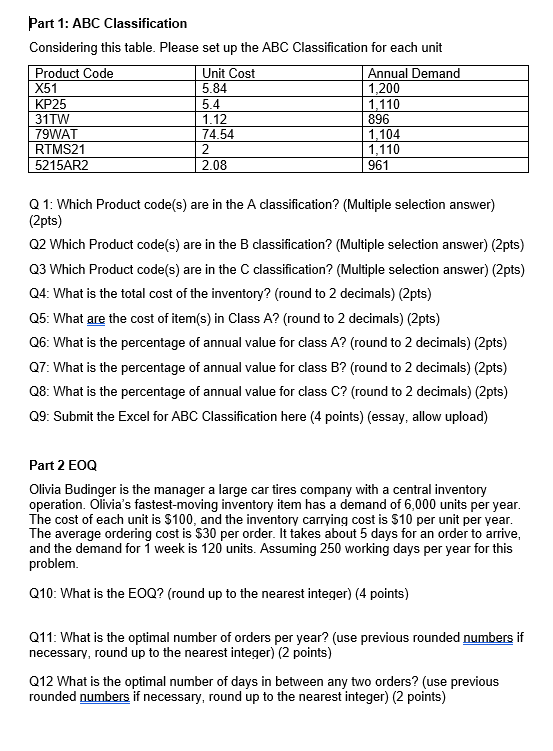

Question: Part 1: ABC Classification Considering this table. Please set up the ABC Classification for each unit Product Code Unit Cost Annual Demand X51 5.84 1,200

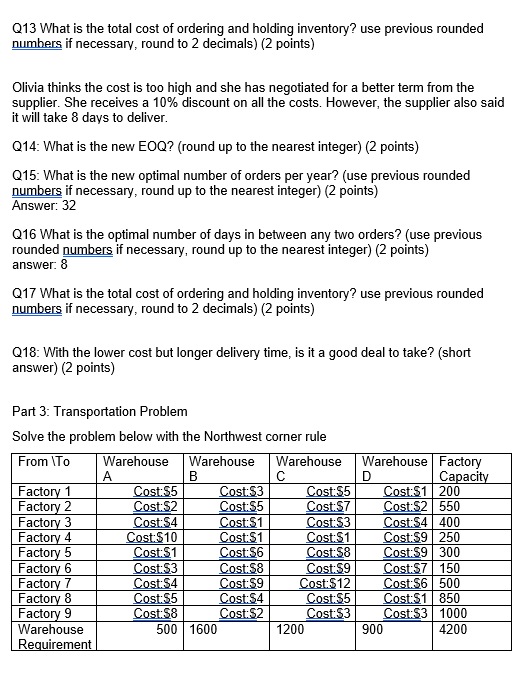

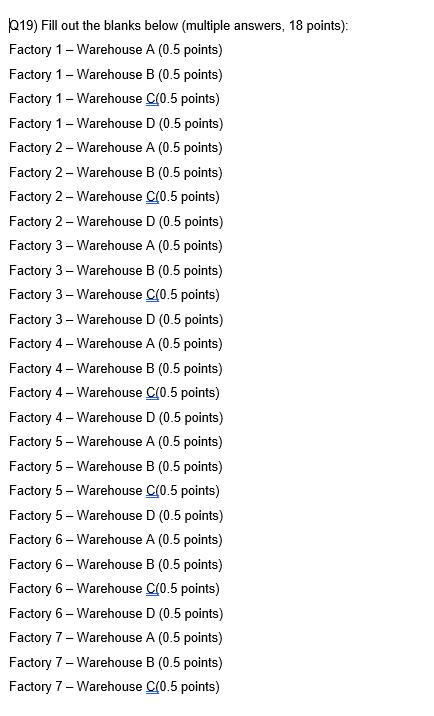

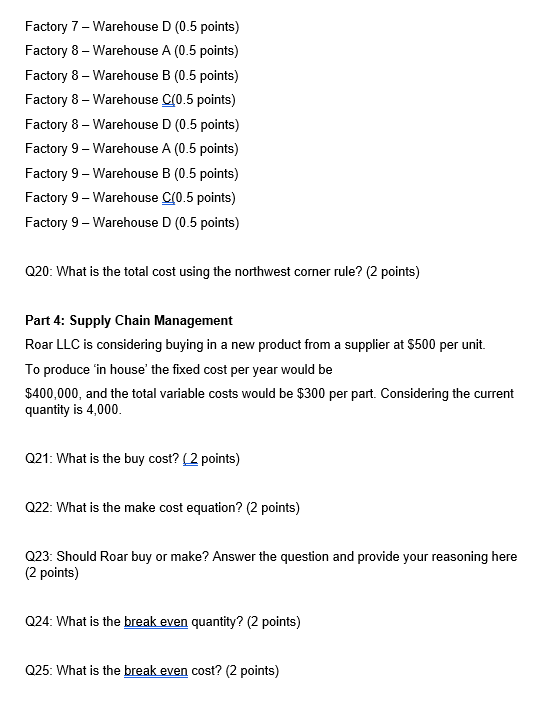

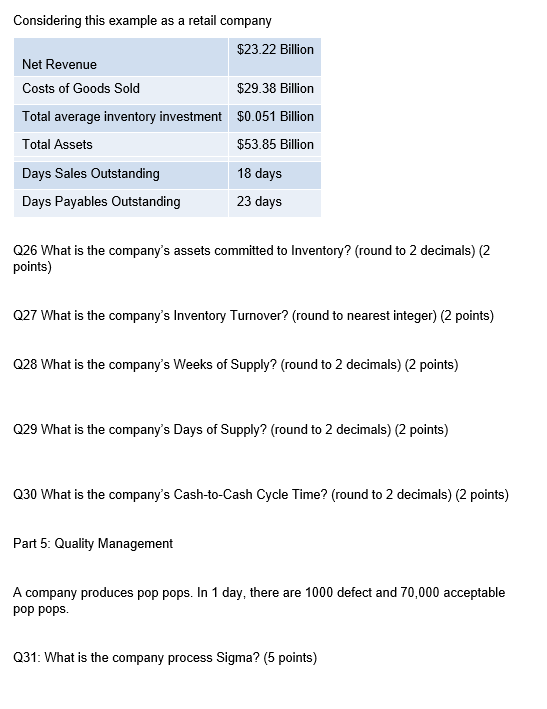

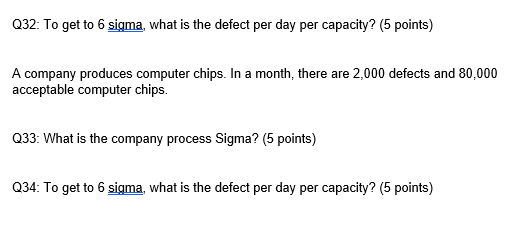

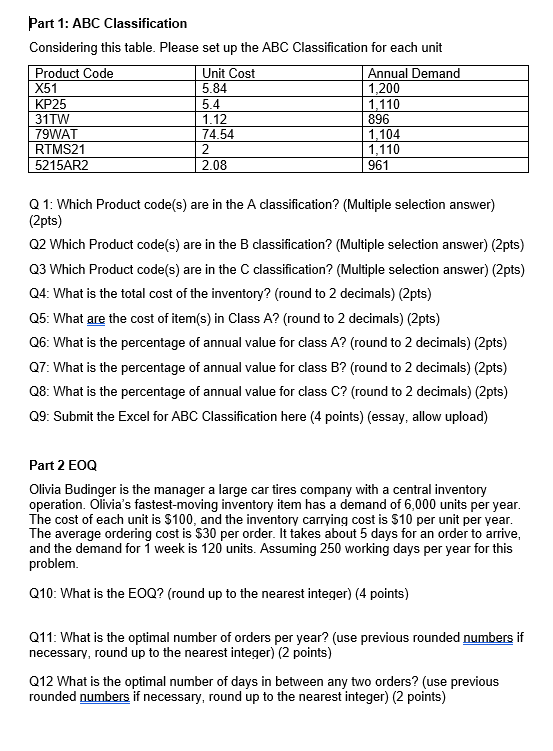

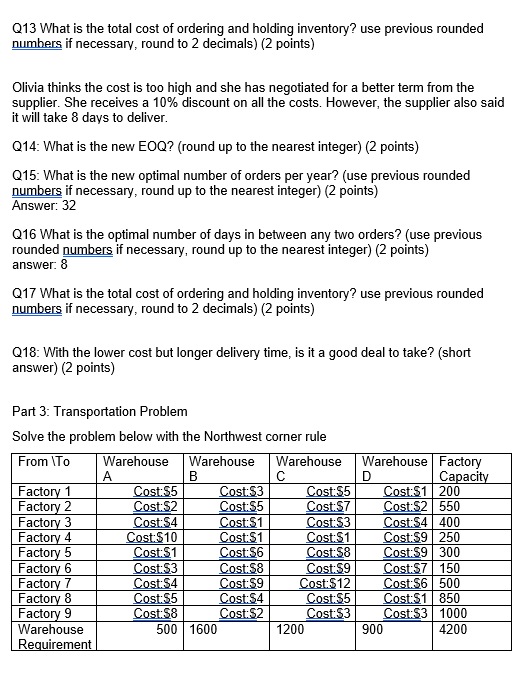

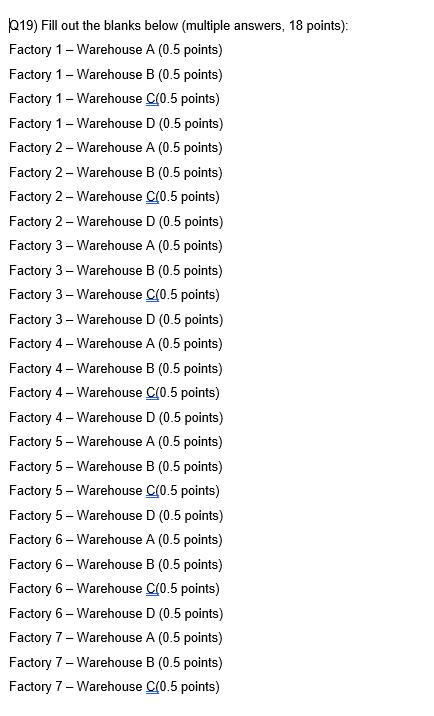

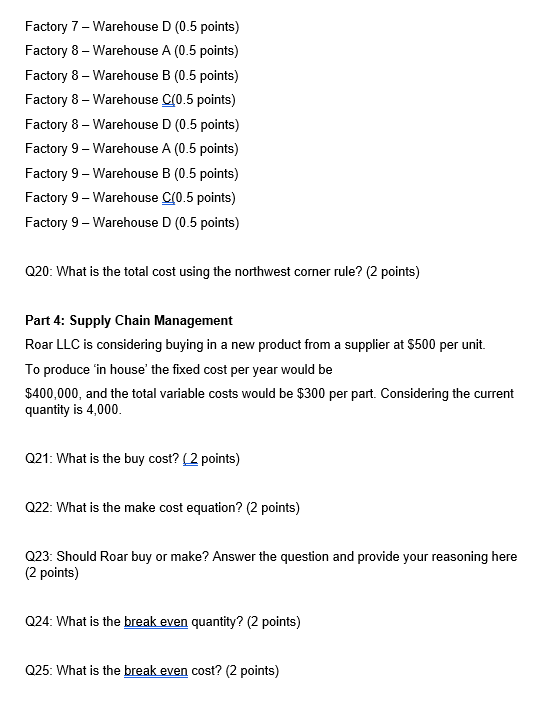

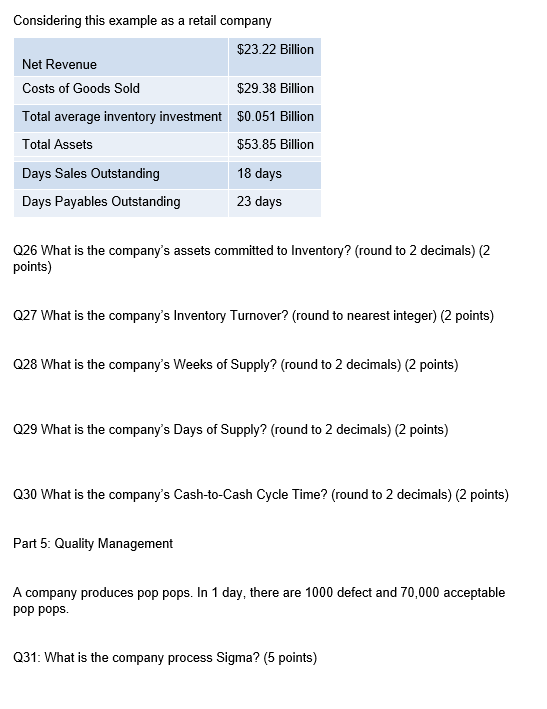

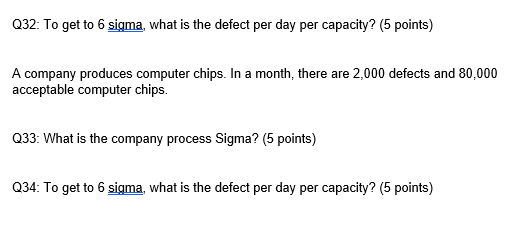

Part 1: ABC Classification Considering this table. Please set up the ABC Classification for each unit Product Code Unit Cost Annual Demand X51 5.84 1,200 KP25 5.4 1,110 31TW 1.12 896 79WAT 74.54 1,104 RTMS21 2 1,110 5215AR2 2.08 961 Q1: Which Product code(s) are in the A classification? (Multiple selection answer) (2pts) Q2 Which Product code(s) are in the B classification? (Multiple selection answer) (2pts) Q3 Which Product code(s) are in the classification? (Multiple selection answer) (2pts) Q4: What is the total cost of the inventory? (round to 2 decimals) (2pts) Q5: What are the cost of item(s) in Class A?(round to 2 decimals) (2pts) Q6: What is the percentage of annual value for class A?(round to 2 decimals) (2pts) Q7: What is the percentage of annual value for class B? (round to 2 decimals) (2pts) Q8: What is the percentage of annual value for class C?(round to 2 decimals) (2pts) Q9: Submit the Excel for ABC Classification here (4 points) (essay, allow upload) Part 2 EOQ Olivia Budinger is the manager a large car tires company with a central inventory operation. Olivia's fastest-moving inventory item has a demand of 6,000 units per year. The cost of each unit is $100, and the inventory carrying cost is $10 per unit per year. The average ordering cost is $30 per order. It takes about 5 days for an order to arrive, and the demand for 1 week is 120 units. Assuming 250 working days per year for this problem Q10: What is the EOQ? (round up to the nearest integer) (4 points) Q11: What is the optimal number of orders per year? (use previous rounded numbers if necessary, round up to the nearest integer) (2 points) Q12 What is the optimal number of days in between any two orders? (use previous rounded numbers if necessary, round up to the nearest integer) (2 points) Q13 What is the total cost of ordering and holding inventory? use previous rounded numbers if necessary, round to 2 decimals) (2 points) Olivia thinks the cost is too high and she has negotiated for a better term from the supplier. She receives a 10% discount on all the costs. However, the supplier also said it will take 8 days to deliver. Q14: What is the new EOQ? (round up to the nearest integer) (2 points) Q15: What is the new optimal number of orders per year? (use previous rounded numbers if necessary, round up to the nearest integer) (2 points) Answer: 32 Q16 What is the optimal number of days in between any two orders? (use previous rounded numbers if necessary, round up to the nearest integer) (2 points) answer: 8 Q17 What is the total cost of ordering and holding inventory? use previous rounded numbers if necessary, round to 2 decimals) (2 points) Q18: With the lower cost but longer delivery time, is it a good deal to take? (short answer) (2 points) Part 3: Transportation Problem Solve the problem below with the Northwest cor rule From To Warehouse Warehouse Warehouse Warehouse Factory A B Capacity Factory 1 Cost:55 Cost:S3 Cost:S5 Cost:S1200 Factory 2 Cost:S2 Cost: 95 Cost:$7 Cost:$2550 Factory 3 Cost:S4 Cost:S1 Cost:$3 Cost:$4400 Factory 4 Cost:$10 Cost:S1 Cost: S1 Cost: S9 250 Factory 5 Cost:$1 Cost:56 Cost:58 Cost:99 300 Factory 6 Cost:S3 Cost:$8 Cost:99 Cost: $ 7150 Factory 7 Cost: 54 Cost:S9 Cost:S12 Cost:S6 500 Factory 8 Cost:55 Cost:$4 Cost:S5 Cost:S1 850 Factory 9 Cost:$8 Cost:52 Cost:53 Cost:S3 1000 Warehouse 500 1600 1200 900 4200 Requirement Q19) Fill out the blanks below (multiple answers, 18 points): Factory 1 - Warehouse A (0.5 points) Factory 1 - Warehouse B (0.5 points) Factory 1 - Warehouse C(0.5 points) Factory 1 - Warehouse D (0.5 points) Factory 2 - Warehouse A (0.5 points) Factory 2 - Warehouse B (0.5 points) Factory 2 - Warehouse C(0.5 points) Factory 2 - Warehouse D (0.5 points) Factory 3 - Warehouse A (0.5 points) Factory 3 - Warehouse B (0.5 points) Factory 3 - Warehouse C10.5 points) Factory 3 - Warehouse D (0.5 points) Factory 4 - Warehouse A (0.5 points) Factory 4 - Warehouse B (0.5 points) Factory 4 - Warehouse C(0.5 points) Factory 4 - Warehouse D (0.5 points) Factory 5 - Warehouse A (0.5 points) Factory 5 - Warehouse B (0.5 points) Factory 5 - Warehouse C10.5 points) Factory 5 - Warehouse D (0.5 points) Factory 6 - Warehouse A (0.5 points) Factory 6 - Warehouse B (0.5 points) Factory 6 - Warehouse C10.5 points) Factory 6 - Warehouse D (0.5 points) Factory 7 - Warehouse A (0.5 points) Factory 7 - Warehouse B (0.5 points) Factory 7 - Warehouse C(0.5 points) Factory 7 - Warehouse D (0.5 points) Factory 8 - Warehouse A (0.5 points) Factory 8 - Warehouse B (0.5 points) Factory 8 - Warehouse C(0.5 points) Factory 8 - Warehouse D (0.5 points) Factory 9 - Warehouse A (0.5 points) Factory 9 - Warehouse B (0.5 points) Factory 9 - Warehouse C(0.5 points) Factory 9 - Warehouse D (0.5 points) Q20: What is the total cost using the northwest corner rule? (2 points) Part 4: Supply Chain Management Roar LLC is considering buying in a new product from a supplier at $500 per unit. To produce in house the fixed cost per year would be $400,000, and the total variable costs would be $300 per part. Considering the current quantity is 4,000 Q21: What is the buy cost? (2 points) Q22: What is the make cost equation? (2 points) Q23: Should Roar buy or make? Answer the question and provide your reasoning here (2 points) Q24: What is the break even quantity? (2 points) Q25: What is the break even cost? (2 points) Considering this example as a retail company $23.22 Billion Net Revenue Costs of Goods Sold $29.38 Billion Total average inventory investment $0.051 Billion Total Assets $53.85 Billion Days Sales Outstanding 18 days Days Payables Outstanding 23 days Q26 What is the company's assets committed to Inventory? (round to 2 decimals) (2 points) Q27 What is the company's Inventory Turnover? (round to nearest integer) (2 points) Q28 What is the company's Weeks of Supply? (round to 2 decimals) (2 points) Q29 What is the company's Days of Supply? (round to 2 decimals) (2 points) Q30 What is the company's Cash-to-Cash Cycle Time? (round to 2 decimals) (2 points) Part 5: Quality Management A company produces pop pops. In 1 day, there are 1000 defect and 70,000 acceptable pop pops. Q31: What is the company process Sigma? (5 points) Q32: To get to 6 sigma, what is the defect per day per capacity? (5 points) A company produces computer chips. In a month, there are 2,000 defects and 80,000 acceptable computer chips. Q33: What is the company process Sigma? (5 points) Q34: To get to 6 sigma, what is the defect per day per capacity? (5 points)