Question: Output from a process contains 0.02 defective unit. Defective units that go undetected into final assemblies cost $25 each to replace. An inspection process, which

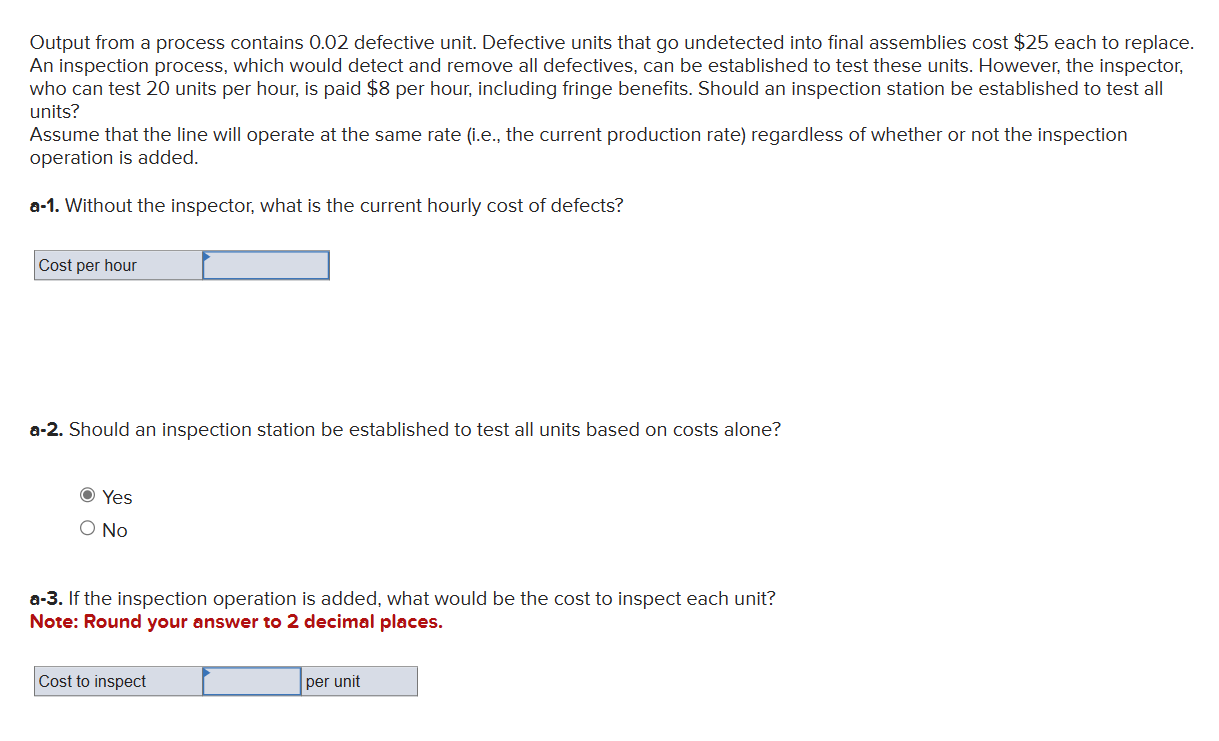

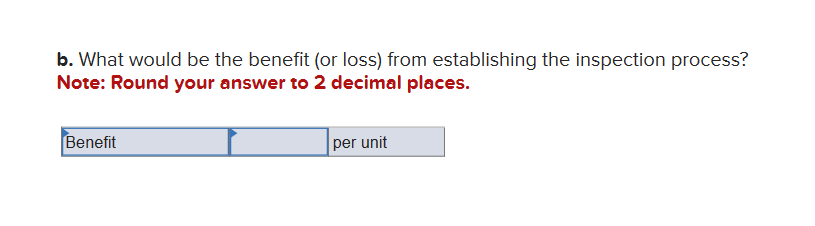

Output from a process contains 0.02 defective unit. Defective units that go undetected into final assemblies cost $25 each to replace. An inspection process, which would detect and remove all defectives, can be established to test these units. However, the inspector, who can test 20 units per hour, is paid $8 per hour, including fringe benefits. Should an inspection station be established to test all units? Assume that the line will operate at the same rate (i.e., the current production rate) regardless of whether or not the inspection operation is added. a-1. Without the inspector, what is the current hourly cost of defects? a-2. Should an inspection station be established to test all units based on costs alone? YesNo a-3. If the inspection operation is added, what would be the cost to inspect each unit? Note: Round your answer to 2 decimal places. b. What would be the benefit (or loss) from establishing the inspection process? Note: Round your answer to 2 decimal places

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts