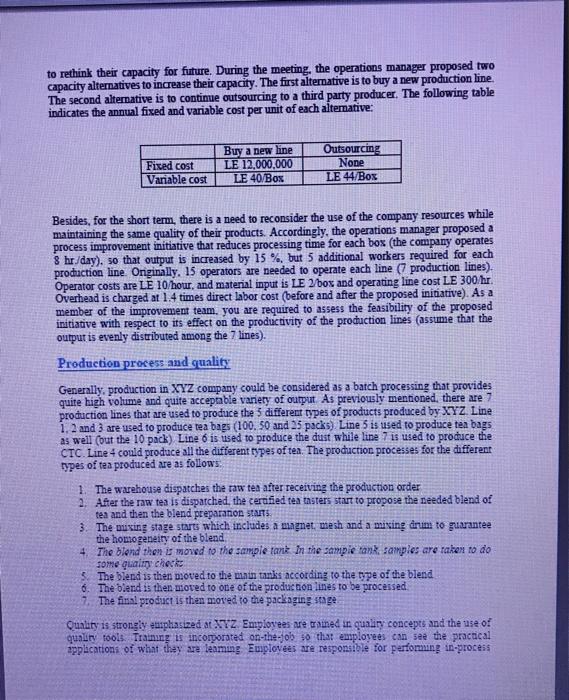

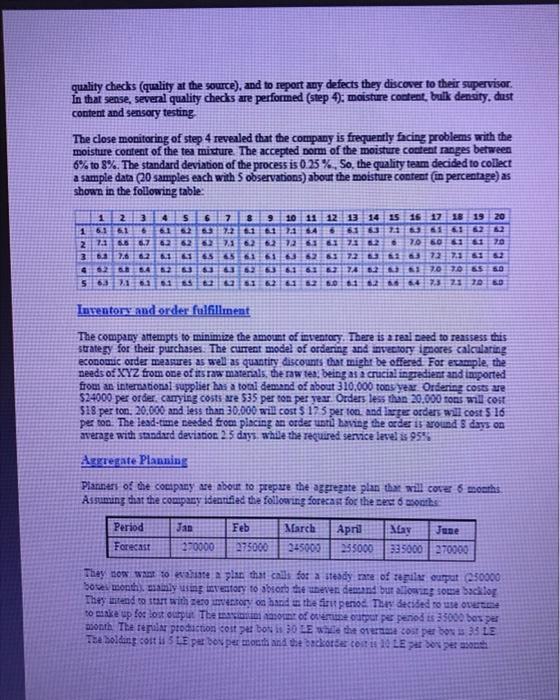

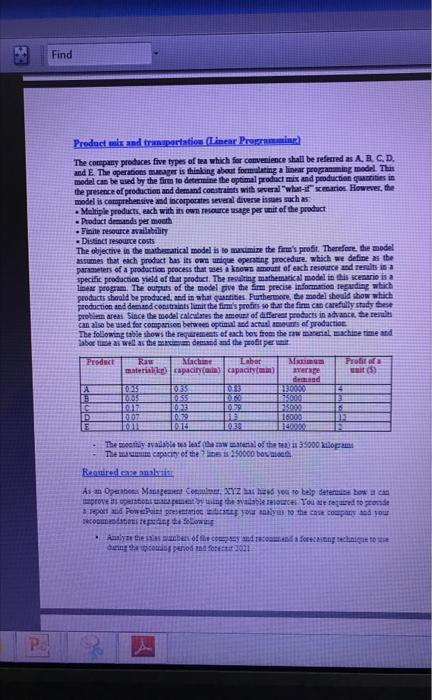

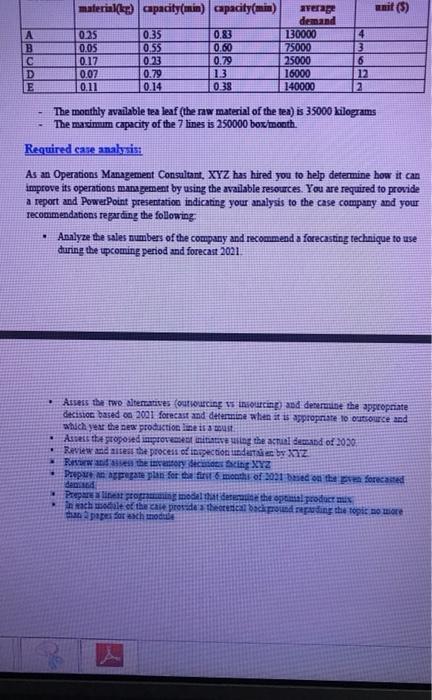

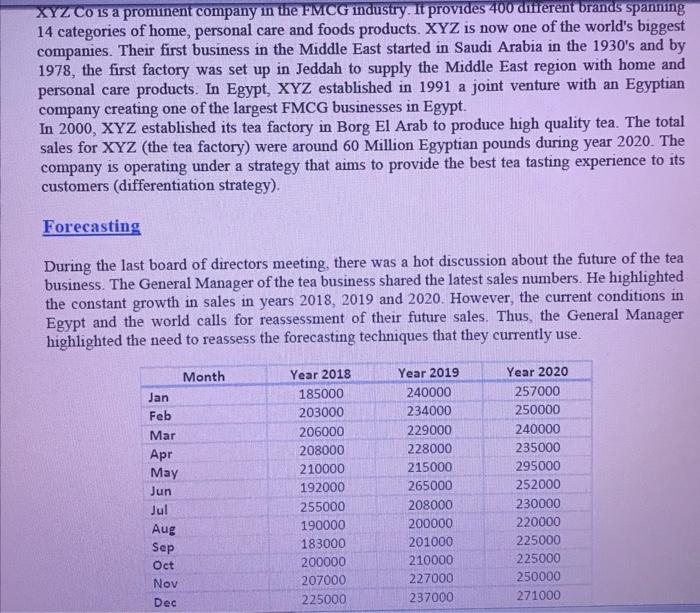

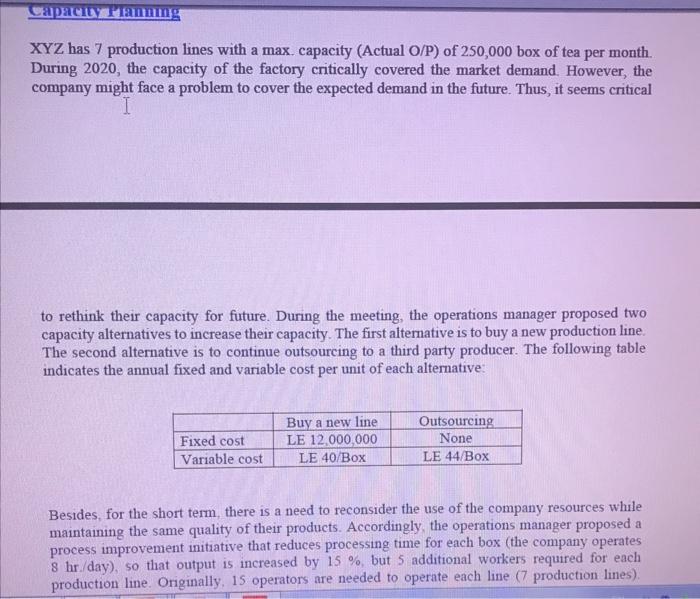

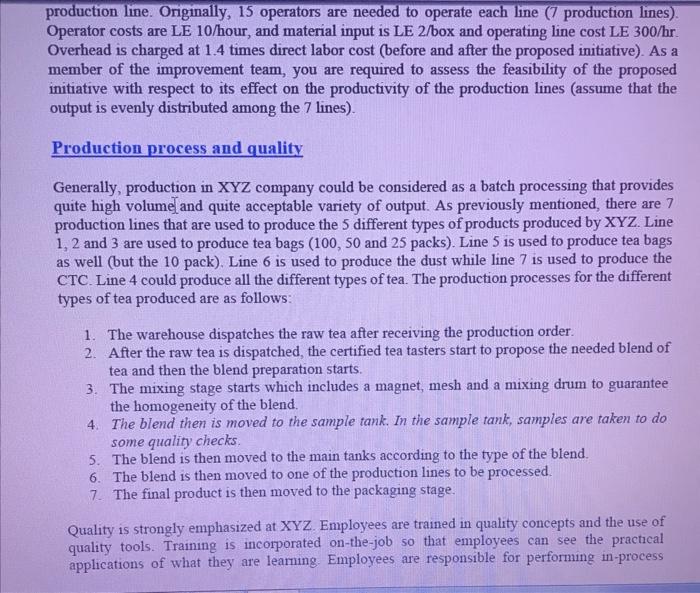

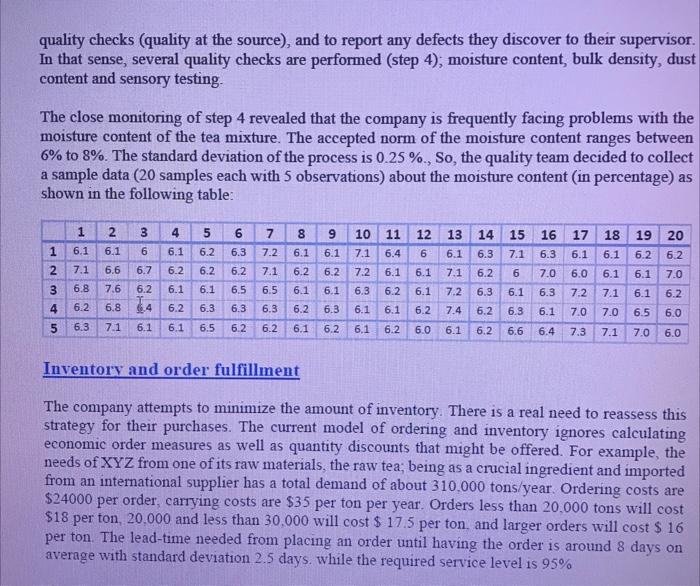

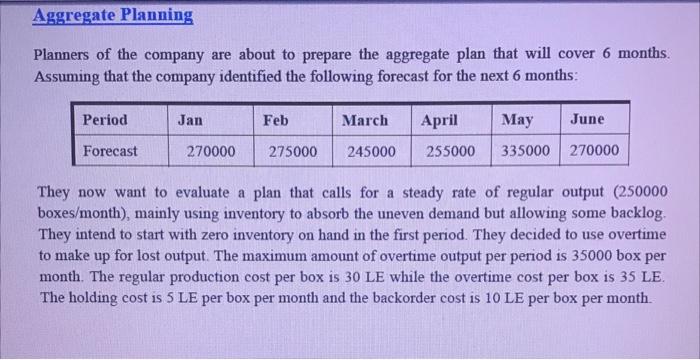

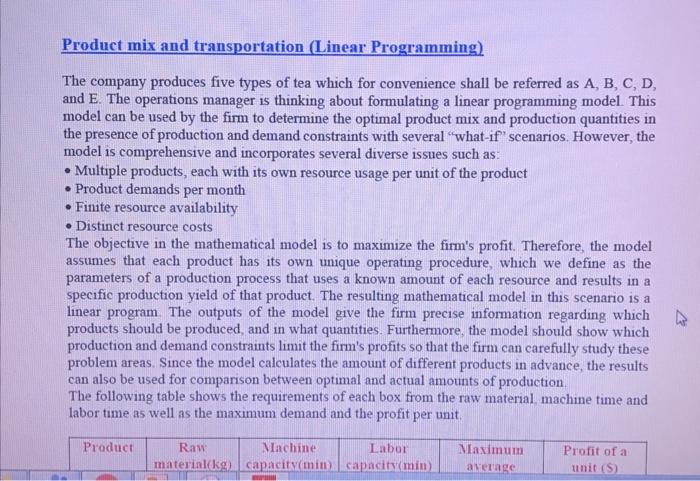

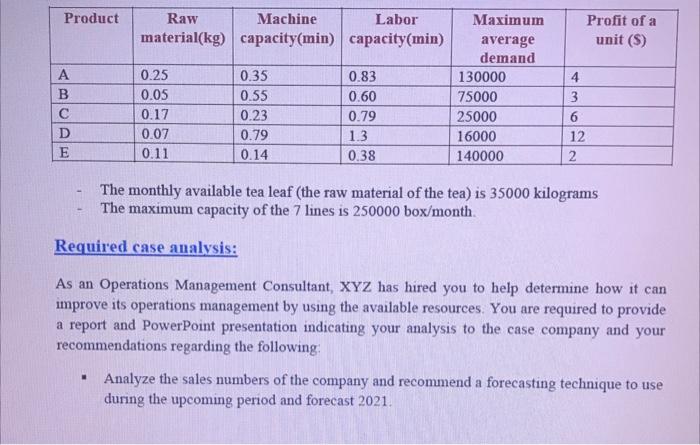

XYZ Co is a gromierot company in the FMCG induaty. I grovites 400 differeat trands mperming 14 cateponies of hoene, pesenal care and foods prodxets. XYZ is pow coe of the worlds bigged coeparies. Ther fint bucines in the Midille East startad in Saudi Arabla in the 1930's and by 1978, the find factory was set up in Jediah to supply fhe Middle East regioe arith home and persocal care products in Esypt. XYZZ establisbed in 1991 a joint venture with an Espotan. conpary creating ene of the largets FMCG tusiaesses tn Eopt. In 2000, XIZ eivbliched its ten fictary in Bors El Arab wo produce high quaing tea. The toca: was fot XYZ (the tea factory) were around 60 Milben Esprian pousds during year 2020 . The company is operating ueder a stategy tat aims to peovide the beit tas tastieg ecpeniesce to its cassomes (ditterentiation itrate;y). Forecasting During the Lest bosrd of directors meesing, there was a ber discusiee about the funure of the was the censtant gowth is ulas in yeat 2018, 2019 and 2080. Howerer, the current cosistiater in Capacio. Phanging to rethink their capacity for future. During the meeting, the operations manager proposed two capacity alternatives to increase their capacity. The first alternative is to buy a new production line. The second alternative is to continue outsourcing to a third party producer. The following table indicates the annual fixed and variable cost per unit of each altemative: Besides, for the short term, there is a need to reconsider the use of the company resources while maintaining the same quality of their products. Accordingly, the operations manager proposed a process improvement initiative that reduces processing time for each bos (the company operates 8hr/ dayy), so that ourpur is increased by 15%, but 5 additional workers required for each prodaction line. Originally. 15 operators are needed to operate each line (7 production lines). Operator costs are LE 10 hour, and material input is LE 2 bos and operating line cost LE 300hr. Overhead is charged at 1.4 times direct labor cost (before and after the proposed initiative). As a member of the improvement team. you are required to assess the feasibility of the proposed initiative with respect to its effect on the productivity of the production lines (assume that the output is evenly distributed among the 7 lines). Production process and quality Genenilly, production in XYZ company could be considered as a batch processing that provides quite ligh, volume and quite acceppable variery of output As previously mentioned, there are 7 production lines that are used to produce the 3 different types of products produced by XYZ. L ine 1,2 and 3 are used to produce tea bags (100, 50 and 25 packs) Line 5 is used to produce tea bags as well (out the 10 pach) Line 6 is used to produce the dust while line 7 is used to procice the CTC. Line 4 could produce all the different types of tea. The production processes for the different types of tea produced are as follows: 1. The warehouse dispatches the raw tea after receiving the production order 2. After the nw tea is dispatched, the cerafied tes tasters stut to propose the needed blend of tea and then the blend ptegaranon stars. 3. The nuxing stage stars which includes a magnet, we sh and a mixing tirum to guarantee the homogeneiry of the blend 4. The blend then is moved to the sample tank in the sampie tank, samples are taken to do some quairy chock 5. The blend is then pooved to the mnin tatis according to the type of the blend 6. The blend is then Iroved to octe of the producton lines to be grocessed. 7. The find product is than moved to the packoging sage Qualty is strongiy emphasized at XVZ. Enpioveas are tained in qualir concepts and the use of quality tools. Traing is incorporated on-the-fois to that employees can see the practical ipplications of what thay ae laaming Euploves are responsible for performing in-process quality checks (quality at the source), and to report any defects they discover to their supervisor. in that sense, several quality checks are performed (step 4); moisture content, bulk dencity, dust content and sensory testing. The close monitoring of step 4 revealed that the company is frequently facing problems with the moisture content of the tea mixure. The accepted nomm of the moisture content ranges betareen 6% to 8%. The standard deviation of the process is 0.25%, So, the quality team decided to collect a sample data (20 samples each with 5 observations) about the moisture conteat (in percentage) as shown in the following table: Inxentory and order fulfiliment The company attempts to minimize the amount of inventory. There is a real seed to reassess this strategy for their purchases. The current model of ordering and mvectory igeores calcularing economic order measures as well as quantiry discounts that mighr be offered For example, the needs of XYZ from one of its raw matenals, the raw tea, being as 2 crucial ingredient and ingorted from an internstional supplier has a total demand of about 310,000 tons yex. Ordering costs are $24000 per order, camying costs are $35 per ton per year. Orders less than 20.000 roms anll cost 518 per ton. 20,000 and less than 30.000 will cost 5175 per toa and lurger orders alll cost 516 per ton. The leadetime neaded from plecing an order until havieg the order is around 3 drys on average with standird derianoe 25 diys. while the recuired service level is 95% Aggregate Planning Pianneri of the cocapay are abou to prepure the agerezate plan than will cover 5 mocths: Asmuming that the company idtanifiad the folloning Sorecan for the zere 6 asoarke: wionth The repolly ptoduction soit pet botidi 70 in shile the overaed cost pet bot is 36 is Prodact mis and tranpartation (finear Programatins) The company produces five types of tea which for comsenience shall be refared as A, B, C. D. and E. The operabous macage is dinking about formuliting a linear programming modrl. Thin model cos be aved by the firm to detrmine the optimal protuct mix and poodiction castribies in the presence of probiction and demand cocitraints with uveral " what-if" scrourios However, the model is comprebensive and incorpocates sevenl divere ismes such as: - Maltiple pcoducts, each with its own revance asage per unit of the product - Prodact demanda per moes - Fraine resource srathbaliby - Distinct resource costs The objective in the matheratical model is so mondinise the fimis profit. Therefore the aode! assumes that each protuct bas its oan unique epenting procedure. which we define at the purametess of a protuction ptocess that wes a ksoms amount of sach resource asd renals is a ipecific prodaction pield of that product. The resalting mathematical model in tiss scenario is a prodacts shoald be produced, and in what quatises. Furtermore, te motel sbeald thow which prodictien and deanod conetraints linit the fintrs srofin so that the fim con carefully stady tese. cin also be uned for compansoa between optimal abd actat atouns of proctaction - The eocthy avalahit wes lef far aw zotend of the taz ir 35500 kiLo Fams Reagired mene analyini Trobentsdineti teperief ti thtowing - The monthly available tea leaf (the raw material of the tea) is 35000 kilograms - The maximum capacity of the 7 lines is 250000 box'mooth. Required case analyst As an Operations Management Consaltant, XYZ has hired you to help detenmine how it can improve its operations management by using the available resources. You are required to provide a report and Powerpoint presentation indicating your analysis to the case company and your recommendations re parding the following: - Analyze the sales numbers of the company and recommend a forecasting technique to use duing the upcouring period and forecast 2021 - Ausess the two altenanives (oatwarcing wr mipurcing) asd denermine the apgropniate decistee based oo 2021 fotecait and dtternine when it 4 approprate 10 outsource and which yetr the neas groduction line is a zuit - Asseis the groposed inproteaset initimwe uing the acpaal demand of 2020 . - Revieir amd artest the proctis of iorpecton underaiec by Roz. Aenied XYZ Co is a prominent company in the FMCG indusiry. It provides 400 different brands spanning 14 categories of home, personal care and foods products. XYZ is now one of the world's biggest companies. Their first business in the Middle East started in Saudi Arabia in the 1930's and by 1978 , the first factory was set up in Jeddah to supply the Middle East region with home and personal care products. In Egypt, XYZ established in 1991 a joint venture with an Egyptian company creating one of the largest FMCG businesses in Egypt. In 2000,XYZ established its tea factory in Borg El Arab to produce high quality tea. The total sales for XYZ (the tea factory) were around 60 Million Egyptian pounds during year 2020. The company is operating under a strategy that aims to provide the best tea tasting experience to its customers (differentiation strategy). Forecasting During the last board of directors meeting, there was a hot discussion about the future of the tea business. The General Manager of the tea business shared the latest sales numbers. He highlighted the constant growth in sales in years 2018, 2019 and 2020. However, the current conditions in Egypt and the world calls for reassessment of their future sales. Thus, the General Manager highlighted the need to reassess the forecasting techniques that they currently use. XYZ has 7 production lines with a max. capacity (Actual O/P) of 250,000 box of tea per month. During 2020, the capacity of the factory critically covered the market demand. However, the company might face a problem to cover the expected demand in the future. Thus, it seems critical to rethink their capacity for future. During the meeting, the operations manager proposed two capacity alternatives to increase their capacity. The first alternative is to buy a new production line. The second alternative is to continue outsourcing to a third party producer. The following table indicates the annual fixed and variable cost per unit of each alternative: Besides, for the short term, there is a need to reconsider the use of the company resources while maintaining the same quality of their products. Accordingly, the operations manager proposed a process improvement initiative that reduces processing time for each box (the company operates 8hr. day), so that output is increased by 15%, but 5 additional workers required for each production line. Originally, 15 operators are needed to operate each line ( 7 production lines). production line. Originally, 15 operators are needed to operate each line (7 production lines). Operator costs are LE 10/hour, and material input is LE 2/ box and operating line cost LE 300/hr. Overhead is charged at 1.4 times direct labor cost (before and after the proposed initiative). As a member of the improvement team, you are required to assess the feasibility of the proposed initiative with respect to its effect on the productivity of the production lines (assume that the output is evenly distributed among the 7 lines). Production process and quality Generally, production in XYZ company could be considered as a batch processing that provides quite high volume and quite acceptable variety of output. As previously mentioned, there are 7 production lines that are used to produce the 5 different types of products produced by XYZ. Line 1,2 and 3 are used to produce tea bags (100,50 and 25 packs). Line 5 is used to produce tea bags as well (but the 10 pack). Line 6 is used to produce the dust while line 7 is used to produce the CTC. Line 4 could produce all the different types of tea. The production processes for the different types of tea produced are as follows: 1. The warehouse dispatches the raw tea after receiving the production order. 2. After the raw tea is dispatched, the certified tea tasters start to propose the needed blend of tea and then the blend preparation starts. 3. The mixing stage starts which includes a magnet, mesh and a mixing drum to guarantee the homogeneity of the blend. 4. The blend then is moved to the sample tank. In the sample tank, samples are taken to do some quality checks. 5. The blend is then moved to the main tanks according to the type of the blend. 6. The blend is then moved to one of the production lines to be processed. 7. The final product is then moved to the packaging stage. Quality is strongly emphasized at XYZ. Employees are trained in quality concepts and the use of quality tools. Training is incorporated on-the-job so that employees can see the practical applications of what they are learning. Employees are responsible for performing in-process quality checks (quality at the source), and to report any defects they discover to their supervisor. In that sense, several quality checks are performed (step 4); moisture content, bulk density, dust content and sensory testing. The close monitoring of step 4 revealed that the company is frequently facing problems with the moisture content of the tea mixture. The accepted norm of the moisture content ranges between 6% to 8%. The standard deviation of the process is 0.25%., So, the quality team decided to collect a sample data ( 20 samples each with 5 observations) about the moisture content (in percentage) as shown in the following table: Inventory and order fulfilliment The company attempts to minimize the amount of inventory. There is a real need to reassess this strategy for their purchases. The current model of ordering and inventory ignores calculating economic order measures as well as quantity discounts that might be offered. For example, the needs of XYZ from one of its raw materials, the raw tea; being as a crucial ingredient and imported from an international supplier has a total demand of about 310,000 tons/year. Ordering costs are $24000 per order, carrying costs are $35 per ton per year. Orders less than 20,000 tons will cost $18 per ton, 20,000 and less than 30,000 will cost $17.5 per ton. and larger orders will cost $16 per ton. The lead-time needed from placing an order until having the order is around 8 days on average with standard deviation 2.5 days. while the required service level is 95% Planners of the company are about to prepare the aggregate plan that will cover 6 months. Assuming that the company identified the following forecast for the next 6 months: They now want to evaluate a plan that calls for a steady rate of regular output (250000 boxes/month), mainly using inventory to absorb the uneven demand but allowing some backlog. They intend to start with zero inventory on hand in the first period. They decided to use overtime to make up for lost output. The maximum amount of overtime output per period is 35000 box per month. The regular production cost per box is 30LE while the overtime cost per box is 35LE. The holding cost is 5 LE per box per month and the backorder cost is 10LE per box per month. The company produces five types of tea which for convenience shall be referred as A, B, C, D, and E. The operations manager is thinking about formulating a linear programming model. This model can be used by the firm to determine the optimal product mix and production quantities in the presence of production and demand constraints with several "what-if' scenarios. However, the model is comprehensive and incorporates several diverse issues such as: - Multiple products, each with its own resource usage per unit of the product - Product demands per month - Finite resource availability - Distinct resource costs The objective in the mathematical model is to maximize the firm's profit. Therefore, the model assumes that each product has its own unique operating procedure, which we define as the parameters of a production process that uses a known amount of each resource and results in a specific production yield of that product. The resulting mathematical model in this scenario is a linear program. The outputs of the model give the firm precise information regarding which products should be produced, and in what quantities. Furthermore, the model should show which production and demand constraints limit the firm's profits so that the firm can carefully study these problem areas. Since the model calculates the amount of different products in advance, the results can also be used for comparison between optimal and actual amounts of production. The following table shows the requirements of each box from the raw material, machine time and labor time as well as the maximum demand and the profit per unit. - The monthly available tea leaf (the raw material of the tea) is 35000 kilograms - The maximum capacity of the 7 lines is 250000 box/month. Required case analysis: As an Operations Management Consultant, XYZ has hired you to help determine how it can improve its operations management by using the available resources. You are required to provide a report and PowerPoint presentation indicating your analysis to the case company and your recommendations regarding the following: - Analyze the sales numbers of the company and recommend a forecasting technique to use during the upcoming period and forecast 2021. - Assess the two alternatives (outsourcing vs insourcing) and determine the appropriate decision based on 2021 forecast and determine when it is appropriate to outsource and which year the new production line is a must. - Assess the proposed improvement initiative using the actual demand of 2020. - Review and assess the process of inspection undertaken by XYZ. - Review and assess the inventory decisions facing XYZ - Prepare an aggregate plan for the first 6 months of 2021 based on the given forecasted demand. - Prepare a linear programming model that determine the optimal product mix. - In each module of the case provide a theoretical background regarding the topic no more than 2 pages for each module

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts