Question: P 1 Create a design specification from a given design brief Vocational scenario Design Brief & Scenario: You work as a newly appointed design engineer

P Create a design specification from a given design brief

Vocational scenario

Design Brief & Scenario:

You work as a newly appointed design engineer for CheckMate a small manufacturing company

specialising in the manufacture of conveyor and inspection systems for the food industry. A new

company would like to add an inspection jig to one of their conveyor systems able to monitor the

production rate and daily volume of food products being made.

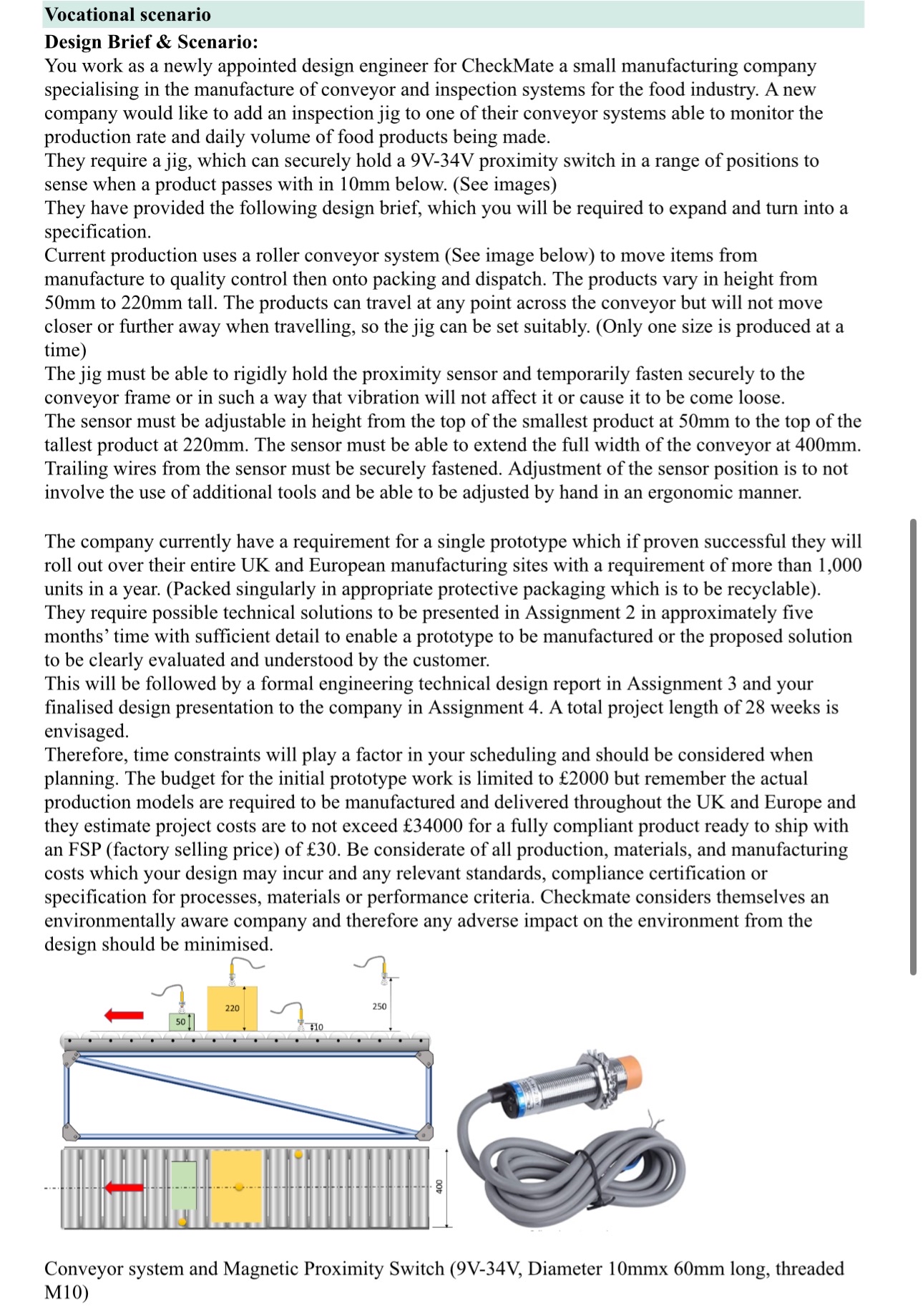

They require a jig, which can securely hold a proximity switch in a range of positions to

sense when a product passes with in mm below. See images

They have provided the following design brief, which you will be required to expand and turn into a

specification.

Current production uses a roller conveyor system See image below to move items from

manufacture to quality control then onto packing and dispatch. The products vary in height from

mm to mm tall. The products can travel at any point across the conveyor but will not move

closer or further away when travelling, so the jig can be set suitably. Only one size is produced at a

time

The jig must be able to rigidly hold the proximity sensor and temporarily fasten securely to the

conveyor frame or in such a way that vibration will not affect it or cause it to be come loose.

The sensor must be adjustable in height from the top of the smallest product at mm to the top of the

tallest product at mm The sensor must be able to extend the full width of the conveyor at mm

Trailing wires from the sensor must be securely fastened. Adjustment of the sensor position is to not

involve the use of additional tools and be able to be adjusted by hand in an ergonomic manner.

The company currently have a requirement for a single prototype which if proven successful they will

roll out over their entire UK and European manufacturing sites with a requirement of more than

units in a year. Packed singularly in appropriate protective packaging which is to be recyclable

They require possible technical solutions to be presented in Assignment in approximately five

months' time with sufficient detail to enable a prototype to be manufactured or the proposed solution

to be clearly evaluated and understood by the customer.

This will be followed by a formal engineering technical design report in Assignment and your

finalised design presentation to the company in Assignment A total project length of weeks is

envisaged.

Therefore, time constraints will play a factor in your scheduling and should be considered when

planning. The budget for the initial prototype work is limited to but remember the actual

production models are required to be manufactured and delivered throughout the UK and Europe and

they estimate project costs are to not exceed for a fully compliant product ready to ship with

an FSP factory selling price of Be considerate of all production, materials, and manufacturing

costs which your design may incur and any relevant standards, compliance certification or

specification for processes, materials or performance criteria. Checkmate considers themselves an

environmentally aware company and therefore any adverse impact on the environment from the

design should be minimised.

Conveyor system and Magnetic Proximity Switch VV Diameter mmx mm long, threaded

M

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock